A mini excavator is a versatile machine, but when you attach a hydraulic hammer to its boom, you transform it into a precision demolition tool. This powerful combination can access job sites that larger equipment simply cannot reach, making it an indispensable asset.

This guide will explore how the hydraulic hammer mini excavator combination is a game changer for projects ranging from urban demolition and road repairs to breaking through solid rock in challenging terrain.

Turn Your Mini Excavator Into a Demolition Powerhouse

Selecting the right hydraulic hammer and operating it correctly is critical for maximizing job site efficiency. It is the key to achieving a significant return on investment, turning a compact digger into a multi functional demolition and breaking machine.

The primary advantage of this setup is its ability to deliver immense breaking force in confined spaces. Consider removing a concrete patio in a small backyard or performing selective demolition inside a building. The mini excavator's agility allows you to apply that power precisely where it's needed, without causing collateral damage. This level of surgical precision is impossible with larger, less maneuverable equipment.

What New Jobs Can You Take On?

Pairing a hydraulic hammer with your mini excavator opens up a new range of projects that were previously difficult or required different machinery. A single machine can now handle more project phases, from initial demolition to final site preparation.

Here are a few of the capabilities you will unlock:

- Urban Demolition: Safely break down concrete pads, foundations, and retaining walls in tight urban spaces where noise and vibration must be minimized.

- Road and Infrastructure Repair: Make quick work of old asphalt and concrete for patching potholes or replacing curbs and gutters.

- Trenching in Tough Ground: Lay utility lines through rock, shale, or frozen earth. A hammer can break through surfaces where a bucket would merely scrape.

- Landscaping and Site Prep: Break up large boulders and clear rocky ground to prepare a site for new construction or landscaping projects.

This versatility extends to specialized equipment. Amphibious excavators, for instance, use hydraulic attachments to tackle unique challenges in environments like swamps and wetlands. Outfitting a machine like the Wilco Marsh Runner with the right tools fundamentally changes how projects are approached in these difficult terrains. You can see how the most popular Wilco Marsh Runner attachments enable crews to work in previously inaccessible locations.

How a Hydraulic Hammer Actually Works

The incredible force generated by a hydraulic hammer is a product of sophisticated engineering. It functions like a powerful, automated chisel, powered entirely by your mini excavator's hydraulic system. This synergy is what makes the hydraulic hammer mini excavator combination so effective on the job site.

The process begins when the operator engages the attachment. The mini excavator’s hydraulic pump sends high pressure oil through the hoses and into the hammer. This fluid is the lifeblood of the operation, carrying the energy needed to break through the toughest materials. It is an efficient closed loop system that converts fluid pressure into percussive force.

The Power Stroke and Piston Action

Inside the hammer's housing, a control valve directs the flow of hydraulic fluid. It opens to send a surge of oil that drives a heavy steel piston downward at high speed. The piston’s sole purpose is to strike the tool bit, the chisel or moil point that performs the breaking action on rock or concrete.

This sequence occurs almost instantaneously, delivering a massive impact. The control valve then reverses the flow, retracting the piston to prepare for the next strike. This cycle can repeat hundreds of times per minute, creating the continuous, shattering force for which these attachments are known.

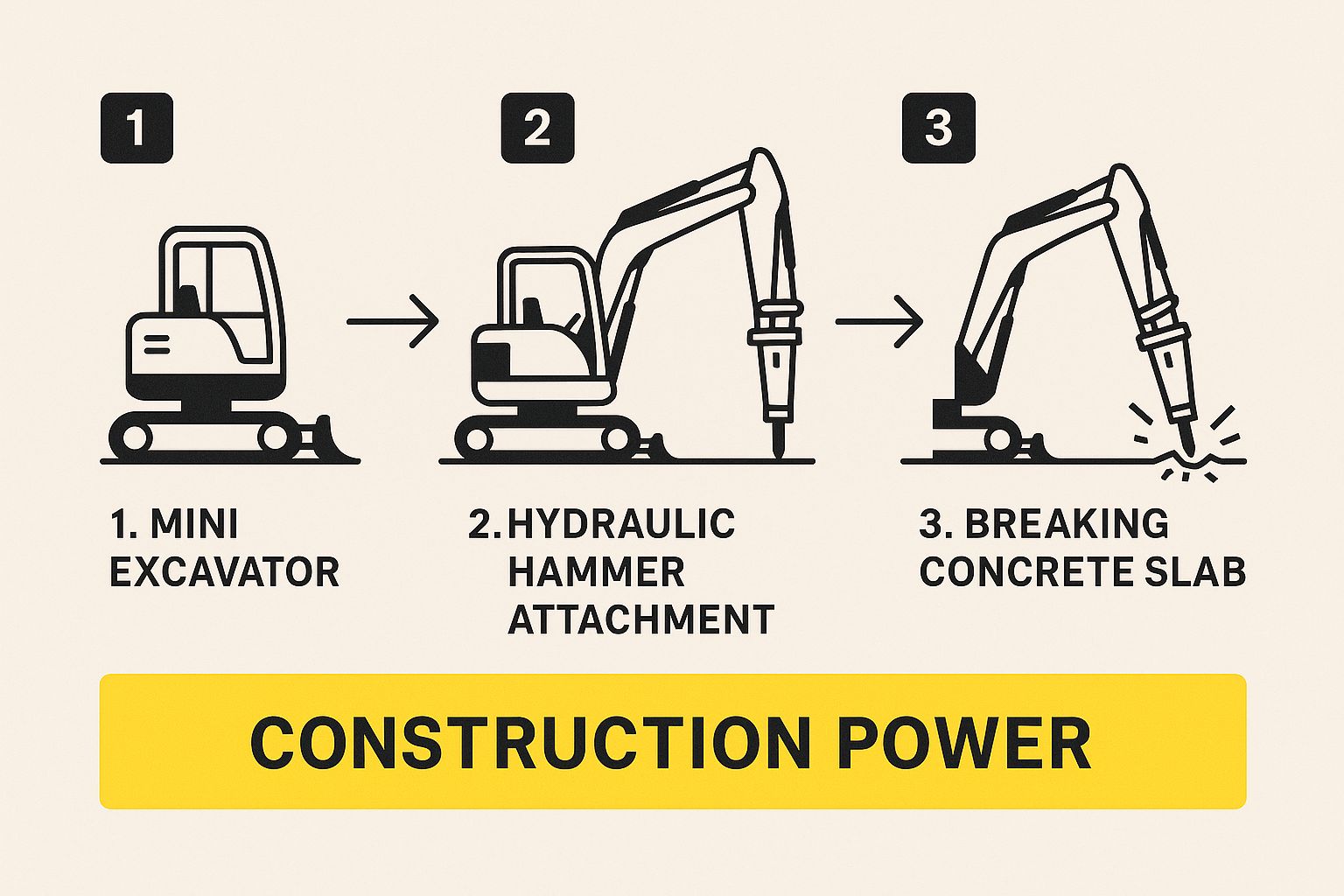

The image below illustrates how this power translates into real world productivity.

As you can see, the hydraulic hammer is often the key to turning a mini excavator from a digging machine into a primary demolition tool.

The Role of Nitrogen Gas

While hydraulic fluid pushes the piston down, nitrogen gas is often used to retract it and prepare it for the next blow. Most modern hammers feature a chamber at the top filled with highly pressurized nitrogen.

As the piston retracts after a strike, it compresses this nitrogen gas. The compressed gas then acts like a powerful spring, expanding to add a significant boost of extra force and speed to the piston’s next downward stroke.

This gas assisted design is a crucial innovation. It not only increases the impact energy of each blow but also helps absorb the operational shock, which reduces wear and tear on both the hammer and the mini excavator.

This clever engineering is a major reason for the tool's popularity. The global hydraulic hammer market, valued at approximately USD 1.49 billion, is projected to reach USD 2.64 billion by 2034. If you are interested in market trends, you can review the full report on hydraulic hammer growth to see the data driving this demand.

Choosing the Right Hydraulic Hammer

Selecting the right hydraulic hammer is a critical decision that directly impacts job site performance, operator safety, and the longevity of your equipment. A correct match makes your hydraulic hammer mini excavator a powerhouse. An incorrect one leads to poor results and, potentially, catastrophic equipment damage.

Taking the time to make an informed choice helps avoid costly mistakes and transforms your mini excavator into a reliable, high performance tool ready for the toughest breaking jobs.

Key Compatibility Factors

To achieve the perfect pairing between excavator and hammer, you must match three core specifications. These are non negotiable for a successful and safe setup.

- Operating Weight: A good rule of thumb is that the hammer's weight should be approximately 10 to 15% of your excavator's total operating weight. A hammer that is too heavy will stress the boom and risk tipping the machine. One that is too light will lack the necessary impact force, reducing productivity.

- Hydraulic Flow Rate (GPM): This measures how much hydraulic oil your excavator’s pump can deliver per minute. Every hammer is designed for a specific flow rate to cycle its piston correctly. An incorrect GPM can starve the hammer of power or overwhelm it, causing overheating.

- System Pressure (PSI): This is the force behind the hydraulic fluid. The hammer requires a specific PSI range to operate at peak performance. Mismatched pressure means you are either not hitting hard enough or you are putting extreme stress on the hammer's internal seals and components.

Hydraulic Hammer Selection Checklist

Use this checklist to confirm that the hammer you are considering is a true match for your mini excavator.

| Compatibility Check | Why It's Critical for Performance | Where to Find This Information |

|---|---|---|

| Excavator Weight vs. Hammer Weight | Ensures stability and proper force transfer. A mismatch can cause unsafe operation or damage the excavator's boom. | Your excavator's operator manual or spec sheet; the hammer's product specifications. |

| Hydraulic Flow (GPM) | Guarantees the hammer cycles at the correct speed for optimal impact. Incorrect flow leads to poor performance or overheating. | Your excavator's hydraulic system specs; the hammer's required GPM range. |

| Operating Pressure (PSI) | Delivers the necessary force for each blow. Wrong pressure can result in weak hits or damage to internal hammer components. | Your excavator's hydraulic relief settings; the hammer's required PSI range. |

| Mounting Bracket & Pin Size | A secure, direct fit is essential for safety and efficiency. A loose or improper fit causes excess wear and is a major safety hazard. | Measure your machine's pin diameter and ear width; check against the hammer's coupler specs. |

Verifying these four points before purchase will prevent significant issues later. This critical data is available in your excavator’s operator manual and should be cross referenced with the hammer's specification sheet. For specialized gear like amphibious equipment, where hydraulic demands can be unique, you can review different equipment models to see how their systems are configured.

Matching Impact Energy to the Job

Once you have confirmed technical compatibility, the next step is to consider the hammer's impact energy class. This rating, usually measured in foot pounds, indicates the force the hammer delivers with each strike. The right choice depends entirely on the material you need to break.

A common mistake is assuming that more power is always better. Using an oversized hammer for light duty work is inefficient, shatters material unnecessarily, and creates additional cleanup and safety hazards.

For example, a hammer with a lower impact energy is ideal for breaking a thin residential concrete slab or smaller rocks in a trench. A mid range model offers versatility for general demolition or trenching through tough, rocky soil. However, when you are facing heavily reinforced concrete or breaking solid quarry rock, only a high impact energy hammer has the force required to complete the job efficiently.

Aligning the hammer's power with your project's demands allows you to work smarter, not just harder.

Real-World Hydraulic Hammer Applications

Technical specifications are only meaningful when a tool performs on a real job site. The hydraulic hammer and mini excavator combination excels in situations requiring both power and precision in limited space. Its ability to tackle jobs that larger machines cannot is why it has become so indispensable in industries like construction and land reclamation.

Market data reflects this demand. With tens of thousands of new mini excavators sold globally each year, the appetite for high performance attachments is strong. Urban growth and infrastructure renewal projects are major drivers of this trend. You can explore more data on top-selling mini excavators to see the latest industry figures.

Precision Urban Demolition

Demolishing structures in a dense urban environment requires a surgical approach. You must remove the old without disturbing adjacent properties. A mini excavator with a hydraulic hammer is the perfect instrument for this delicate work, allowing operators to chip away at concrete foundations, patios, and retaining walls with controlled, powerful blows.

The machine's small footprint allows it to access tight alleys and backyards, while the hammer delivers pinpoint impacts. This drastically reduces ground vibrations and the risk of damaging neighboring property, making it a go to for residential renovations and smaller commercial demolitions.

Road and Bridge Repair

Maintaining our infrastructure often involves breaking out old, cracked pavement or concrete. A hydraulic hammer attachment makes quick work of this task, pulverizing asphalt and reinforced concrete for road patching, curb replacement, or bridge deck repairs.

Unlike massive breakers that can send cracks far beyond the repair zone, this setup allows crews to focus the breaking force precisely where it is needed. This leads to a more efficient workflow, saves on materials and time, and helps reopen roads and bridges to traffic sooner.

Trenching in Tough Ground

Laying utility lines for water, gas, or fiber optics often involves unpredictable subsurface conditions. A standard bucket is ineffective against solid rock or heavily compacted soil, but a hydraulic hammer can break right through. It fractures stubborn material so it can be removed, allowing the trenching to proceed.

This capability is a game changer for projects in new developments or rural areas where challenging ground is common. This need for specialized tools is mirrored in other tough environments. For example, using the right equipment for dredging is critical for projects involving hard riverbeds or packed sediment. By breaking up difficult ground, a hammer helps keep projects on schedule and within budget.

Essential Maintenance to Prevent Downtime

A well maintained hydraulic hammer is a reliable one. Proactive upkeep for your hydraulic hammer mini excavator is not just about avoiding breakdowns, it is about maximizing the life of your attachment and preventing the high costs of unexpected downtime.

The best way to protect your investment is by establishing a simple, consistent maintenance routine. Catching small issues early prevents them from escalating into project halting failures. This ensures your equipment is always ready for the job at hand.

Daily and Weekly Maintenance Checks

A few minutes of consistent care can make a significant difference. Key checks before startup and during operation can prevent 70 to 80% of common attachment failures.

Here is what you should be doing every day:

- Grease the Tool Bit: After every hour or two of operation, apply fresh grease to the tool bit and its bushings. This is crucial for reducing the friction and heat that can quickly destroy expensive components.

- Inspect Hydraulic Hoses: Conduct a visual inspection of all hoses. Look for cracks, bulges, or any signs of leaks. A burst hose not only stops work but also poses a serious safety risk.

- Visual Structural Inspection: Walk around the hammer and look for any cracks in the housing or mounting brackets. The immense forces generated can cause stress fractures that need to be identified early.

Remember, maintenance extends beyond the machine. Protecting operators from risks like occupational hearing loss is a non negotiable part of working with powerful equipment.

Common Operator Mistakes to Avoid

Even the best maintained hammer will not last long if operated incorrectly. Training operators to avoid common bad habits is as vital as your greasing schedule. These mistakes place unnecessary stress on both the hammer and the excavator.

The single most destructive operator error is blank firing. This occurs when running the hammer without the tool bit pressed firmly against a surface. It sends a massive shockwave back into the hammer, causing severe internal damage.

Operators must also understand that a hammer is not a pry bar. Using the attachment to sweep material or pry rocks apart can quickly lead to a bent tool bit and a damaged excavator boom. For specialized equipment working under unique stress, expert service is key. Wilco provides comprehensive service to keep your machinery running at peak performance.

Finding the Right Partner for the Long Haul

Choosing the right hydraulic hammer is a critical first step, but long term success requires a reliable equipment partner. The best attachment is of little value if it is frequently down for repairs. At Wilco Manufacturing, our deep experience with heavy machinery, including complex amphibious systems, gives us a clear understanding of the pressures your projects face.

A good partner does more than sell you equipment. We provide the genuine parts, hands on service, and practical advice that keep you operational. This support is what minimizes downtime and maximizes your return on investment. The industry's growth reflects this need. The global hydraulic breaker market is projected to grow from USD 3.83 billion to USD 8.92 billion by 2034. You can review the full hydraulic breaker market analysis for more details.

A successful project is about more than having the right tool. It is about having a dedicated partner who understands your operational challenges and provides the solutions to overcome them, from initial selection to long term maintenance.

Your success drives us. Whether you are breaking concrete in an urban center or managing a complex demolition project, having the right team supporting you makes all the difference.

Let us discuss your project needs. Our specialists can help you determine exactly what you need to ensure your hydraulic hammer mini excavator performs at its best, day in and day out.

Frequently Asked Questions

When adding a hydraulic hammer to your mini excavator fleet, you will likely have questions. Getting the right answers is key to making a smart purchase and, more importantly, operating the equipment safely and effectively. Let's cover some of the most common inquiries from operators and project managers.

Greasing and Tool Selection

How often should I really be greasing my hydraulic hammer?

This is arguably the most important maintenance task. For most applications, you should grease the tool bit and its bushings every one to two hours of continuous operation. While this may seem frequent, it is essential for preventing the intense friction and heat that can rapidly destroy expensive components. Always consult the manufacturer's specific recommendations for your model.

Can I just use any chisel point on my hammer?

No, using the correct tool for the application is non negotiable for performance and safety. Each tool bit is engineered for a specific purpose.

- A moil point is the standard tool for general concrete and rock breaking.

- A chisel bit is designed for trenching, cutting lines, or shaping material.

- A blunt tool is used for secondary breaking, such as smashing oversized boulders into smaller, more manageable pieces.

Using the wrong tool will not only slow down your work but also place unnecessary stress on the hammer.

Operational Best Practices

What exactly is "blank firing" and why is it so bad for the hammer?

Blank firing occurs when you operate the hammer without the tool bit pressed firmly against a solid surface. The piston fires forward with nothing to absorb its immense energy, sending a damaging shockwave back through the hammer's internal components. Even a single blank fire can cause catastrophic damage. It is one of the most destructive and avoidable operator mistakes.

How can I tell if the nitrogen charge in my hammer is getting low?

You will notice a significant drop in impact power. The hammer will not hit as hard, it may sound different with a duller thud instead of a sharp crack, and you will break material much more slowly.

If you suspect the charge is low, stop work and have it checked by a qualified technician. Recharging the nitrogen will restore the hammer's performance. Keeping equipment running often means managing parts availability and procurement. Learning about solid supply chain disruption management strategies can be a great help in keeping your entire operation on schedule.

At Wilco Manufacturing, we provide the tough, reliable equipment and expert support you need to get the job done. Whether you require a new amphibious excavator, a rental for a specialized project, or dependable parts and service, our team is here to help.

Contact us today to discuss your project needs and discover the Wilco difference.