Effective construction machinery maintenance is far more than fixing what's broken. It's a proactive strategy to protect your most valuable assets, keep projects on schedule, and safeguard your profits by preventing failures before they happen. For decision-makers in demanding industries like dredging, pipeline installation, and environmental cleanup, moving from a reactive to a preventive mindset separates a resilient, competitive operation from one constantly battling downtime. This guide provides actionable insights for maintaining your fleet, with a special focus on the unique challenges faced by amphibious equipment.

Beyond Repairs: The Strategic Value of Proactive Maintenance

The single most impactful change for your fleet’s health and your bottom line is shifting away from a "fix-it-when-it-breaks" mentality. A proactive maintenance strategy is a powerful investment, not just a budget item. This is especially true for specialized equipment like amphibious excavators, which operate in harsh, corrosive environments where mechanical failure is not an option.

A planned approach to upkeep delivers clear returns in several key areas:

- Enhanced Operational Safety: A well-maintained machine is a safer machine. Regular checks on hydraulic lines, structural integrity, and safety systems are crucial for preventing accidents caused by sudden component failure.

- Increased Profitability: Proactive maintenance minimizes unexpected downtime, one of the largest hidden costs in any construction or dredging project. Every hour a machine is idle represents lost revenue and project delays.

- Extended Equipment Lifespan: Consistent care protects your investment. By identifying and addressing minor wear and tear on critical components like amphibious hydraulic undercarriages early, you prevent small issues from escalating into catastrophic failures.

The Impact of Reactive vs. Proactive Thinking

Comparing these two philosophies side by side reveals the stark difference between a constant scramble and a calculated plan for success.

Maintenance Approach Comparison: Reactive vs. Proactive

| Metric | Reactive Maintenance (Break-Fix) | Proactive Maintenance (Preventive/Predictive) |

|---|---|---|

| Downtime | Unplanned and often lengthy, occurring at the worst possible times. | Scheduled during off-hours, minimized, and predictable. |

| Repair Costs | High due to emergency repairs, overtime labor, and rush shipping on parts. | Lower, as parts are ordered in advance and maintenance is planned. |

| Safety | Increased risk of accidents from sudden equipment failure. | Significantly lower risk due to regular inspections and component replacement. |

| Lifespan | Equipment life is often shortened by repeated major failures. | Maximized equipment lifespan through consistent care and early intervention. |

| Productivity | Volatile. Project timelines are frequently disrupted. | Consistent and reliable. Projects stay on schedule. |

The proactive approach is not just about avoiding problems. It’s about building a more stable, predictable, and profitable business from the ground up.

Adopting a Culture of Prevention

Building a culture of prevention transforms your maintenance program into a competitive advantage. It starts with empowering operators to perform daily checks and encouraging them to report even minor issues without hesitation. This mindset ensures your machinery performs reliably on the most challenging job sites, whether you're laying pipeline in a swamp or tackling a complex environmental cleanup.

The industry is embracing this shift. The global market for construction equipment maintenance and repair, valued at USD 24.1 billion in 2025, is projected to reach USD 35.9 billion by 2035, driven by a growing fleet and the need for dependable upkeep. Innovations like the benefits of 3D printing for on-demand production of replacement parts are also supporting this forward, thinking maintenance strategy by reducing downtime.

A proactive maintenance plan doesn't just save money on repairs; it builds a reputation for reliability. When clients know your equipment is dependable, you win more bids and complete projects on schedule, reinforcing your position as an industry leader.

At Wilco Manufacturing, our expertise extends beyond building robust amphibious machines. With decades of firsthand experience, we understand the unique maintenance demands of equipment operating in harsh environments. When you partner with us, you gain more than a machine. You gain the knowledge and support to build a maintenance strategy that protects your assets and your business.

Building Your Daily and Weekly Inspection Routine

Effective maintenance is not about a single, massive annual overhaul. It is built on the disciplined habits your operators practice every day. A structured routine for daily and weekly inspections is the foundation of a healthy fleet, turning your crew from users into guardians of your most valuable assets. These checks are your first line of defense, designed to spot small irregularities before they become project, halting failures.

The goal is to focus on what keeps the machine operational. A daily check should be quick yet thorough, covering non, negotiable vitals. This process is about operators developing a true connection with their equipment, learning its normal behavior so they can instantly spot subtle changes. A hydraulic fluid level that is slightly lower than yesterday or a new drip stain under the engine are early warnings of bigger trouble.

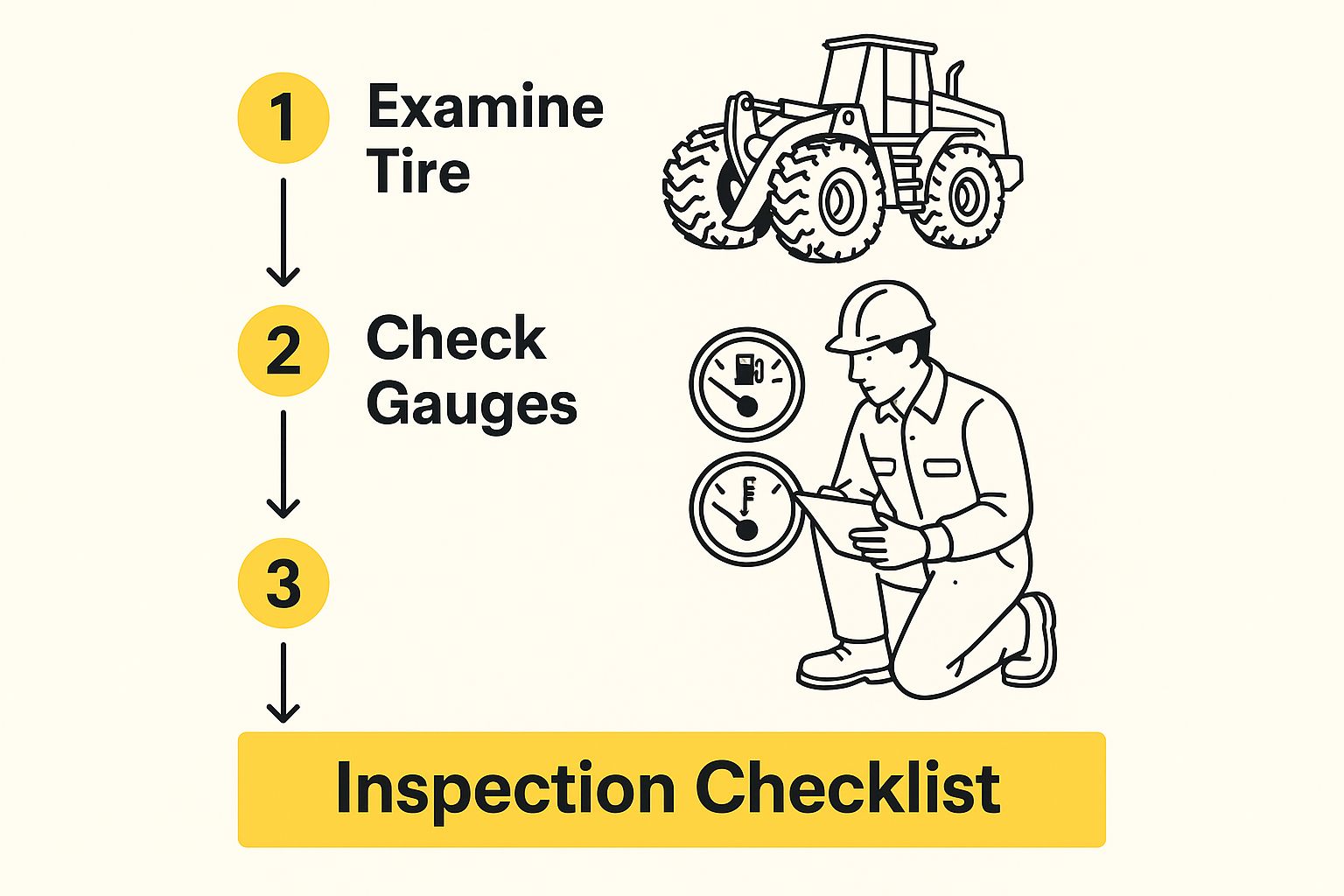

This visual guide breaks down the key checkpoints for a solid daily inspection, clarifying what matters most for reliability.

A visual reference like this helps the entire team internalize the critical steps, ensuring nothing is overlooked before a shift begins.

The Critical Daily Walkaround

Before an operator turns the key, a comprehensive walkaround is a vital five, to, ten, minute investment.

- Check Your Fluids: Visually inspect engine oil, hydraulic fluid, coolant, and fuel levels. Low levels could indicate a leak or high consumption, both requiring immediate attention.

- Hunt for Leaks: Scan the ground beneath the machine, then examine every hose, cylinder, and fitting for signs of fluid. A small hydraulic leak can quickly lead to system contamination or failure under pressure.

- Inspect the Undercarriage and Pontoons: Look for fresh damage, loose bolts, or debris packed around tracks, rollers, and pontoons. This is non, negotiable for amphibious equipment, where a compromised pontoon affects the machine’s stability and buoyancy.

- Give it a General Once-Over: Check for bent or cracked components, ensure all safety guards are in place, and test lights and alarms. These simple checks can prevent serious accidents.

With equipment fleets aging, these routines are more critical than ever. The global construction equipment repair market reached approximately USD 34.6 billion in 2024 and is expected to grow by 4.3% annually through 2034 as companies work to keep older machines in service. In this climate, a disciplined daily check provides a significant competitive edge.

The Deeper Weekly Inspection

While daily checks ensure immediate readiness, weekly inspections address long, term wear and tear. This is when your team performs the hands, on tasks that extend the life of your equipment.

A machine that is washed daily and greased weekly will outlast a neglected one by years, not months. This is especially true in saltwater environments, where corrosion can destroy components with alarming speed.

Consider a Wilco amphibious excavator on a saltwater dredging project. The saline environment is incredibly corrosive. A simple freshwater rinse of the undercarriage and pontoons at day's end is not just "good practice," it's essential for preventing catastrophic corrosion that can seize track components and weaken structural welds.

Your weekly checklist should expand on the daily routine with more in, depth tasks:

- Hit Every Grease Point: Systematically lubricate every zerk fitting according to the manufacturer's manual. This forces out contaminants like dirt and water while keeping pins and bushings moving smoothly.

- Clean Your Filters: Inspect and clean the pre, cleaner and air filters. Clogged filters starve the engine of air, reducing power, increasing fuel consumption, and accelerating engine wear.

- Check Track Tension: Track tension is not a "set it and forget it" adjustment. It must match ground conditions. Tracks that are too tight cause premature wear on pins, bushings, and sprockets. Tracks that are too loose risk de, tracking, a dangerous and time, consuming repair. Adjust sag to the manufacturer’s specifications for the material you are working in, from soft mud to abrasive sand.

Empowering your team with clear, actionable checklists shifts the entire culture from reactive repairs to proactive care. These routines are the backbone of a successful maintenance program, ensuring your equipment is ready to perform, day in and day out.

Advanced Care for Hydraulic and Undercarriage Systems

While daily walkarounds form the bedrock of good maintenance, the hydraulic system and undercarriage demand a deeper level of attention. These are the heart and legs of your machine. When they fail, the consequences are significant and costly.

Proper construction machinery maintenance for these critical systems is about more than just a checklist. It requires a true understanding of how they function, especially under the relentless stress of amphibious environments.

Protecting the Hydraulic System

The lifeblood of your excavator is its hydraulic fluid, and maintaining its cleanliness is your top priority. An estimated 70% of all hydraulic system failures can be traced back to fluid contamination.

Contaminants like dirt, water, and metal particles act like liquid sandpaper circulating through your machine’s veins. They erode precision, engineered pumps, motors, and valves, causing a slow degradation of performance that ends in a catastrophic breakdown.

The best defense is a proactive fluid analysis program.

- Consistent Fluid Sampling: Establish a routine of pulling hydraulic fluid samples at regular intervals, typically every 500 operating hours. This provides a clear window into the system's internal health.

- Interpreting the Results: Your lab report is a roadmap. High particle counts indicate internal component wear, while the presence of water signals a risk of corrosion and fluid degradation.

- Strategic Filter Replacement: Adhere strictly to filter change schedules. Clean filters are your final line of defense, capturing destructive particles before they can damage high, value components.

Understanding the complexity of modern hydraulics is key. Examining components like Hydrastar hydraulic products offers an appreciation for the precision involved.

Mastering Undercarriage and Pontoon Health

A machine's undercarriage always takes a beating, but on amphibious equipment, that abuse is intensified. Pontoons and track systems are constantly submerged in water, mud, and abrasive sand, making corrosion and wear ever, present threats. This is why a meticulous inspection and adjustment routine is critical.

Train your crew to spot the telltale signs of trouble:

- Rollers: Look for flat spots or uneven wear, which are classic symptoms of a seized or misaligned roller.

- Chains: A stretched or "snaky" chain is a clear visual cue that it is nearing the end of its service life.

- Sprockets: Examine the teeth. As they wear, they become sharp and hooked, a shape that dramatically accelerates chain wear.

A common and costly mistake is to "set and forget" track tension. The correct tension depends entirely on ground conditions, and failure to adjust it will accelerate undercarriage wear and risk de, tracking.

Adjusting track tension is one of the most effective ways to extend undercarriage life. In soft mud or sand, run the tracks slightly looser to help clear material. On hard, stable ground, a tighter track prevents slapping and unnecessary wear on rollers.

Even the most robustly engineered systems, like Wilco’s amphibious hydraulic undercarriages, depend on this type of smart, environment, specific care to deliver their full service life.

Case Study: Land Reclamation Project Downtime

On a major land reclamation project, a contractor used a fleet of amphibious excavators to reshape a coastal wetland. The ground conditions shifted from soupy mud to abrasive sand almost overnight. The crew, pushing to meet a deadline, overlooked daily undercarriage cleanouts and track tension adjustments.

Within two weeks, a machine de, tracked in a critical work zone, halting that part of the operation. The recovery in the unstable mud was a logistical nightmare, costing the project two full days of downtime and tens of thousands of dollars in lost revenue.

This incident served as a wake, up call. The site manager immediately implemented a new protocol. Every machine received a thorough undercarriage washdown at the end of each shift, and operators checked and adjusted track tension based on the next day's work plan.

The result? Over the next six months, the project experienced zero de, tracking incidents. A final inspection also revealed significantly less premature wear on chains and sprockets. This simple change not only prevented downtime but also directly extended component life, saving a fortune in future repairs. It is a perfect example of how specialized care pays for itself.

Implementing a Modern Predictive Maintenance Program

It’s time to move beyond reactive maintenance. Instead of just fixing equipment when it breaks, a modern predictive maintenance program focuses on anticipating problems before they occur. This strategic shift is less about checklists and more about actively engineering reliability into your operation.

The strategy hinges on meticulous digital record, keeping. Every service interval, parts replacement, and fluid analysis log contributes to a rich historical dataset for each machine. This information is the key to unlocking powerful, cost, saving insights.

Using Data to See the Future

The goal is to move from generalized schedules to decisions based on hard data. Every piece of equipment, especially a specialized asset like an amphibious excavator, tells a unique story through its operational data.

A solid predictive maintenance program is built on smart data analysis. Mastering powerful data extraction techniques is crucial for pulling accurate information from all your sources to feed predictive models.

With this data, you can spot subtle wear patterns and correlations invisible to the naked eye. For instance, you might discover that a specific hydraulic pump model consistently shows a slight pressure drop approximately 50 hours before a common failure. That insight is invaluable. It allows you to schedule a replacement during planned downtime instead of scrambling to fix a breakdown during a critical dredging job.

Telematics: Your Eyes and Ears in the Field

Technology like telematics transforms maintenance strategy. These systems provide a constant stream of real, time data from your equipment, no matter its location. You get:

- Machine Hours: Precise usage data allows for scheduling maintenance based on actual work, not just the calendar.

- Fuel Consumption: A sudden change in fuel burn can be an early warning of an engine or hydraulic system issue.

- Fault Codes: Receive instant alerts when the machine’s onboard computer detects a problem, enabling immediate assessment.

- Operating Parameters: Monitor engine temperature, hydraulic pressure, and other vitals to catch deviations from the norm.

This flow of information enables your team to schedule critical maintenance with surgical precision. It’s the difference between proactively replacing a wearing part during a scheduled service and having a machine fail unexpectedly, halting a project and incurring emergency repair costs.

A well, structured predictive maintenance program turns raw data into actionable intelligence.

Key Elements of a Predictive Maintenance Program

| Component | Description | Benefit |

|---|---|---|

| Data Collection | Using sensors and telematics to gather real-time operational data from the machine. | Provides a constant, accurate stream of information without manual input. |

| Data Analysis | Applying algorithms and analytical tools to identify patterns, anomalies, and trends. | Uncovers hidden issues and predicts potential failures before they occur. |

| Actionable Alerts | Creating a system that notifies maintenance teams of specific issues with clear instructions. | Turns complex data into simple, direct tasks for technicians. |

| Continuous Feedback | Integrating work order data back into the system to refine predictive models. | Makes the system smarter and more accurate over time. |

By building a program around these core elements, you create a powerful, self, improving system that actively protects your assets and your bottom line.

Predictive maintenance isn’t about fortune-telling. It’s about listening to what your machines are telling you through data and acting on that intelligence to control your own schedule, budget, and operational outcomes.

The sheer size of the construction equipment maintenance market highlights the importance of uptime. Estimated at roughly USD 150 billion in 2025, it’s expected to climb to over USD 250 billion by 2033. This growth is largely driven by an aging global fleet that requires smarter, more frequent attention. You can read the full research about construction equipment repair to get a deeper look at these trends.

By embracing a predictive program, you directly lower your total cost of ownership. You reduce unplanned downtime, optimize parts inventory, extend the life of major components, and run a more resilient and profitable operation. At Wilco Manufacturing, we engineer our amphibious systems for extreme durability. Pairing them with a smart, data, driven maintenance strategy ensures you achieve the maximum return on your investment, project after project.

Troubleshooting Common Issues Out in the Field

No matter how meticulous your maintenance plan, equipment will eventually have issues. It’s the nature of work in demanding fields like dredging, construction, and land reclamation. When a machine goes down in a remote location, your team’s ability to perform logical, safe diagnostics can mean the difference between a quick fix and a multi, day shutdown.

This is not about turning operators into mechanics overnight. It’s about equipping them with the knowledge to safely identify the root cause of a problem. When they call for support, they can provide precise information, saving everyone time, money, and frustration.

What to Do When Hydraulic Power Suddenly Disappears

A total loss of hydraulic power stops a job instantly. When an amphibious excavator suddenly can’t lift, swing, or travel, the problem could range from simple to severe. Before calling for a service truck, have your operator run through a quick diagnostic check.

First, check the hydraulic fluid. A low level in the reservoir is the classic sign of a leak. If it's low, the next step is a slow walkaround to carefully inspect every hydraulic line, cylinder, and fitting for wet spots or active drips.

If the fluid level is normal, the next suspect is the filters. A clogged hydraulic filter can starve the pumps, causing a massive drop in pressure and performance. Most modern machines have a filter bypass indicator that signals when a change is needed. This simple check can often solve the problem without any tools.

An operator who can report, "We've lost all hydraulic power. Fluid level is good, but the main filter light is on," gives a technician a significant head start. This is far more useful than a generic call about a "broken" machine.

Dealing with an Overheating Engine

An overheating engine is a critical issue that requires immediate attention to prevent severe damage. The moment an operator sees the temperature gauge enter the red zone, the only correct action is to safely shut the machine down and allow it to cool.

Once the engine has cooled enough for safe inspection, a few key checks can usually pinpoint the problem.

- Check the Coolant: Start with the basics. Is there enough coolant in the radiator and overflow tank? Low coolant is the most common cause of overheating.

- Clean the Radiator: Inspect the radiator fins. In the muddy environments where amphibious machines work, it is common for the radiator to become caked with mud and debris. This blocks airflow, turning the radiator into an insulator instead of a heat exchanger.

- Inspect Belts and Hoses: Check the fan belt for proper tension and signs of cracking or fraying. A loose or broken belt means the fan isn't spinning, preventing the engine from cooling itself. While there, squeeze the radiator hoses (when cool) to check for leaks, cracks, or soft spots.

These on, site steps often lead to a simple solution, like hosing off a clogged radiator, which can get the machine back to work in under an hour.

Investigating Strange Noises from the Undercarriage

New or unusual noises from the undercarriage, such as grinding, popping, or squealing, should be treated as serious warnings. These sounds are often the first sign of a problem with the tracks, rollers, or sprockets. Good construction machinery maintenance starts with teaching operators to listen to their machine.

As soon as a new noise appears, the first step is to clean the undercarriage and perform a thorough visual inspection. A loud bang can often be traced to a rock or piece of wood wedged between the track and a roller.

If no debris is found, look closer at the moving parts. Check each roller to ensure it spins freely, as a seized bearing will create significant noise. Examine the sprocket teeth for "hooking" or uneven wear, which can cause a popping sound as the track chain engages.

Finally, check the track tension. A track that is too loose will slap against the frame, while one that is too tight puts immense strain on every component, often causing a loud groaning or squealing noise. Walking your team through this simple process turns operators into the first line of defense for your fleet's health.

Finding the Right Partner for Your Equipment's Long-Term Health

Diligent construction machinery maintenance is the backbone of any successful operation. While your in, house crew may be excellent at handling daily checks and routine service, a true expert partner becomes an invaluable extension of your team when you face a major repair or need a specific OEM part immediately. This partnership is not just about fixing a problem, it’s about having a deep well of specialized knowledge on call.

More Than Just a Sale: Expert Support When It Counts

When diagnosing a complex hydraulic issue or planning a complete undercarriage rebuild, a manual is not enough. You need an expert who has seen it all before.

An experienced partner provides critical diagnostic support and technical advice tailored to your specific machine and its operating environment. This guidance prevents you from chasing phantom issues and spending money on incorrect fixes, ensuring the job is done right the first time.

A strong maintenance partnership turns a cost center into a competitive advantage. You get the right parts, the right expertise, and the right solutions to keep your projects on schedule and avoid crippling downtime.

At Wilco Manufacturing, we don't just build robust amphibious equipment. We stand behind our machines for their entire lifecycle, providing the expert guidance, genuine parts, and flexible rental options you need to keep your operation running smoothly.

Why Genuine Parts and Service Are Non-Negotiable

For high, performance, specialized machinery, the quality of replacement parts can make or break a project. Sticking with genuine OEM parts is the only way to guarantee a perfect fit and the material strength your equipment was engineered to have. A dedicated partner simplifies sourcing these essential components, eliminating the guesswork and risks associated with aftermarket parts that may not withstand operational stress.

Investing in expert support is one of the smartest decisions you can make for your fleet. It's about protecting your assets, maximizing uptime, and ensuring you are always ready for the next challenge. To see how we can support your fleet, take a look at our comprehensive Hydratrek service and support programs.

Common Questions We Hear in the Field

Even with the best maintenance plan, the real world presents challenges. Over the years, we've addressed nearly every question related to keeping specialized machines running. Here are a few of the most common inquiries and our straightforward answers.

How Often Should I Really Be Changing the Hydraulic Fluid?

Manufacturer manuals often suggest a ballpark figure, perhaps every 2,000 to 4,000 hours, but this is a guideline, not a strict rule. For an amphibious machine operating in water and humid conditions, the environment is the deciding factor.

Instead of a rigid schedule, a smarter approach is to pull a fluid sample for analysis every 500 hours. This simple test reveals the true condition of your fluid. Is there water contamination? Are particle counts rising? Are additives depleted? Catching these issues early prevents catastrophic pump failures and can often allow you to safely extend the fluid’s life, saving money in the long run.

What Are the First Red Flags for Undercarriage Wear?

You don't need a catastrophic failure to know something is wrong. The first signs are usually subtle, and training your operators to spot them is your best defense.

Look for a "scalloping" pattern on the edges of the track pads, a clear giveaway of uneven wear. Another telltale sign is when the tips of your sprockets start looking sharp and pointed instead of rounded. And don't just look, listen. Any new popping or grinding noises during travel could indicate a problem with pins or bushings. A quick walkaround after every shift can make all the difference.

Catching undercarriage wear early is the difference between a simple adjustment or component swap and a full, costly rebuild. It's about turning a minor expense into a major saving through vigilance.

Is It Okay to Use Aftermarket Parts for Repairs?

The temptation to save money with third, party parts is always present, but for critical systems, it’s a gamble not worth taking. When it comes to hydraulic pumps, motors, and undercarriage components, stick with Original Equipment Manufacturer (OEM) parts.

OEM parts are engineered to the exact tolerances and material specifications your machine was built with, guaranteeing a perfect fit, reliable performance, and operational safety. A non, OEM part might fail prematurely, create compatibility issues, and could even void your warranty. That small initial saving can quickly become a massive liability.

When you need a reliable partner for genuine parts and practical advice on your construction machinery maintenance challenges, you can trust the team at Wilco Manufacturing. Give us a call to discuss your project needs and learn how our expertise can support your success. Learn more at https://wilcomfg.com.