A heavy equipment maintenance schedule is a detailed plan for servicing your machinery. It outlines routine inspections, fluid changes, and component replacements required to keep your assets operating at peak performance. The primary goal is to prevent failures before they happen, shifting from a reactive "fix it when it breaks" model to a proactive strategy. This approach enhances equipment reliability, extends its operational life, and, most importantly, prevents expensive, unplanned downtime that can derail a project.

Why Your Maintenance Schedule Is a Profit Center

It’s time to stop thinking about equipment upkeep as just another operational cost. A heavy equipment maintenance schedule isn't a chore. it’s a powerful tool that directly boosts your company’s bottom line and provides a competitive advantage. When you move from a reactive mindset to a culture of proactive care, you’re not just servicing machines, you're protecting valuable assets, keeping projects on schedule, and making your worksite safer for everyone.

This shift is even more critical for specialized gear working in tough environments. Consider an amphibious excavator clearing a pipeline route through a corrosive saltwater marsh. It faces challenges a standard machine on a dry construction site never will. Without a disciplined maintenance schedule, the risk of hydraulic failure, pontoon damage, or premature wear on critical parts skyrockets.

Protecting Assets and Ensuring Reliability

Every piece of heavy equipment is a massive capital investment. A proactive maintenance plan is the best insurance policy you can have against premature depreciation and catastrophic failure. By catching and addressing small issues before they snowball, you prevent minor annoyances from becoming budget-destroying repairs. This disciplined approach is what builds true operational reliability, the foundation of any successful project.

At Wilco Manufacturing, this principle is at the core of everything we do. We know our amphibious excavators and hydraulic undercarriages are pushed to the limit in the world's most demanding environments, from dredging projects to environmental cleanups. For us, meticulous maintenance isn't just a recommendation. it's fundamental to delivering the performance and reliability our clients depend on.

The Financial Impact of Proactive Maintenance

The numbers don't lie. The global market for construction equipment maintenance is a multi-billion dollar industry for good reason. Companies that adopt data-driven service schedules see real, measurable gains in efficiency. Planned inspections and regular fluid analysis make a significant difference.

Modern digital asset management platforms now allow managers to track operating hours and schedule service just before a potential failure point is reached. This directly slashes repair costs and keeps equipment on the job site earning revenue.

A well-executed maintenance schedule does more than just prevent breakdowns. It turns a major, unpredictable cost center into a predictable, manageable expense, which leads to better cash flow and more accurate project bidding.

Knowing how to manage your assets, people, and budget is the key to getting the best return on your maintenance efforts. To get the most out of your program, it helps to learn how to optimize resource allocation and ensure every dollar spent on maintenance delivers a clear financial benefit. When you start treating maintenance as a profit driver, you build a much more resilient and successful operation.

Building Your Maintenance Framework

Putting together an effective heavy equipment maintenance schedule can feel like a huge undertaking, but it all boils down to a few foundational pieces. The real goal is to build a clear, actionable framework that actually works for your specific fleet and the unique environments it operates in. This isn't about downloading a generic checklist. it's about crafting a system that reflects your operational reality.

First, you need a complete inventory of your equipment. Document every machine, from your primary excavators to smaller support gear, and make sure to capture the make, model, year, and serial number. Once you have that list, your next job is to gather the original equipment manufacturer (OEM) manuals for each asset. Think of these manuals as your guide, they hold the factory-recommended service intervals and specs that will become the backbone of your schedule.

Finally, take an honest look at your typical operating conditions. This is where a one-size-fits-all approach completely falls apart. For instance, an amphibious excavator performing coastal restoration is constantly battling saltwater, sand, and other corrosive elements. Its maintenance plan must be far more rigorous than one for a standard excavator working on a dry, inland construction site.

Organizing Your Maintenance Tasks

With your inventory, OEM guidelines, and operational context in hand, you can start organizing the actual maintenance tasks into a master system. You could use anything from a detailed spreadsheet to specialized management software. The tool isn't as important as the principle behind it, which is categorization.

Group every single maintenance action by two key criteria: frequency and type. This simple structure is what turns a long, overwhelming list of duties into a logical, manageable workflow.

- By Frequency: This is the most intuitive way to organize. Group tasks into intervals like daily, weekly, monthly, or by operating hours, for instance, every 250, 500, or 1000 hours.

- By Type: Within each frequency, break tasks down further. Common categories include inspections (visual checks, system tests), lubrication (greasing pins, checking gearbox oil), and component replacement (filters, belts, seals).

This two-pronged approach ensures nothing falls through the cracks and makes it much easier to plan for parts inventory and technician schedules. To keep everyone on the same page, lean on clear documentation. Using a good Standard Operating Procedure template can make a world of difference in ensuring every task is performed consistently and correctly, no matter who is doing the work.

To give you a clearer picture, here’s how you might structure tasks for a specialized machine that sees heavy, wet use.

Sample Maintenance Task Frequency for Amphibious Excavators

| Frequency | Task Type | Example Action for Amphibious Excavator |

|---|---|---|

| Daily/Pre-Op | Inspection | Check pontoon integrity and look for signs of water intrusion. |

| Weekly/50 Hours | Lubrication | Grease all pivot points, paying extra attention to seals exposed to water. |

| Monthly/250 Hours | Inspection | Inspect hydraulic propulsion system hoses and connections for leaks or wear. |

| Quarterly/500 Hours | Component Check | Test bilge pumps and clean intake screens to ensure proper function. |

| Annually/1000 Hours | Major Service | Drain and inspect pontoon compartments; service hydraulic track motors. |

This table illustrates how the operating environment directly influences the maintenance schedule, requiring more frequent and specific checks compared to standard equipment.

Adapting for Specialized and Aging Equipment

The need for a solid, adaptable framework is only growing. A major trend we're seeing is the aging of the global equipment fleet, which naturally means more maintenance. Fleets in construction, mining, and energy are getting older, and keeping that equipment running requires more frequent and complex service.

This reality means your maintenance framework can't be a "set it and forget it" document. It has to be a living system that you review and adjust based on equipment age, performance data, and direct feedback from your operators.

For specialized machinery like our amphibious excavators, the framework must account for unique components that standard machines just don't have. The pontoons, hydraulic propulsion systems, and water-tight seals all have very specific service needs. Our team provides detailed guidance to ensure these critical systems get the attention they need to perform reliably in the harshest environments.

A well-designed framework, tailored to your specific fleet, is the blueprint for efficiency, reliability, and ultimately, profitability.

Actionable Checklists for Key Maintenance Intervals

A solid maintenance framework is your blueprint, but it’s the actionable checklists that get the job done. To move from theory to practice, you must break down your heavy equipment maintenance schedule into clear, repeatable tasks organized by critical service intervals. These checklists drive consistency and accountability, ensuring nothing gets missed, no matter which technician is on the job.

This becomes even more critical for specialized machines like amphibious excavators. Their checklists must account for unique components like pontoons and hydraulic propulsion systems and the harsh, wet environments they operate in. A generic list just won't cut it when you’re fighting the constant threat of water intrusion and corrosion.

The Daily Walk-Around Inspection

Think of the daily walk-around as your first line of defense against unplanned downtime. It’s a quick but absolutely essential pre-op check designed to catch obvious issues before they snowball into shift-ending failures. This routine needs to be second nature for every operator. It takes just a few minutes but can save you thousands in repair costs.

For an amphibious excavator working a dredging or pipeline project, this isn't just about the standard machine checks. It's a highly targeted assessment of its specialized systems.

Key Daily Checklist Items:

- Visual Fluid Scan: Before start-up, look for any drips or pooling under the machine. Hydraulic fluid, engine oil, or coolant leaks are telltale signs of trouble. A small drip found in the morning prevents a major failure and a potential environmental spill later in the day.

- Pontoon and Seal Integrity: Give the pontoons a thorough visual inspection for any dents, cracks, or other damage. Check the primary seals around moving parts for visible wear or debris that could compromise their effectiveness.

- Track and Undercarriage Check: Eyeball the track tension to make sure it’s within the OEM’s recommended specs. You're also looking for mud, rocks, or other debris packed into the undercarriage, which can dramatically accelerate wear on your rollers and track chains.

- Hydraulic Hoses and Connections: Do a quick scan of all visible hydraulic lines. Look for abrasions, bulges, or leaks, paying close attention to fittings and connection points where failures often start.

- Safety Equipment Functionality: A simple one, but vital. Confirm that lights, horns, backup alarms, and the cab’s protective structures are all in good working order.

The 250-Hour Service Interval

Hitting 250 operating hours is the first major milestone for most heavy equipment service schedules. At this point, you're moving beyond simple visual checks and getting your hands dirty with preventive maintenance. This service is all about changing out critical fluids and filters that have hit the end of their initial service life.

This is your best opportunity to flush out the contaminants that inevitably build up during break-in and operation, giving the machine's core systems a fresh start. For any equipment working in dusty land reclamation sites or muddy swamps, this interval is simply non-negotiable.

The 1000-Hour Major Inspection

The 1000-hour mark is a big deal. This is a comprehensive, deep-dive inspection of the machine’s structural and mechanical components to assess long-term wear and tear. It’s far more intensive than the 250-hour service, requires more time, and is designed to identify and replace parts that are getting close to the end of their lifecycle.

At this stage, you’re proactively replacing high-wear components instead of waiting for them to fail. This service is the cornerstone of extending the operational life of your asset and ensuring its reliability for the next thousand hours of demanding work.

Key 1000-Hour Service Tasks:

- Comprehensive Fluid Analysis: It's time to play detective. Take samples of the hydraulic fluid, engine oil, and coolant and send them to a lab. This analysis can reveal hidden issues like water contamination or microscopic metal particles, early warning signs of internal component wear that you can't see with the naked eye.

- Filter and Fluid Replacement: Replace all primary and secondary filters, including engine, hydraulic, fuel, and air. This is also when all major fluids are typically drained and replaced according to OEM specifications.

- High-Wear Component Inspection: Now you’re closely examining pins, bushings, and bearings for any excessive play or wear. On an amphibious unit, this includes a detailed inspection of the track propulsion motors and pontoon mounting hardware.

- Structural Integrity Check: Inspect the boom, stick, and frame for any signs of stress fractures or cracks. Pay extra close attention to weld points, as that’s where fatigue often shows up first.

Sourcing the right parts for these major services is critical. For genuine, reliable components that keep your machinery performing at its peak, you can find a complete inventory of Hydratrek parts to support all your maintenance needs.

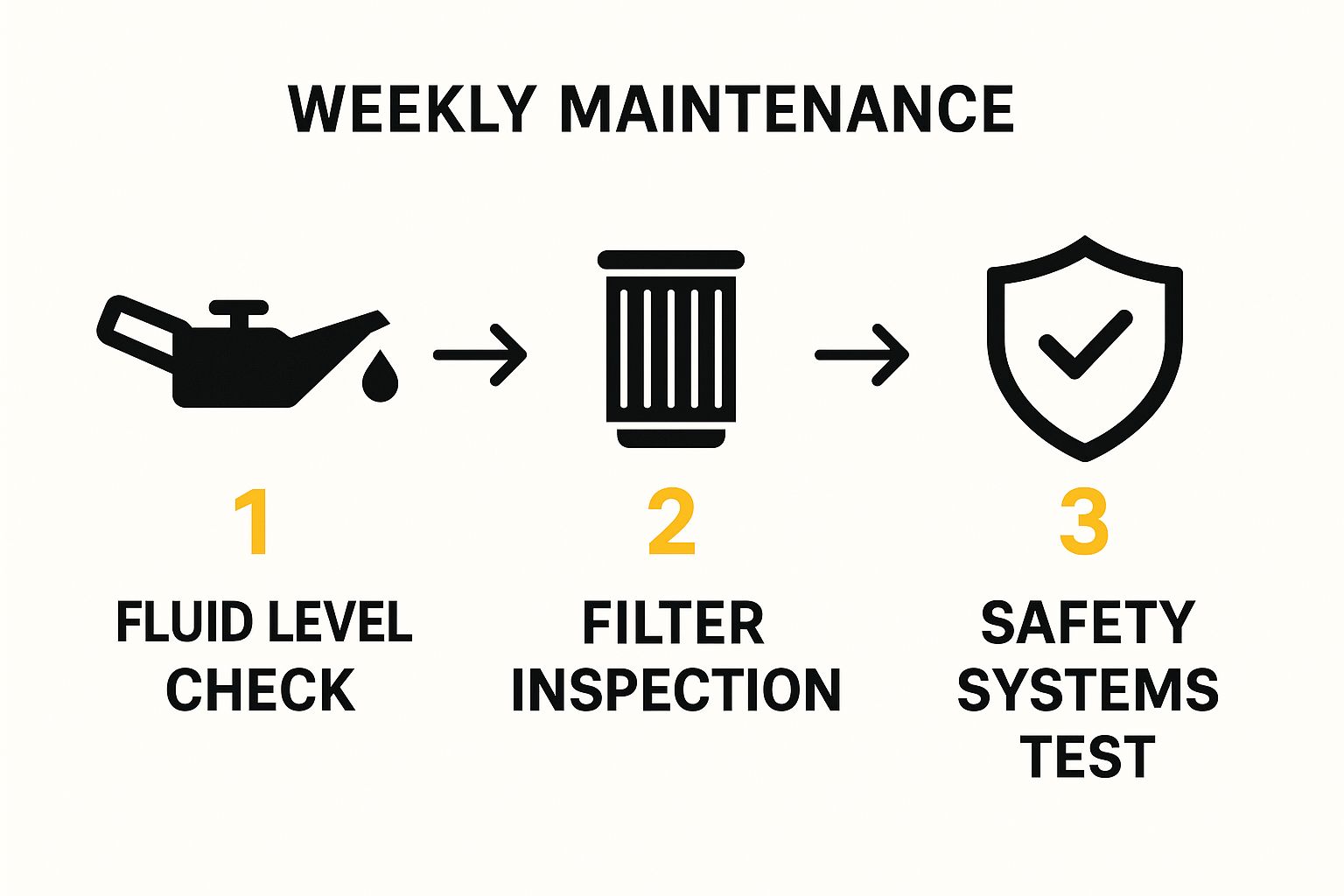

This graphic shows a simplified weekly maintenance workflow that builds upon these daily checks.

This visual flow highlights how consistent, sequential checks on fluids, filters, and safety systems form the foundation of a reliable weekly maintenance routine.

Using Technology for Smarter Maintenance

Paper logs and manual checklists just don't cut it anymore. They’re slow, prone to error, and a headache to manage. A truly modern heavy equipment maintenance schedule runs on technology built to automate mundane tasks, deliver real-time data, and flag problems before they shut a job site down. This isn't just about adopting new technology. it's a strategic move to stay competitive.

By embracing the right tools, you shift from a reactive "fix-it-when-it-breaks" model to a proactive, data-informed strategy. It’s about optimizing every part of your maintenance program, from scheduling technicians to managing parts, so your machines are always ready to work.

The Power of Telematics Data

At the core of this approach is telematics. Think of these systems, often factory-installed on equipment like excavators or dozers, as the central nervous system of your fleet. They constantly send a stream of operational data back to your office, giving you a level of insight that was unthinkable just a decade ago.

This is so much more than just a dot on a map. Telematics captures the critical metrics that are the lifeblood of a proactive maintenance plan:

- Engine Hours: No more guesstimates. You get precise, automatic logging of operating hours, making sure crucial service intervals are never missed.

- Fuel Consumption: Keep an eye on fuel burn to spot inefficiencies. A sudden spike can be the first sign of an underlying engine or hydraulic problem.

- Idle Time: See exactly how long a machine is running without actually working. This helps you cut down on wasted fuel and unnecessary engine wear.

- Fault Codes: Get diagnostic trouble codes sent directly from the machine's computer. Your technicians can know what’s wrong before they even grab their toolbox.

Imagine an excavator hitting its 500-hour service mark. A good telematics system can automatically trigger a work order in your management software. This type of automation prevents the small oversights that often lead to catastrophic failures down the road.

Centralizing Operations with CMMS

All that valuable data from telematics needs a place to go where it can be put to work. That’s the job of a Computerized Maintenance Management System (CMMS). A CMMS is the command center for your entire maintenance operation, transforming raw numbers into clear, actionable intelligence.

This software helps you manage every aspect of your maintenance workflow. You can schedule technicians, track work orders from start to finish, and manage your parts inventory so you aren't waiting on a filter to get a machine back online. Most importantly, it creates a digital service history for every piece of equipment you own. This detailed log is invaluable for diagnosing recurring problems, proving compliance, and getting the best possible price when it’s time to sell.

A well-implemented CMMS turns your maintenance data from a simple record into a strategic asset. It gives you the clarity to make tough repair-versus-replace decisions and justify your budget with hard numbers.

This isn't a niche market. The global heavy equipment maintenance industry was valued at roughly USD 79.66 billion in 2024 and is on track to hit USD 122.81 billion by 2033. This growth is fueled by technologies like telematics that empower fleet managers to track equipment health in real time and lower their total cost of ownership. While there's an upfront investment, the long-term savings are undeniable. You can dive deeper into these market trends over at VerifiedMarketReports.com.

Moving Toward Predictive Analytics

The ultimate goal here is to evolve from just preventing failures to actually predicting them. This is the promise of predictive analytics. By feeding historical data from telematics and your CMMS into advanced algorithms, you can start to identify the subtle patterns that come before a major component fails.

Instead of swapping a hydraulic pump every 2,000 hours just to be safe, a predictive system might alert you that a specific machine’s pump is showing early signs of failure at 1,850 hours, based on tiny fluctuations in pressure and temperature. This lets you step in at the perfect time, preventing a messy and expensive on-site failure while still getting the most life out of the part.

This kind of foresight is particularly vital for specialized machinery, like Wilco’s powerful amphibious dozers, which are often put to work in tough, remote environments where unplanned downtime simply isn't an option.

Putting the Plan to Work and Measuring What Matters

A maintenance plan on paper is just that, paper. The real test happens out in the field, where dirt, grease, and deadlines collide. This is where your strategy becomes reality, and its success hinges on the people and processes you've put in place.

It starts with your team on the ground. Your operators are your first line of defense against costly downtime. They're in the cab day in and day out, so they're the first to feel a subtle change in hydraulic pressure, hear a new engine knock, or notice a slight drift in the controls. If you build a culture where they feel empowered to report small issues immediately, without fear of slowing things down, you'll catch minor problems before they snowball into catastrophic failures.

This culture needs to be backed up by clear communication and solid training. Everyone, from the newest operator to the seasoned mechanic, needs to know their exact role. That means training them on how to log their findings correctly, submit work orders through your system, and stick to the standardized procedures for routine checks. Consistency is what turns a good plan into a bulletproof operational system.

Tracking Performance with Key Metrics

So, how do you actually know if your maintenance program is making a difference? You have to measure it. Tracking the right key performance indicators (KPIs) gives you the hard data to prove your program's value, spot trends before they become problems, and justify your budget. To really get a handle on whether your heavy equipment maintenance schedule is a profit driver or a cost center, you need a constant focus on measuring operational efficiency.

When you monitor these metrics, maintenance stops being just another expense and becomes a strategic part of the operation. You can have data-driven conversations about asset health instead of relying on gut feelings.

Important KPIs for Your Maintenance Schedule

Here are a few of the most critical KPIs you should be tracking to gauge the health of your fleet and the real-world impact of your maintenance schedule:

- Equipment Availability Rate: This is simply the percentage of time a machine is ready to work when you need it. A consistently high availability rate, for example, 90% or more, is a clear sign your preventive maintenance is working and keeping surprises at bay.

- Mean Time Between Failures (MTBF): MTBF tells you the average amount of time a piece of equipment runs between one breakdown and the next. Your goal is to see this number climb steadily. A rising MTBF is proof that your proactive work is extending the life of your machines.

- Maintenance Cost Per Operating Hour: This one is straightforward. calculate the total cost of maintenance (parts, labor, fluids) and divide it by the total hours the machine has run. Keeping an eye on this metric helps you pinpoint which assets are becoming money pits, making those tough repair-versus-replace decisions much easier.

By diligently tracking these KPIs, you create a powerful feedback loop. The data shows you what's working and what isn't, allowing you to fine-tune service intervals, adjust your parts inventory, and better schedule your technicians' time for maximum impact.

This table gives a quick breakdown of these essential KPIs and why they're so important for your bottom line.

Key Maintenance KPIs and Their Impact

A good maintenance program isn't just about fixing things. it's about seeing the big picture. These key performance indicators give you the data you need to connect your team's hard work in the shop directly to success on the job site.

| KPI (Key Performance Indicator) | What It Measures | Why It Matters for Your Projects |

|---|---|---|

| Equipment Availability | The percentage of time equipment is ready to work. | Directly impacts project timelines by ensuring machines are available to meet critical path deadlines. |

| Mean Time Between Failures | The average time a machine operates before a breakdown. | A longer MTBF means fewer interruptions, leading to more predictable and reliable project execution. |

| Maintenance Cost Per Hour | The total cost of upkeep divided by operational hours. | Helps control project budgets by identifying costly assets and preventing unexpected repair expenses. |

Ultimately, tracking these numbers transforms your maintenance department from a reactive repair crew into a proactive force that drives profitability and project success.

At Wilco Manufacturing, our commitment goes beyond just building world-class amphibious equipment. We provide meticulously maintained machinery, backed by the expertise to help our clients succeed in the toughest environments on earth. Our own strict maintenance protocols are our guarantee that when a Wilco excavator lands on your site, it’s ready to perform safely and reliably, protecting both your timeline and your budget.

Frequently Asked Questions

When it comes to maintaining heavy equipment, especially specialized machines working in tough environments like dredging, construction, and environmental remediation, we get a lot of questions. Here are a few of the most common ones we hear from fleet managers and operators.

How Do I Adapt a Standard Maintenance Schedule for Amphibious Equipment?

You can't just take a maintenance checklist for a land-based machine and apply it to amphibious equipment. The game changes completely when you're dealing with constant exposure to water, mud, and corrosive elements.

The first step is to drastically increase the frequency of inspections for pontoons, seals, and hydraulic propulsion systems. We're talking daily, high-pressure wash-downs to remove saltwater, sand, and grit. This is non-negotiable. It not only fights off long-term corrosion but also gives your team a clean surface for a proper visual check.

Beyond that, you have to adjust your service intervals for key components:

- Lubrication: Any moving parts near the waterline, like pins and bushings, need grease far more often. The goal is to constantly purge contaminants before they can work their way in.

- Fluid Analysis: Pulling hydraulic fluid and oil samples must happen more frequently. You're looking for early signs of water contamination, which will damage a hydraulic system faster than almost anything else.

- Pontoon Integrity: Your schedule needs dedicated checks for the pontoons themselves. This means regular pressure tests and detailed visual inspections for any cracks, leaks, or damage that you'd never find on a standard excavator's checklist.

What Is the Biggest Mistake Companies Make with Maintenance Schedules?

By far, the single biggest and most expensive mistake we see is inconsistency. A company will invest time and money into creating a brilliant, detailed plan, only to let it fall by the wayside. A less-perfect plan that you follow 100% of the time is infinitely better than a perfect plan you ignore when things get busy.

This almost always happens when a project deadline is looming. The pressure mounts, and the decision is made to skip or push back a scheduled service to keep a machine running "just a little longer." It's a classic case of prioritizing short-term production over long-term preservation. This gamble rarely pays off and usually results in catastrophic failures, sky-high repair bills, and far more unplanned downtime than the original service would have caused.

A successful maintenance program isn't just a document; it's a culture. Scheduled upkeep has to be treated as a non-negotiable part of the operation, just like daily safety protocols.

Think of your schedule as a commitment to the health and profitability of your most valuable assets. The moment you start making exceptions, the whole system starts to crumble.

How Does a Good Maintenance Schedule Reduce My Total Cost of Ownership?

A well-run maintenance schedule is one of the most powerful tools you have for lowering your Total Cost of Ownership (TCO). It's not an expense. it's a strategic investment that pays off in several tangible ways.

First, preventive maintenance is always cheaper than emergency repairs. You avoid the premium costs of rush-ordered parts, overtime for mechanics, and the logistical nightmare of a breakdown in the middle of a job site.

Second, it keeps your machines working, and uptime is where you make your money. A machine that's available is a machine that's generating revenue. For more on this, you can explore the latest trends and news in heavy equipment operations. You can learn more about industry news on our blog.

Third, equipment that's properly cared for simply runs better. It burns fuel more efficiently and delivers the power you need, which lowers daily operating costs and boosts productivity.

Finally, a detailed and consistent service history extends the life of your machinery. This pushes back the massive capital expense of buying a replacement and significantly increases the equipment's resale value when you do decide to upgrade your fleet. Every scheduled oil change and inspection is an investment that prevents a much larger, unplanned expense down the road.

A well-executed maintenance program is the backbone of any successful operation, ensuring your equipment is ready for the demands of the job. At Wilco Manufacturing, we provide reliable, impeccably maintained amphibious equipment and the expert support to help your projects succeed. For a partner that understands the true value of operational readiness, contact us today. Learn more about our solutions at Wilco Manufacturing.