When planning a project involving heavy machinery, one of the most critical figures to establish is the equipment's weight. For a versatile machine like the Cat 336 excavator, the standard operating weight is approximately 37,000 kg (81,900 lbs). This number isn't just a dry weight. It's a real-world figure that accounts for the base machine, standard attachments, a full tank of fluids, and an operator.

Understanding this weight is the cornerstone for all logistical planning, from transportation and site preparation to critical safety assessments. For decision-makers in industries like construction, dredging, and environmental cleanup, this single metric influences every phase of an operation.

Breaking Down the Cat 336 Operating Weight

The operating weight of a Cat 336 is more than a simple specification. It is the foundation of the machine's stability and power. For anyone managing a construction, dredging, or land reclamation project, this figure directly impacts transport logistics, ground pressure calculations, and lifting capacity. The substantial mass gives the excavator the stability required for heavy digging and lifting, making it a true workhorse on demanding job sites.

This robust frame and significant weight also make the Cat 336 an excellent platform for specialized modifications. Official technical specifications clarify that this weight includes a 90% fuel load and a 75 kg operator, which provides a consistent baseline for comparing different machine configurations.

To provide a clearer picture, here is how the standard weight typically breaks down.

Cat 336 Excavator Standard Weight Configuration

This table summarizes the typical components contributing to the standard operating weight of a Cat 336 excavator.

| Component | Approximate Weight Contribution |

|---|---|

| Base Machine (Chassis, Cab, Engine) | 20,000 – 22,000 kg (44,000 – 48,500 lbs) |

| Standard Boom & Stick | 4,500 – 5,500 kg (9,900 – 12,100 lbs) |

| Standard Bucket (e.g., 1.88 m³) | 1,500 – 2,000 kg (3,300 – 4,400 lbs) |

| Counterweight | 6,500 – 7,500 kg (14,300 – 16,500 lbs) |

| Undercarriage (Tracks, Rollers) | 8,000 – 9,000 kg (17,600 – 19,800 lbs) |

| Fluids (Fuel, Hydraulic Oil, etc.) |

Note: These are estimates. Exact weights vary based on specific boom, stick, and bucket configurations.

Understanding these individual components helps in appreciating how quickly the total weight adds up and why every part plays a role in the machine's balance and performance.

From Standard Specs to Specialized Solutions

While the factory weight is impressive, for many challenging projects, it's just the starting point. That solid base allows for powerful custom solutions.

- A Foundation for Power: The machine's inherent weight provides the raw stability needed to handle high breakout forces and operate heavy, demanding attachments without compromise.

- Critical for Logistics: Knowing the base weight is non-negotiable for arranging legally compliant transportation and ensuring the job site can support the machine's arrival and movement.

- Adaptability for Tough Terrain: The Cat 336's strong, heavy build makes it a perfect candidate for modifications, like adding an amphibious undercarriage for work in wetlands, swamps, or dredging projects.

At Wilco Manufacturing, we leverage this powerful base to engineer custom amphibious excavator models. These specialized machines are designed to conquer challenging environments where standard equipment simply cannot operate. You can see how we adapt this platform across our different Wilco Amphibious Excavator Models.

How Key Components Influence Total Weight

The Cat 336's specification sheet provides a starting point, but the real-world weight on your job site can be a different story. Every major component you add or change, from the counterweight to the bucket, plays a role in the machine's final operating weight and performance. Getting this configuration right is crucial for matching the excavator to the demands of your project, whether it involves pipeline installation or land reclamation.

This isn't just about adding weight. It's about strategic configuration. Your choices directly affect stability, ground pressure, and what the machine is truly capable of, whether you're doing heavy lifting or bulk earthmoving.

Counterweights and Undercarriage

When it comes to significant weight additions, the counterweight and the undercarriage are the two heaviest contributors. These components are the foundation of the machine's balance and its ability to travel across the site.

-

Counterweight: A standard counterweight for the Cat 336 will add a hefty 6,800 kg (14,990 lbs) to the total. Its job is simple but critical: to keep the machine stable by offsetting the forces from the boom, stick, and a fully loaded bucket during tough digging and lifting.

-

Track Shoes: The type of track shoes you select makes a surprising difference. For example, opting for wider 850 mm triple grouser shoes adds significantly more mass than standard pads. The trade-off is much lower ground pressure, which is exactly what you need when working on soft or unstable ground.

This kind of component swapping is essential when facing challenging terrain. For instance, in swamps or marshlands, the undercarriage isn't just a component. it is the key to the entire operation. This is where amphibious equipment excels. Wilco Manufacturing engineers and builds custom hydraulic amphibious undercarriages that replace the standard tracks entirely. This modification gives the machine the flotation it needs to work where conventional equipment would sink, a perfect example of how a single component change can redefine where an excavator can operate.

How Excavator Weight Impacts Performance and Stability

For excavators, weight is a critical factor that directly translates to digging power and on-the-job safety. The considerable mass of a machine like the Cat 336 allows it to generate the immense breakout force needed to tear through compacted soil or rock. This weight acts as an anchor, keeping the machine firmly planted so it can apply its full hydraulic power without tipping or losing traction.

This inherent stability is a cornerstone of safe operation. The machine's weight is carefully distributed to maintain a low center of gravity, which is essential for minimizing the risk of rollovers, especially when lifting heavy loads or working on uneven ground. A stable base gives the operator the confidence to push the machine to its limits, which ultimately means greater productivity and project efficiency.

Weight as a Performance Metric

The link between an excavator's weight and its power is clear. The Cat 336 excavator weight, at around 37,200 kg (82,000 lbs), provides the solid foundation required for high-performance digging. This stable platform allows the machine to achieve impressive boom breakout forces over 300 kN and stick forces exceeding 200 kN, placing it at the top of the 30-40 metric ton class. For a deeper dive into these numbers, the official Cat 336 technical data sheet has the full breakdown.

This balance of weight and stability is even more important in specialized applications. Consider amphibious excavators, which are often built on a Cat 336 chassis. The machine's core weight and stability are what allow it to support massive, buoyant pontoons. This modification makes it possible to tackle tough jobs like installing pipelines in wetlands or reclaiming coastal land, tasks that would be impossible for standard equipment.

Navigating Transport Weight and Logistics

Getting an excavator of this size to a job site is a serious logistical undertaking. Before moving a Cat 336, you must understand the critical difference between its operating weight and its transport weight. To remain compliant with road and bridge regulations, the hefty 37,000 kg operating weight must be significantly reduced.

This process involves disassembling the machine by removing its heaviest modular components. Only then can it be loaded onto a lowboy trailer for transport.

Planning for a Successful Move

A successful move boils down to solid planning. Getting the details right from the beginning is the only way to sidestep expensive delays, ensure crew safety, and keep your budget and schedule on track.

- Component Removal: The counterweight and bucket are typically the first components to be removed. The counterweight alone can weigh over 6,800 kg (14,990 lbs), so it and the bucket almost always require separate transport.

- Trailer Selection: A multi-axle lowboy trailer is necessary for this job. This is essential for distributing the machine's immense weight evenly and staying within per-axle load limits.

- Permitting and Routing: Planning the route and securing the right permits go hand in hand. You will need to obtain overweight and oversize permits, and the approved route will dictate exactly which roads and bridges you can safely travel.

This entire process underscores the importance of modular design in heavy equipment. The ability to easily remove and re-attach major parts is not just a convenient feature, it's a logistical necessity for modern construction and dredging operations.

It is also crucial to confirm that your transport provider meets all CDL requirements for heavy haul to ensure the move is both legal and safe. This same modular thinking applies to specialized equipment, like the amphibious undercarriages from Wilco. These systems are built for efficient transport, ensuring your amphibious excavator can get to even the most remote sites ready for action.

How Attachments Impact Overall Weight and Balance

An excavator's true versatility comes from its attachments, but every tool you add changes the machine's total weight and center of gravity. The standard digging bucket is just the baseline. When you swap it for heavy-duty attachments like hydraulic hammers, powerful shears, or large grapples, you can easily add thousands of pounds to the front end. This directly affects the machine's balance, stability, and lifting capacity.

This extra mass up front is not something to take lightly. For instance, a heavy rock bucket used in a quarry pulls the center of gravity forward, meaning the operator must be much more deliberate to prevent tipping, especially when working on an incline. The same principle applies to any specialized tool. Understanding how that attachment affects the machine's performance is key to getting the job done safely and efficiently. If you're looking into specialized tools, our guide on the most popular Wilco Marsh Runner attachments is a great resource.

A Quick Look at Common Attachment Weights

To put this into perspective, let's look at the estimated weights for some common attachments you might see on a Cat 336. The weight can vary depending on the manufacturer and specific model, but this table gives a solid general idea.

| Attachment Type | Estimated Weight Range (kg / lbs) | Primary Application |

|---|---|---|

| General Duty Bucket | 1,350 – 1,800 kg / 3,000 – 4,000 lbs | General digging, trenching, and material handling |

| Hydraulic Hammer | 2,250 – 3,200 kg / 5,000 – 7,000 lbs | Demolishing concrete, breaking rock |

| Compaction Wheel | 1,150 – 1,600 kg / 2,500 – 3,500 lbs | Compacting soil in trenches and on slopes |

| Grapple (Demolition) | 2,000 – 2,700 kg / 4,400 – 6,000 lbs | Sorting and handling demolition debris |

| Hydraulic Shear | 2,700 – 4,100 kg / 6,000 – 9,000 lbs | Cutting steel beams and processing scrap metal |

As you can see, swapping from a standard bucket to a hydraulic shear can add over 5,000 lbs to the end of the stick. Always consult the manufacturer's specifications for both the excavator and the attachment to confirm compatibility and stay within safe operating limits.

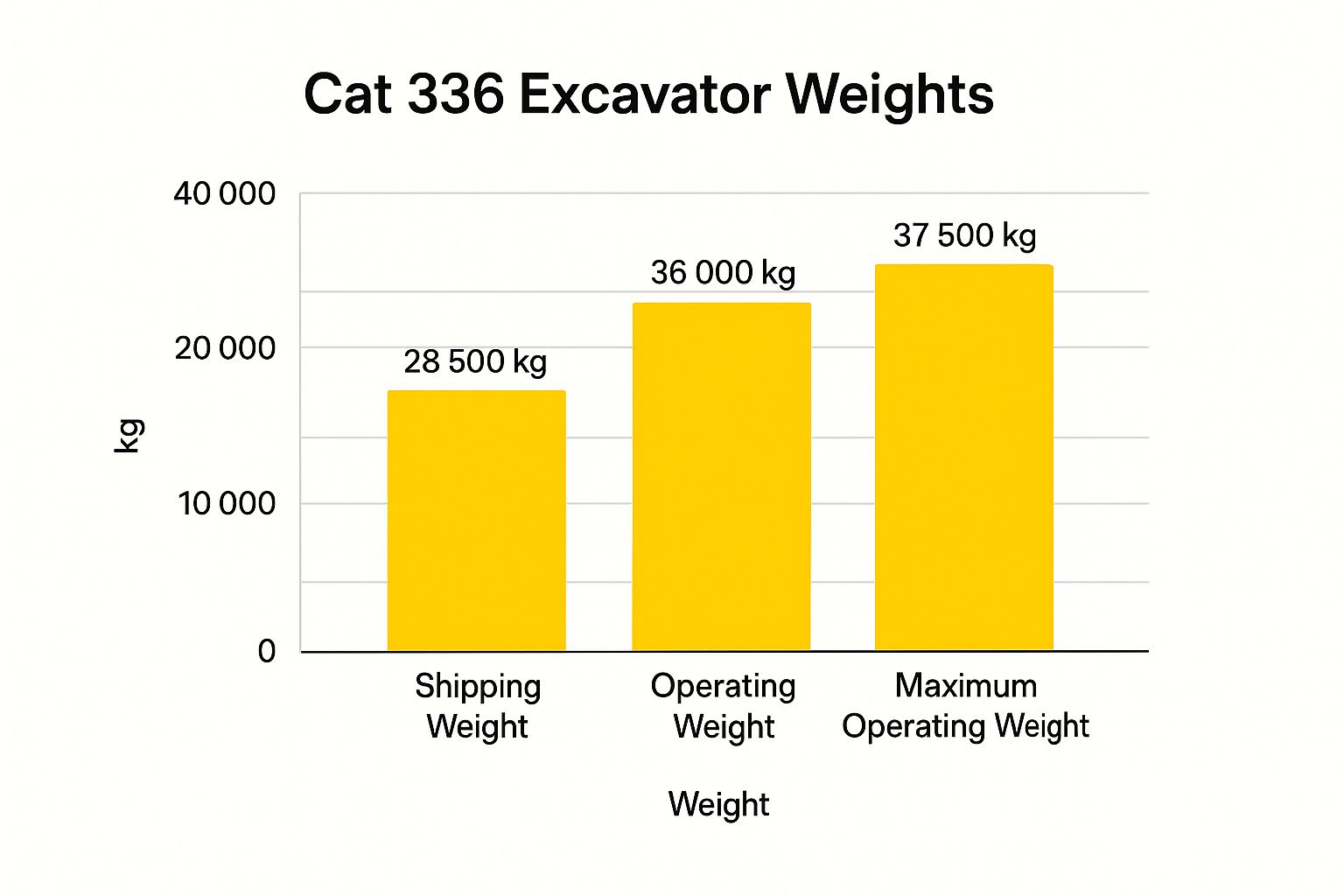

Visualizing Key Weight Metrics

This chart breaks down the key weight differences you'll encounter with the Cat 336, from its leanest shipping configuration to its standard and maximum operating weights.

It’s a clear visual that drives home just how much the machine’s total weight can climb once you add fuel, fluids, and heavy-duty attachments.

Taking the Cat 336 into Wetlands and Water

The sheer power and size of the Cat 336 make it a perfect starting point for an amphibious conversion, which is what we specialize in at Wilco Manufacturing. A standard excavator is built for solid ground, but critical work, from dredging and environmental remediation to pipeline projects, often happens in swamps, marshes, and waterlogged areas where conventional machinery would get stuck in minutes.

That is the problem we solve. We engineer a solution by removing the factory tracks and fitting the excavator with a custom-built hydraulic amphibious undercarriage. This single modification completely redefines how the machine interacts with its environment.

Shifting the Weight for Buoyancy and Mobility

The secret to making a heavy machine work on soft ground isn't just about managing the total Cat 336 excavator weight. it's about redistributing that weight intelligently. Our amphibious undercarriages are essentially large, buoyant pontoons that massively expand the machine's footprint.

This design distributes the excavator's entire mass over a much larger surface area, resulting in an exceptionally low ground pressure, often below 3 PSI. It is this principle that allows a massive machine to literally float on water or move across terrain that would not even support a person's weight.

By spreading the machine's considerable weight over such a huge area, the amphibious Cat 336 can operate effectively in environments that would instantly trap standard heavy equipment.

Ultimately, this conversion is a masterclass in practical engineering. We take a world-class excavator and re-imagine it to conquer the toughest wetland and waterway jobs, turning what was once a logistical nightmare into a solvable challenge.

Cat 336 Weight: Your Questions Answered

When you're trying to figure out the logistics for a big machine like the Cat 336, the details matter. Let's break down some of the most common questions project managers have about its weight to help you plan your next job with confidence.

How Much Does the Cat 336 Counterweight Weigh?

The standard counterweight on a Cat 336 is a serious piece of hardware, weighing approximately 6,800 kg (14,990 lbs). This massive block is absolutely essential for keeping the excavator stable, especially when you're lifting heavy loads or have the boom fully extended.

For transport, the counterweight is almost always the first component removed. This is a key step in reducing the machine to a legal shipping weight.

What’s the Difference Between Operating and Transport Weight?

This is a crucial point for anyone handling logistics. Think of it this way:

-

Operating Weight: This is the machine's "ready-to-work" weight. It includes the excavator itself, a full tank of fuel, all other fluids, an operator in the cab, and a standard bucket attached. It’s the total weight you are dealing with on the job site.

-

Transport Weight: This is the stripped-down version. To meet road and bridge weight limits, heavy components like the counterweight and bucket are removed. The resulting figure is the machine's lighter transport weight, which is what you'll use for planning your hauling permits and routes.

Does an Amphibious Undercarriage Increase the Weight?

Yes, swapping out standard tracks for an amphibious undercarriage adds a significant amount of weight to the Cat 336.

But here is the clever part: that extra weight is distributed across large, buoyant pontoons. This design creates incredibly low ground pressure, allowing a machine of this size to work in soft swamps or even float on water. It is an engineered solution for getting heavy-duty power into places conventional equipment simply cannot reach.

When your project involves wetlands, swamps, or waterways, standard equipment just won't cut it. Your project demands a specialized solution. As a global leader in amphibious equipment, Wilco Manufacturing has the expertise to deliver the right machinery for the toughest jobs. We provide practical solutions that keep your projects moving forward in challenging environments.

Contact us today to discuss your project needs, or explore our full range of amphibious equipment at https://wilcomfg.com.