When your project site turns into a swamp, standard equipment is dead in the water, sometimes literally. This is precisely where renting an amphibious excavator makes a world of difference, giving you specialized power without the hefty price tag of a purchase. For project managers, it’s about getting the right tool for the job, right when you need it, especially when that job involves wetlands, shorelines, or straight-up waterways.

This guide was created to make your rental decision an easy one. We will walk you through why renting often makes more sense than buying for specialized machines, how to match the right excavator to your project’s unique terrain, and the ins and outs of the rental process, so everything goes off without a hitch.

Your Guide to Amphibious Excavator Rentals

A conventional excavator is going to sink in saturated soil or a marsh. Projects in these kinds of tricky environments don't just need equipment that can survive; they need machines built to excel. An amphibious excavator is engineered to do just that, floating and navigating on terrain that would swallow other heavy machinery. For many project managers, renting this specialized gear is a smart financial and logistical move.

Why tie up a massive amount of capital in a machine you might only need for one specific phase of a job? Renting keeps you agile. If you want to dive deeper into the general pros and cons of renting versus buying, this comprehensive guide to construction equipment hire is a great resource.

Getting to Know the Machine

So, what makes an amphibious excavator work? Think of it as a hybrid. It has the powerful digging arm and cab of a standard excavator, but it sits on a completely different undercarriage.

Instead of typical tracks, it's mounted on large, sealed pontoons that are buoyant enough to float. These pontoons are fitted with heavy-duty tracks, giving the machine the ability to crawl on solid ground, push through soft mud, and paddle through water. It’s a remarkable piece of engineering.

You can get a better sense of this unique design by checking out the specifics of a high-quality amphibious excavator to see it in action. Working with a seasoned expert like Wilco Manufacturing means you’re not just getting a machine; you’re getting the experience needed to turn a logistical nightmare into a successful project.

Why Renting Is Often Smarter Than Buying

Making the call between renting and buying an amphibious excavator is a major decision for any project manager. While owning your own machine might have some appeal, the massive initial cost, relentless maintenance demands, and logistical headaches make renting the smarter business move for most jobs.

Renting frees up your capital and your team's time. Instead of getting bogged down in asset management, you can pour all your energy into what you do best: executing the project.

This approach is a lifesaver for companies with specialized or fluctuating workloads. It just doesn't make sense to have millions tied up in a machine that's collecting dust between projects. Renting lets you grab the exact machine you need, right when you need it, ensuring you’re not paying for idle iron.

Keep Your Operational Budget in Check

When you rent amphibious equipment, your costs become predictable and easy to manage. That massive capital investment disappears, replaced by a straightforward operational expense that you can plug directly into your project budget. This move sidesteps all the hidden costs that come with ownership.

Those hidden costs add up fast:

- Maintenance and Repairs: These machines work in some of the toughest conditions imaginable. That means specialized, and often expensive, upkeep is not a suggestion, it's a necessity.

- Storage and Security: You can't just park an amphibious excavator in the back lot. It needs a secure, suitable place when it's not working.

- Transportation Logistics: Getting one of these giants to and from a job site is a major operation in itself, requiring special permits and transport.

When you get your amphibious excavators for rent, those headaches belong to someone else. A good rental partner like Wilco Manufacturing takes care of the maintenance, the storage, and the transport. Your crew can just show up and get to work.

Stay Flexible and Use the Best-Available Technology

The world of heavy machinery never stands still. New models are always coming out with better fuel efficiency, more power, and smarter features. Renting gives you access to the latest and greatest without locking you into a machine that will eventually become outdated. That kind of flexibility is a real competitive edge.

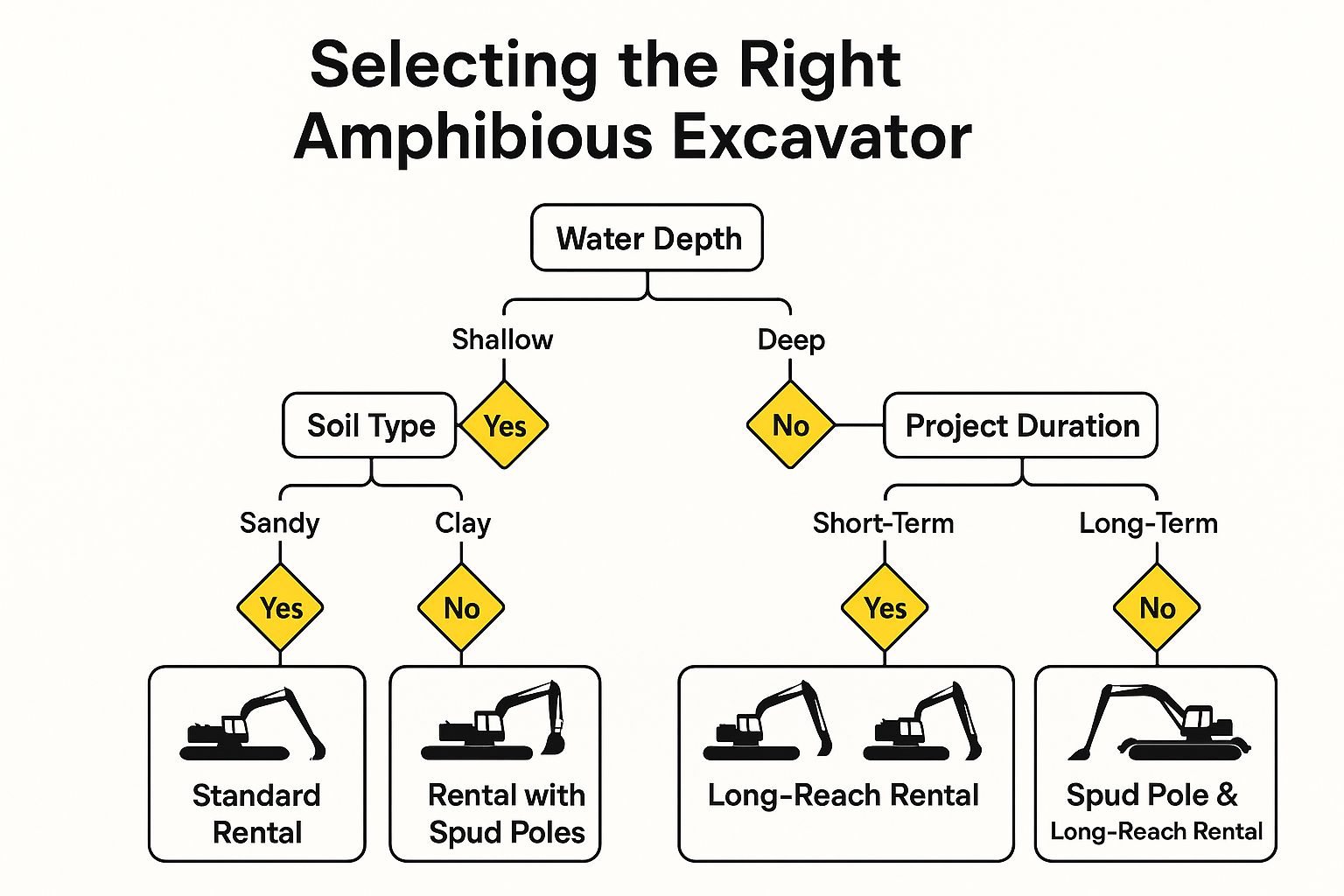

This decision tree helps visualize how to pick the perfect rental setup based on your site's unique challenges.

As you can see, matching the machine's capabilities to specific factors like water depth and soil conditions is absolutely essential for getting the job done right.

Renting transforms a major capital expenditure into a controlled operational cost, preserving your borrowing power and improving cash flow. This financial agility is crucial for navigating the unpredictable nature of large-scale construction and environmental projects.

To help clarify the trade-offs, here’s a look at how renting and buying stack up against each other.

Rental vs Purchase Decision Factors

| Factor | Renting | Purchasing |

|---|---|---|

| Upfront Cost | Low, typically a deposit and first rental period payment. | Extremely high, a major capital expenditure. |

| Maintenance | Included in the rental agreement; handled by the provider. | Owner's responsibility; can be costly and complex. |

| Technology | Access to the latest models and features. | Locked into the purchased model until replacement. |

| Utilization | Pay only for the time the machine is needed. | Costs accrue even when the machine is idle. |

| Flexibility | Easily switch machines to match specific job needs. | Limited to the capabilities of the owned machine. |

| Logistics | Transportation and storage are often managed by the rental company. | Owner must arrange and pay for transport and storage. |

Ultimately, the choice depends on your company's long-term strategy and workload. For most, however, the financial and operational freedom of renting is hard to beat. The high price tag and complex upkeep of these machines have pushed more companies toward renting. This model provides a cost-effective solution with flexible terms, allowing project managers to scale their equipment up or down without a huge financial commitment. It minimizes risk and ensures you're always working with modern, reliable equipment. You can dive deeper into these industry shifts by exploring the full research on the amphibious excavator market.

Solving Problems in Challenging Terrains

Where the solid ground gives way to water, traditional heavy machinery simply stops. For an amphibious excavator, that’s where the real work begins. These aren’t just machines built to survive in tough environments; they’re designed to master them, completely changing how project managers can tackle complex job sites. What was once an inaccessible swamp becomes a manageable work zone.

The magic is in the design. Instead of standard tracks, these excavators sit on buoyant, sealed pontoons with wide treads. This setup distributes the machine's massive weight so well that its ground pressure is often less than a human footprint. Think about that, a multi-ton machine can crawl across saturated mud and swampland without sinking, all while minimizing environmental damage.

This unique ability makes them the go-to solution for critical jobs where standard equipment would be hopelessly bogged down.

Waterway Dredging and Maintenance

Keeping our waterways clear is crucial for everything from commerce to flood prevention. Over time, silt, sand, and debris build up in rivers and harbors, making them shallow and obstructing water flow. An amphibious excavator gets right in the water to solve the problem directly.

- Channel Deepening: They scoop out sediment to maintain the necessary depths for boat and barge traffic.

- Debris Removal: After a big storm, these machines are perfect for pulling out fallen trees and other junk blocking a river.

- Levee Reinforcement: They can easily get to and shore up levees from the waterside, a job that’s next to impossible for land-based equipment.

Shoreline Restoration and Erosion Control

Erosion is a constant battle along coasts and lakesides, threatening property and natural habitats. Amphibious excavators are the ideal tool for shoreline restoration, giving you precision and power right at the water's edge. Because they can work in shallow water, they can place riprap, build seawalls, and install other protective barriers without the need for cumbersome barges or temporary roads.

When you're dealing with such unpredictable environments, having solid operational risk assessment templates is key to keeping the project safe and on track.

Environmental Cleanup and Remediation

Cleaning up contaminated wetlands requires a delicate touch. You need to get the job done without causing more harm. The incredibly low ground pressure of an amphibious excavator means sensitive ecosystems are disturbed as little as possible.

By operating directly in marshes and swamps, these machines can remove contaminated soil, clear out invasive plants, and help restore habitats with surgical precision. This light-footed approach is exactly why renting one is such a smart move for environmentally sensitive projects.

Pipeline Installation in Swamps

Trying to lay a pipeline through a swamp is a logistical nightmare. The ground is too soft for regular machines, and the area is often environmentally protected. Amphibious excavators cut through these challenges by creating their own stable work platform on the most unstable ground.

They can clear the path, dig the trench, and support the pipe-laying crews in terrain that would otherwise demand expensive, disruptive access roads. Renting an amphibious excavator isn't just getting a piece of equipment; it's getting a powerful, adaptable solution for the planet's toughest jobs.

Choosing the Right Excavator for the Job

Picking the right amphibious excavator isn’t just another item on the project checklist. It's a make-or-break decision that can directly influence your budget and timeline. The wrong machine will bog you down, literally, leading to costly delays and operational headaches. Think of this as your practical playbook for getting it right the first time.

The key is to start not with the machine, but with the ground beneath it. A deep understanding of your job site is the single most important piece of the puzzle. Before you even think about engine specs or boom length, you need a crystal-clear picture of the terrain you're up against.

Evaluate Your Job Site Conditions

No two wetlands, shorelines, or riverbeds are the same. Each has its own unique personality, and respecting those differences is the first step in selecting the right equipment from the available amphibious excavators for rent.

To get started, you need to answer a few critical questions about your work environment:

- How deep is the water? This isn't just a simple measurement. Deeper water might mean you need supplementary pontoons or even spud anchors to keep the machine stable and safe.

- What’s the ground like under the water? Is it soft silt, thick clay, or a sandy bottom? Each of these materials interacts differently with the excavator's undercarriage, heavily influencing the pontoon design and track type you’ll need.

- What kind of vegetation are you dealing with? Dense reeds, tangled roots, or submerged logs can stop a project cold. You may need specialized attachments like a vegetation cutter just to clear a path for the main work to begin.

Answering these questions gives you a detailed profile of your worksite. It’s what transforms a generic call for an excavator into a specific, actionable equipment plan when you talk to a rental partner. To learn more about how different machines handle various environments, our guide on the versatility of marsh buggies beyond wetlands is a great resource.

Match Technical Specifications to Your Project

With a solid understanding of your site, you can now start looking at the hardware. This is where you connect the dots, matching the machine’s capabilities directly to the demands of the job. It's tempting to go for the biggest, most powerful excavator available, but that’s often a mistake. Precision and suitability trump raw power every time.

Focus on these key specifications:

- Machine Size and Weight: This is all about ground pressure. A lighter, well-distributed machine is essential for protecting sensitive ecosystems and, more importantly, for preventing the excavator from sinking.

- Engine Power: The engine needs enough muscle to operate the excavator and any power-hungry hydraulic attachments simultaneously without sputtering or losing performance.

- Boom and Arm Length: Your required reach is a huge factor. Dredging a channel or restoring a shoreline often calls for a long-reach configuration, which isn't standard on every model.

- Pontoon Design: The size, shape, and design of the pontoons determine the machine’s buoyancy and stability. They must be correctly matched to the water depth and soil conditions you identified earlier.

The demand for these machines is exploding for a reason. They are absolutely vital for modern environmental and infrastructure work. In fact, the global amphibious excavator market is projected to skyrocket from USD 8.75 billion in 2025 to a massive USD 19.35 billion by 2032. This growth is a testament to their value in projects all over the world.

Choosing the right equipment isn't about finding a machine that can simply do the job. It's about finding the one that can do it most efficiently, safely, and cost-effectively. A thorough site assessment is the foundation of that decision.

Navigating the Rental Process with an Expert

Renting a specialized piece of equipment like an amphibious excavator shouldn't be a shot in the dark. When you work with a genuine expert, the whole process unfolds as a clear, predictable series of steps. It’s less of a simple transaction and more of a partnership, one focused on getting the right machine for your specific challenge.

It all starts with a conversation, not a catalog. A true equipment partner wants to understand the lay of the land, literally. They'll ask about your job site, the soil conditions, water depth, and the ultimate goal of the project. This initial talk is the foundation for everything, making sure the solution they propose is the one you actually need.

From Consultation to Mobilization

After they have a solid grasp of your project, the next step is a detailed and totally transparent quote. A professional quote for amphibious excavators for rent won't have any hidden corners; it will break everything down for you.

You should expect to see:

- The exact excavator model and any attachments you'll need.

- A clear breakdown of rental rates, be it daily, weekly, or monthly.

- All costs for transport, on-site assembly, and takedown at the end.

- A clear outline of who handles fuel, routine maintenance, and operators.

This level of detail means no nasty surprises, allowing you to budget with confidence. Once the quote is accepted, you'll move on to the rental agreement. Before signing anything, it’s always smart to review the rental and hire terms and conditions to be sure you understand all your responsibilities. A good partner makes this document straightforward and fair, covering everything from insurance to maintenance.

A well-managed rental process is the signature of a reliable equipment partner. It shows they're committed not just to dropping off a machine, but to making sure your project runs smoothly from start to finish.

On-Site Support and Project Completion

The job isn't done once the paperwork is signed. Logistics are a huge piece of the puzzle, and an experienced provider like Wilco Manufacturing handles this part seamlessly. Moving an amphibious excavator isn't simple; it involves disassembly, trucking, and then careful reassembly on-site by technicians who know what they're doing.

When the machine arrives, the support continues. This might involve training your crew to operate the excavator safely and get the most out of it. Throughout your rental period, you should have access to reliable maintenance and tech support to keep downtime to an absolute minimum and your project moving forward. This complete approach turns a simple equipment rental into a fully supported partnership, giving you the peace of mind to focus on getting the job done.

It's More Than a Machine, It's a Partnership

Picking the right amphibious excavator is a huge part of the equation, but it’s only the beginning. The real key to seeing your project through to a successful finish is the people you partner with.

Any company can drop off a piece of equipment. A true partner, however, brings a whole other level of value. They deliver a complete solution, one built on years of hands-on experience and a genuine commitment to supporting your work. This is how a simple rental becomes a serious strategic advantage.

Renting an amphibious excavator has obvious perks, like freeing up capital and getting your hands on the latest models without the ownership headaches. But the real game-changer is when your rental provider becomes an extension of your own crew. They’re not just a voice on the phone; they’re your go-to experts.

They're Invested in Your Success

This means they’ll do more than just deliver the excavator. A great partner provides:

- Expert consultation to perfectly match the machine to your specific terrain and job requirements.

- Smooth, headache-free logistics to get the equipment to your site on time.

- Reliable on-site support to make sure any hiccup is dealt with fast, keeping downtime to an absolute minimum.

A partner who truly gets it knows what’s on the line with your project, whether you're laying pipeline, restoring a sensitive wetland, or reclaiming land. They've seen it all before and can offer insights that help you sidestep potential problems and get the most out of the machine from the moment it arrives.

Think of it this way: your project's success isn't just about the excavator's horsepower or reach. It's about having an experienced team in your corner, dedicated to making sure your amphibious excavator rental delivers exactly what you need to stay on track and on budget.

When you're ready to stop just renting equipment and start building a partnership, we’re here to help. Contact Wilco Manufacturing to talk about how the right amphibious solution, and the right team, can help you conquer your toughest challenges.

Your Questions, Answered

When you're looking at renting a piece of specialty equipment like an amphibious excavator, you're bound to have questions. It's a big decision, and getting the details right is key to keeping your project on time and on budget. Here are some of the most common questions we get from project managers.

What Goes Into the Rental Price?

The final number on a rental quote isn't pulled out of thin air. It’s a combination of a few key things: the specific size and model of the excavator, how long you'll need it (the rental duration), the logistics of getting it to your job site, and any special tools you need, like dredging pumps or long-reach arms. A good quote will break all of this down so you can see exactly where your money is going.

Do I Get an Operator with the Machine?

It really depends on what you need. We offer flexible arrangements. If you have your own crew with certified operators who know their way around this kind of machinery, that's perfectly fine. But if you need an expert, we can absolutely provide a highly experienced and certified operator to make sure the job gets done safely and efficiently.

The real power of these machines shines in emergency situations. During hurricanes and floods, they're often the first ones in, clearing debris and reopening crucial drainage channels. This not only speeds up recovery but makes the entire effort safer for everyone involved.

This unique capability is a major reason why demand for amphibious excavators is on the rise worldwide. You can dig deeper into their growing importance in environmental and disaster relief efforts to see the full picture.

How Do You Get Such a Big Machine to a Remote Site?

Getting an amphibious excavator to a hard-to-reach location is a carefully planned operation. We don't just put it on one big truck. The machine is broken down into its main parts, the pontoons and the upper excavator body.

These components are then loaded onto separate trucks and transported to your site. Once there, our technicians put it all back together, run a full series of checks, and make sure it's 100% ready for work before we hand you the keys.

Ready to bring in the right equipment for your most challenging project? The team at Wilco Manufacturing has the expertise and the machinery to match. Let's talk about what you're trying to build, visit us at https://wilcomfg.com to get the conversation started.