A rotating grapple excavator is a game-changer on the job site, essentially giving a standard excavator the dexterity and precision of a human hand. This powerful attachment combines strong jaws for gripping with a hydraulic rotator for 360-degree movement, turning a digging machine into a sophisticated material handling tool. For decision-makers in demanding industries like construction, demolition, and environmental cleanup, understanding this attachment's capabilities is key to unlocking new levels of project efficiency.

The Anatomy of a Rotating Grapple Excavator

Instead of thinking of it as a separate machine, it is better to view a rotating grapple as an advanced attachment that completely redefines what an excavator can do. It transforms a piece of heavy equipment into a multi-functional workhorse built for sorting, placing, and handling materials with incredible accuracy. This is especially crucial in complex environments like demolition or environmental cleanup, where precision is not just a bonus, it is essential.

The industry has certainly taken notice. The global market for excavator grapples was valued at an estimated USD 1.8 billion in 2023 and is projected to climb to roughly USD 3.2 billion by 2032. This explosive growth is fueled by a surge in infrastructure projects and a worldwide focus on more effective waste management. You can find more insights on this market growth on Dataintelo.

Core Components and How They Work

At its heart, the system is a marriage of two key components working in perfect sync. You have the powerful, hydraulically controlled jaws, often called shells or tines, that clamp down to securely grip anything from massive logs to loose debris. Then you have the hydraulic rotator, the component that provides that smooth, continuous 360-degree spin.

This combination is the secret to its effectiveness. An operator can pick up a load, rotate it to the exact angle needed, and place it precisely, all without constantly repositioning the entire excavator. It is a massive boost to efficiency, dramatically cutting down on cycle times and saving fuel in the process.

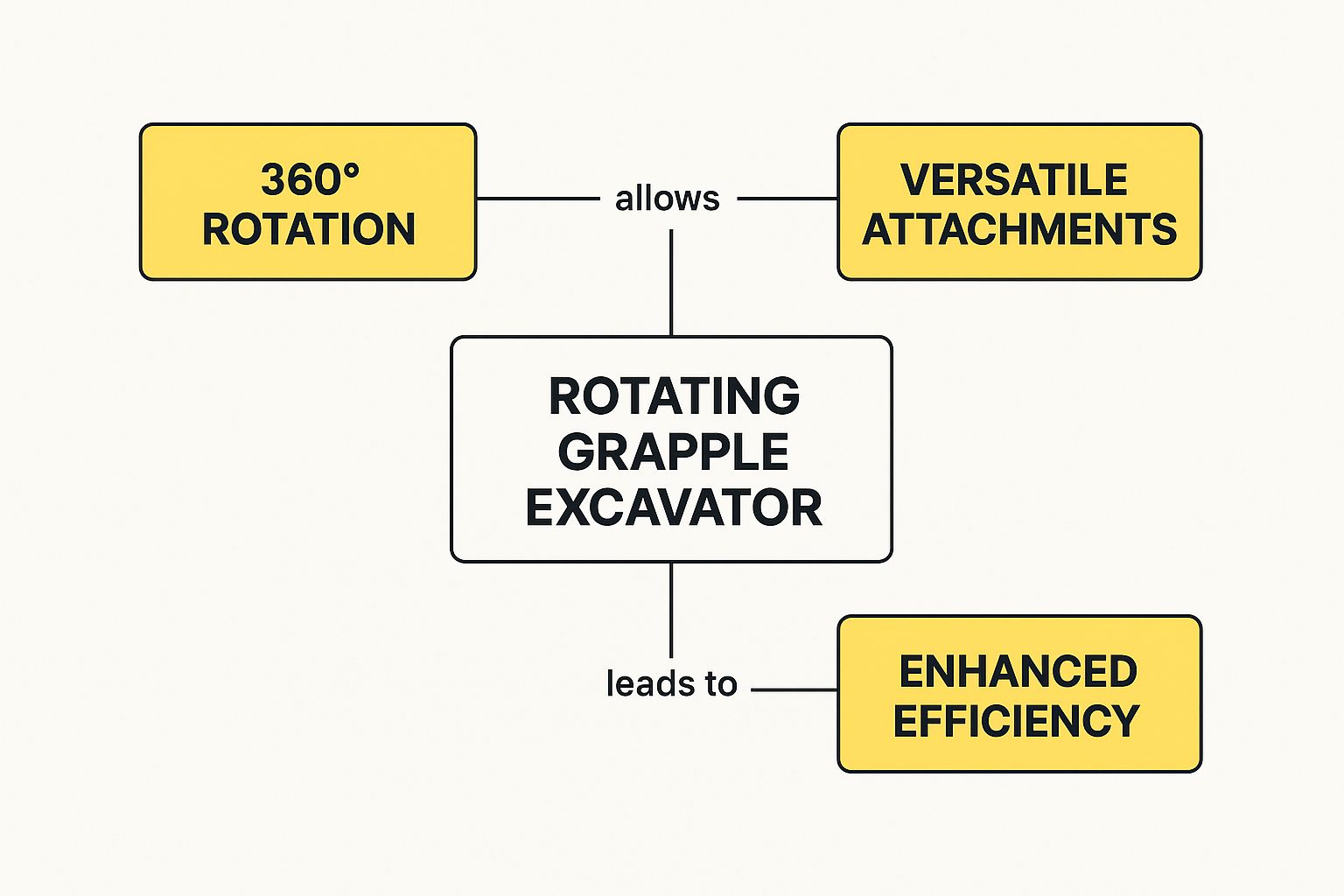

This image really drives home how these core concepts come together to make this attachment so powerful.

As you can see, the freedom to rotate combined with versatile gripping power directly translates to getting more work done, faster and smarter, on any site.

Let's break down the essential features that define a quality rotating grapple and the real-world benefits they provide.

Key Features of a Rotating Grapple

| Feature | Primary Benefit |

|---|---|

| 360-Degree Rotation | Allows for precise material placement without repositioning the excavator, boosting efficiency. |

| Hydraulic Jaws | Provide powerful and secure gripping force for a wide range of materials, from logs to scrap. |

| Durable Construction | Built with high-strength steel (like Hardox) to withstand the harsh demands of daily use. |

| Variable Jaw Types | Different jaw designs (e.g., bypass, clamshell) are available for specialized tasks. |

| Integrated Cylinder | Protects the hydraulic cylinder from damage, reducing downtime and maintenance costs. |

Ultimately, these features are not just technical specs. They are the ingredients that make this attachment such a valuable and versatile tool for so many different applications.

The Amphibious Advantage

When you mount a rotating grapple on an amphibious excavator, like the ones engineered by Wilco Manufacturing, its value skyrockets for tough projects in wetlands, swamps, and along shorelines. In these sensitive environments, the ability to work from a stable, floating platform while precisely handling materials is a true game-changer.

This setup allows operators to perform tasks that would otherwise be nearly impossible:

- Removing debris from waterways without disturbing the surrounding ecosystem.

- Placing riprap for shoreline restoration with surgical accuracy.

- Sorting materials during environmental remediation projects deep in marshlands.

This pairing of amphibious mobility with grapple dexterity empowers contractors to tackle jobs that conventional land-based equipment simply cannot reach. It is a perfect example of how specialized attachments create practical solutions for the industry’s most challenging problems.

Where These Tools Really Shine: Key Applications

The true test of any heavy equipment is not its spec sheet, it is how it performs on a real-world job site. This is where the rotating grapple excavator proves its worth. Its unique blend of raw power and fine-tuned precision makes it an essential piece of machinery in some of the toughest industries out there.

From the organized chaos of a city demolition to the delicate work of wetland restoration, this attachment consistently elevates both safety and productivity.

Construction and Demolition

In the high-stakes world of construction and demolition, time is money and precision is everything. A rotating grapple turns a standard excavator into a surgical instrument, allowing operators to dismantle structures with incredible control.

Instead of just smashing and grabbing, an operator can carefully pluck rebar from concrete, sort different materials into neat piles for recycling, and load trucks far more efficiently. This speeds up the entire demolition process and makes it easier to salvage and sell valuable materials. Of course, on any active site, safety is non-negotiable, which is why a solid plan and a practical guide to temporary fencing for construction sites are so important.

Forestry and Land Clearing

Out in the woods, crews need equipment that can handle heavy, unwieldy logs with both brute force and a gentle touch. This is exactly what a rotating grapple brings to the table. It is a game-changer for loading logs, stacking timber, and clearing away storm debris or underbrush.

The 360-degree rotation is the key. It lets an operator line up logs perfectly for loading without constantly having to move the entire excavator. On the uneven, often muddy ground of a forest, that is a massive advantage. It means less ground disturbance, less fuel burned, and less time wasted, making the whole operation more profitable.

Waste Management and Recycling

Sorting is the heart and soul of any material recovery facility or transfer station. Here, the rotating grapple is an absolute workhorse, tasked with separating valuable materials like metal, wood, and concrete from the general waste stream.

This is not just about moving trash around faster. This precise sorting directly feeds a more successful recycling program, diverting massive amounts of waste from landfills and helping create a circular economy.

An experienced operator can use the grapple to pick through huge, mixed piles with a level of accuracy a simple bucket could never achieve. This produces cleaner, higher-quality batches of recyclables, which is what makes these facilities economically viable.

Amphibious and Environmental Projects

Nowhere is the unique skill set of a rotating grapple more vital than in sensitive environmental work, especially when it is attached to the right machine. Mounted on a Wilco amphibious excavator, the grapple becomes a powerful instrument for environmental restoration. These specialized excavators can work in swamps, marshes, and along coastlines where conventional equipment would instantly get stuck.

This powerful combination is perfect for a range of critical tasks:

- Waterway Cleanup: Carefully pulling out fallen trees, invasive plants, and debris from rivers without churning up the riverbed or harming the surrounding habitat.

- Shoreline Restoration: Placing rocks and other erosion-control materials with precision to rebuild and protect natural coastlines.

- Environmental Remediation: Handling contaminated soil and other hazardous materials in fragile ecosystems with minimal disturbance.

For anyone involved in dredging, land reclamation, or environmental cleanup, seeing what an amphibious excavator with a rotating grapple can do is a real eye-opener. It is proof that heavy machinery can be a tool for restoration, balancing the demands of a project with the responsibility to protect our natural spaces.

Maximizing Your Return on Investment

When you are looking at a new piece of equipment, it is easy to get fixated on the price tag. But with a rotating grapple attachment, the initial cost is just the start of the story. The real value, the true return on your investment, shows up in how it fundamentally changes your operations for the better. We are talking about a serious boost to efficiency, a safer worksite, and a noticeable drop in your long-term costs.

The most obvious win is how much less you have to move the excavator itself. Think about it: with a standard bucket or a fixed grapple, your operator is constantly repositioning the entire machine just to get the right angle on a piece of debris. A rotating grapple lets them stay put, using the attachment's spin to grab, sort, and place materials with precision.

This one simple change creates a domino effect across the whole job.

Driving Down Costs and Speeding Up Timelines

All that extra movement costs money. When your excavator is not constantly shuffling around, it is burning a lot less fuel, one of your biggest operating expenses. In fact, on some material handling jobs, simply cutting out unnecessary machine movement can reduce fuel consumption by as much as 25%.

This newfound efficiency naturally makes your projects move faster. Let's picture a real-world scenario: you are faced with a massive pile of mixed demolition debris that needs sorting.

- Without a rotating grapple: The operator has to crawl the machine back and forth, turning and repositioning to separate wood from metal and concrete. It is a slow, fuel-guzzling process.

- With a rotating grapple: The operator can park the excavator in one spot. From there, they can use the 360-degree rotation to methodically pick through the pile, swinging around to load different dumpsters with incredible speed and accuracy. It is not uncommon to see sorting times cut by more than half.

The bottom line is that handling materials more efficiently leads to faster cycle times and a huge jump in productivity. A job that used to eat up an entire day can now be knocked out in just a few hours, freeing up your machine and operator for the next task on the list.

A Safer, More Productive Job Site

The benefits go well beyond the balance sheet. A rotating grapple makes your worksite a much safer place. Its precision gives operators the confidence to handle tricky or unstable loads, like tangled rebar or bulky chunks of concrete, from a stable distance. This is a game-changer because it keeps ground workers out of the immediate danger zone.

By reducing the need for manual labor in high-risk areas, you dramatically lower the risk of accidents and injuries. That not only protects your crew but also helps you avoid costly project delays and potential liability issues. When you invest in a rotating grapple, you are not just buying a tool, you are investing in a more efficient, profitable, and secure operation.

How to Choose the Right Rotating Grapple

Choosing the right rotating grapple is not just a simple purchase. It is a decision that echoes through every job, affecting your efficiency, safety, and ultimately, your bottom line. Get it wrong, and you are stuck with sluggish performance, accelerated wear and tear, or worse, a dangerously unstable machine. Nail the selection, and your excavator becomes a precision tool operating at its peak potential.

The key is to stop thinking of the grapple and the excavator as two separate pieces of equipment. They are a single, integrated system. A perfect match means the attachment complements the carrier's specs, giving you the stability and hydraulic muscle needed to tackle tough jobs.

Matching the Grapple to Your Excavator

Before you even start browsing grapple models, you need to have a deep understanding of your excavator's limits and capabilities. The two most critical factors are the attachment's weight and its thirst for hydraulic power.

Excavator Weight and Class: Every excavator has a designated weight class, usually measured in tons. The grapple you choose must fit comfortably within that range. An overweight attachment is a recipe for disaster, throwing off the machine's balance and creating a serious tipping hazard.

Hydraulic Flow and Pressure: The grapple's powerful rotation and clamping force come directly from your excavator's hydraulic system. You have to ensure your machine's hydraulic flow (gallons per minute) and pressure (PSI) can meet the grapple’s demands for crisp, responsive control.

A mismatch here is a classic performance killer. Too little power starves the grapple, resulting in frustratingly slow cycle times and a weak grip. Too much can overwhelm the system, leading to costly damage. Always check the manuals or talk to an expert to confirm you have a compatible pair.

Selecting the Right Jaw and Tine Configuration

With the technical specs locked in, the next step is all about the job itself. The design of the jaws (or shells) determines what a grapple is good at. You need to think carefully about the kind of material you will be handling day in and day out.

For example, a demolition grapple is built like a tank with reinforced, high-strength steel to handle the brutal punishment of a demo site. Sorting grapples, on the other hand, often have perforated or skeletonized shells. This clever design lets fine debris like dirt and dust fall through, leaving you with only the larger materials. In recycling, where clean material is everything, this feature is indispensable. Looking into the most popular marsh runner attachments can offer more perspective on how specialized attachments are paired with machines for specific environments.

There is no question that these tools are becoming more essential across construction, forestry, and waste management. The market for heavy-duty grapples was valued at roughly USD 1.5 billion in 2024 and is projected to climb to around USD 2.8 billion by 2033. This surge shows just how much the industry relies on specialized attachments for smarter, faster material handling.

Keeping Your Grapple in Top Shape: Maintenance and Safety

A rotating grapple excavator is a serious piece of machinery. To keep it running reliably and, more importantly, safely, you cannot just cross your fingers and hope for the best. A solid routine for maintenance and on-the-job safety is not just a good idea, it is what separates the pros from the amateurs. Taking care of your gear extends its life, keeps your crew safe, and prevents that dreaded, budget-wrecking downtime.

It all starts before you even turn the key. A daily walk-around is not just a formality. It is your first and best defense against small problems turning into massive headaches. This quick check helps you catch issues early and ensures the machine is ready for a hard day's work.

Your Daily Pre-Operation Check

Before every shift, the operator needs to give the grapple a thorough look-over. This is not about just checking boxes on a form. It is about getting to know your machine and what looks "right."

Here’s a simple checklist to run through:

- Hydraulic Lines: Scan every hose and fitting. You are looking for leaks, cracks, or any signs of rubbing and wear. A blown hydraulic line means an instant loss of control, which is a massive safety risk.

- Teeth and Jaws: Check the grapple’s business end. Are the teeth worn down, cracked, or missing? Damaged teeth will not grip properly and can break right off under a heavy load.

- Grease Points: Know where every grease zerk is on the grapple and the rotator. A daily shot of grease is crucial for keeping pins, bushings, and the rotation system moving smoothly and preventing premature wear.

- Frame and Welds: Give the grapple’s main body a once-over. Look for stress fractures in the welds or any cracks forming on the frame and mounting brackets.

The single best thing you can do for your equipment's lifespan and your ROI is to maintain it properly. Regular service stops minor problems from becoming project-stopping failures, keeping you on schedule and your team out of harm's way.

Safety on the Job Site

A well-maintained machine is only half the battle. The person in the driver's seat is the other half. The incredible precision of a rotating grapple brings its own set of rules to the job site that everyone needs to respect.

When you are dealing with specialized gear, like amphibious excavators in tough spots, having a go-to expert for repairs is a game-changer. You can see how professional Hydratrek service keeps this type of machinery ready for anything.

Here are the core safety rules to live by:

- Set Up a "No-Go" Zone: Always mark out a clear, safe radius around the excavator while it is working. Nobody enters that zone without a clear signal from the operator. Period.

- Know Your Limits: Never, ever try to lift something heavier than what the grapple and the excavator are rated for. Overloading is the fastest way to make the machine unstable and risk a tip-over.

- Get a Good Grip: Before you lift and swing, make sure the material is locked in the jaws tight. A load that shifts or drops mid-air is a danger to everyone and everything below.

Partnering with Wilco for Your Equipment Needs

Getting the right equipment is one thing, but finding the right partner to back it up can make or break your project. A rotating grapple excavator is an incredibly useful tool for tricky material handling jobs, but its real value shines in tough spots like wetlands where standard machinery just cannot go.

This is where our experience at Wilco Manufacturing really comes into play. We do not just sell you a part. We deliver a complete solution, from our custom amphibious undercarriages to the exact attachments your job demands.

It is no surprise that the global market for these attachments is growing. More and more industries are seeing how much more efficient they can be. With major players like SENNEBOGEN, Liebherr, and Volvo in the mix, it just goes to show how critical reliable, high-performance equipment has become.

Our entire focus is making sure your equipment setup is dialed in perfectly for the job ahead. We build the tough, dependable amphibious solutions that keep your work on track, whether you need a full custom build from the ground up or are looking into rentals.

Don't guess when it comes to your project's success. Talk with our team of specialists, and let's put together an equipment package that is built specifically for the challenges you are facing.

Reach out to Wilco Manufacturing today. We are ready to hear about your project and show you how our integrated approach can make all the difference.

Frequently Asked Questions

When you are looking at attachments, it is easy to get lost in the specs. Let's clear up a few of the most common questions we hear from operators and project managers about rotating grapples.

What’s the Real Difference Between a Rotating and a Fixed Grapple?

Think of it as the difference between your wrist and your elbow. A fixed grapple only opens and closes, kind of like your elbow joint. To change the angle of what you are holding, you have to move your entire arm, or in this case, the entire excavator.

A rotating grapple excavator, on the other hand, adds that crucial wrist-like movement. With full 360-degree rotation, your operator can pick up a log, a concrete slab, or a bundle of scrap, then twist and place it with incredible precision, all without repositioning the machine. That simple addition makes a world of difference in saving time, cutting fuel costs, and preventing unnecessary wear and tear on the ground.

Can I Put a Rotating Grapple on Any Excavator?

Absolutely not, and this is a critical point. You have to think about compatibility. Every attachment is designed for a specific excavator weight class and requires a certain hydraulic pressure and flow rate to function correctly.

Putting the wrong size grapple on your machine is a recipe for disaster. At best, it will perform poorly. At worst, you risk dangerous instability or could blow out your excavator’s entire hydraulic system. It is always smart to talk with an equipment pro, like our team at Wilco, to guarantee a safe and productive match for your machine.

How Does This Attachment Actually Make a Job Site Safer?

Safety gets a major boost because the operator can handle tricky materials from a secure distance. That precision means you do not need a crew member on the ground guiding a load or working near a shaky pile of debris during demolition.

By keeping your team out of harm's way, a rotating grapple excavator drastically reduces the chance of accidents and injuries in those high-risk zones. It is about giving the operator total control from inside the cab.

Ready to boost your project's efficiency and safety? Wilco Manufacturing has the expertise to equip you with the right amphibious solutions and attachments for any challenge. Contact us today to discuss your equipment needs with an expert.