Investing in the right dredging equipment is a critical decision for any major waterway, environmental, or infrastructure project. From a versatile amphibious excavator to a powerful cutter suction dredger, the machine you choose becomes the backbone of your entire operation. A smart investment boosts productivity and profitability, while the wrong choice can lead to costly delays.

This guide provides the practical, real-world knowledge needed to navigate the market with confidence. We will cover the different types of dredgers, explain key technical specifications, and show how to match the right equipment to your project challenges, ensuring you make a strategic decision that drives success.

Planning Your Dredging Equipment Purchase

Buying heavy machinery is a strategic move that directly impacts project schedules, crew efficiency, and your company's bottom line. The right equipment is a force multiplier, driving productivity and delivering an impressive return on investment. The wrong piece can lead to crippling delays and on-site hazards.

The Growing Demand for Modern Dredging Solutions

The need for effective dredging equipment is rising worldwide. Fueled by a surge in infrastructure development and critical environmental restoration projects, the global dredging market is expanding rapidly. One recent report projects the market will grow significantly, underscoring that projects are becoming more complex and the demand for advanced, reliable machinery has never been higher. Having the right tool for the job is no longer a luxury, it is a necessity.

Navigating Your Equipment Acquisition

Before examining spec sheets, it is wise to establish an acquisition strategy. This involves determining how you will fund the purchase and deciding if buying outright is the best path for your current projects.

-

Financing Your Purchase: Arranging funding is the first hurdle. It is worth exploring dedicated equipment financing solutions that can help you secure the asset while maintaining healthy cash flow.

-

Buying vs. Renting: For short term projects or to test a specific machine before committing, exploring options like amphibious excavators for rent can be a smart, flexible alternative to a major capital expense.

By clarifying your financial and operational plan first, you can focus your search and find dredging equipment that truly aligns with your business goals.

Exploring Your Dredging Equipment Options

Entering the world of dredging equipment can feel complex. Instead of getting bogged down in technical specs immediately, it is more helpful to understand what these machines do in real world applications. By understanding their primary functions, you can quickly narrow down the right tool for your job.

The dredging world is broadly divided into two main categories: hydraulic dredgers and mechanical dredgers. Each type operates on a different principle and excels in different scenarios. Understanding how they work is the first step toward a smart purchase.

Hydraulic Dredgers: The Volume Movers

When a project requires moving a massive amount of material, a hydraulic dredger is the solution. These are the workhorses of large scale projects. They function like giant, powerful underwater vacuum cleaners, turning sediment into a pumpable slurry by mixing it with water and transporting it through a pipeline.

-

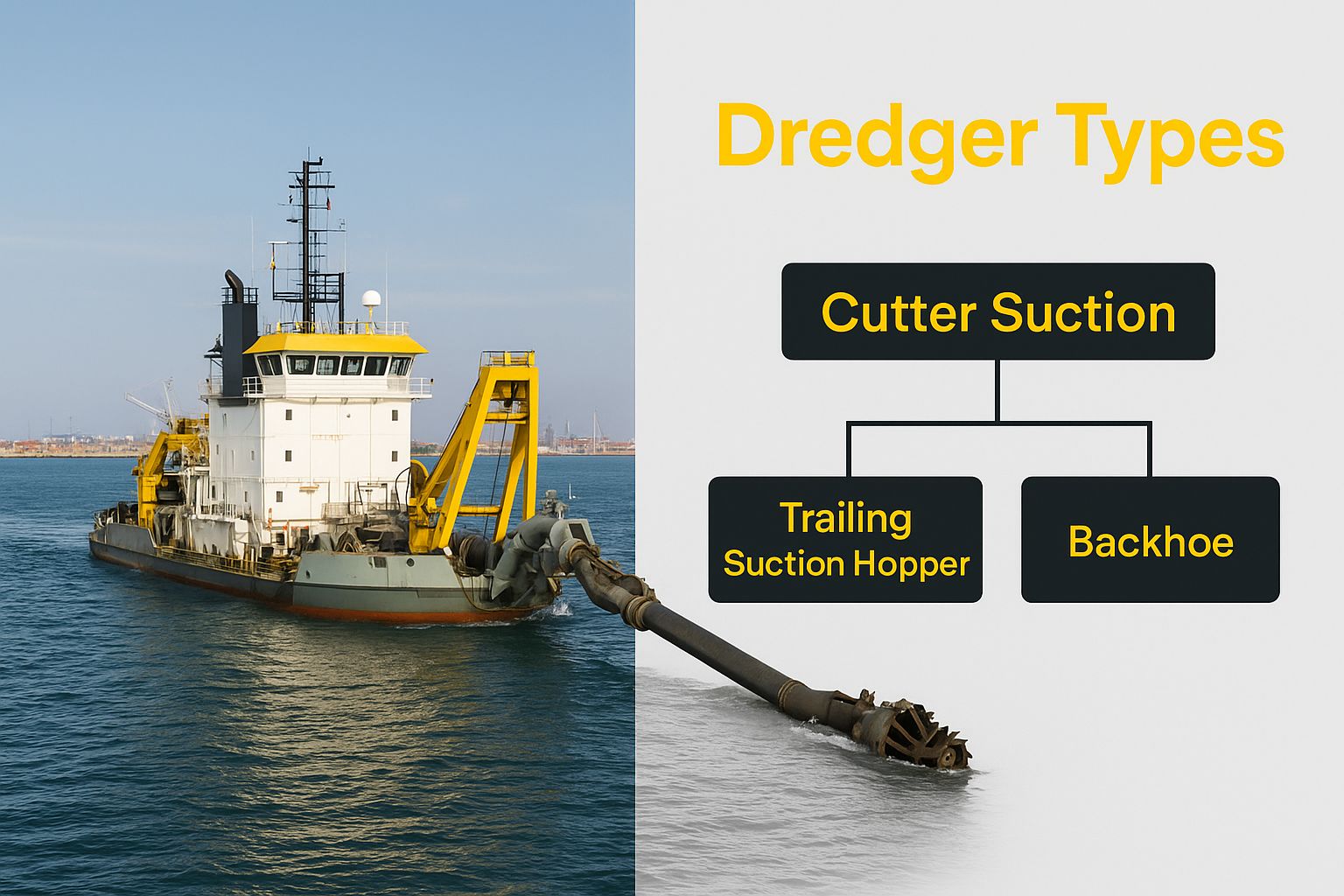

Cutter Suction Dredgers (CSDs) are what most people picture when they think of dredging. They feature a rotating cutter head that breaks up hard packed soil, clay, and even soft rock before suctioning the material. This raw power makes them ideal for major projects like creating new channels, expanding ports, and land reclamation where production volume is paramount.

-

Trailing Suction Hopper Dredgers (TSHDs) are self propelled ships that drag suction pipes along the seabed. They are perfect for maintaining busy shipping lanes because they can collect material, store it in an onboard hopper, and sail away for disposal, all without blocking traffic for long periods.

If your project involves deepening a major port or building new coastline, a hydraulic dredger is almost certainly the tool you need.

Mechanical Dredgers: The Precision Specialists

On the other side are mechanical dredgers. These machines do not pump, they physically dig, grab, and lift material out of the water. Their action is more direct and controlled, making them the go to choice for smaller, precise, or environmentally sensitive jobs. It is less about sheer volume and more about accuracy.

Mechanical dredgers are at their best when precision is the top priority. Their ability to excavate a specific spot with a high degree of control is invaluable for targeted sediment removal, debris cleanup, and working in tight spots like marinas or adjacent to existing structures.

This category includes machines that look and act much like their land based counterparts.

-

Backhoe Dredgers are essentially a powerful excavator arm mounted on a stable barge. They deliver significant digging force and are excellent for breaking up compacted material, removing large debris, or handling underwater construction with pinpoint accuracy.

-

Clamshell (or Grab) Dredgers use a hinged, bucket like grabber to scoop material. They are highly effective for removing loose to medium packed sediment and are often used to maintain depths in docks and alongside quay walls.

This visual helps place these different dredging technologies into the broader landscape of waterway projects.

As the image suggests, the sheer scale and power of cutter suction dredgers often position them at the center of major marine engineering efforts.

To make these distinctions clearer, here is a quick comparison of the primary dredging equipment types.

Comparing Dredging Equipment Types

| Equipment Type | Best For | Operational Environment | Key Advantage |

|---|---|---|---|

| Cutter Suction Dredger | Large-scale capital projects, land reclamation | Rivers, ports, open water | High production, breaks up hard material |

| Trailing Suction Hopper Dredger | Maintenance of busy waterways | Harbors, shipping channels | Self-contained, mobile, minimal disruption |

| Backhoe Dredger | Precision digging, debris removal | Confined areas, underwater construction | High accuracy, powerful digging force |

| Clamshell/Grab Dredger | Maintenance near structures | Docks, marinas, quay walls | Good for loose material, vertical reach |

| Amphibious Excavator | Environmentally sensitive areas | Swamps, wetlands, shallow water | Unmatched access, minimal ground impact |

This table provides a high level overview, but one machine on this list stands in a category of its own.

The Amphibious Excavator: The Ultimate Problem-Solver

When a project is located in the challenging transitional zone between land and water, the amphibious excavator is the solution. This is not just another dredger, it is a specialized problem solver built for the toughest environments. It merges the functionality of a hydraulic excavator with a unique pontoon undercarriage, allowing it to work directly in swamps, wetlands, and shallows where no traditional barge could float.

Amphibious excavators are the answer for projects in sensitive or inaccessible locations. They can propel themselves through mud and shallow water, making them indispensable for:

- Environmental Remediation: Carefully removing contaminated sediment from wetlands without building destructive access roads.

- Pipeline Construction: Clearing paths and digging trenches through swampy terrain that would bog down any conventional machine.

- Shoreline Restoration: Rebuilding eroded coastlines and creating natural habitats with the smallest possible environmental footprint.

Wilco Manufacturing is a leader in these incredibly versatile machines, offering a range of equipment for dredging that thrives in these exact conditions. Their design provides the stability and mobility to perform precise work on soft, unstable ground, offering a unique solution to some of the most complex challenges. By understanding these core equipment categories, you can begin building a shortlist of options that truly fit your project's needs.

Decoding Key Technical Specifications

A specification sheet tells a story, but you have to know how to read it. When looking at heavy machinery, those numbers are not just abstract figures, they are a direct reflection of what a machine can do on a job site. Understanding how to translate specifications into real world performance separates a smart investment from a costly mistake when searching for dredging equipment for sale.

Focusing on the right metrics allows you to see past the price tag and get a true sense of a machine's capabilities. For any dredging project, a few make or break numbers will determine whether you succeed or struggle. These specs tell you how deep the machine can dig, how much material it can move, and how efficiently it will get the job done.

Core Performance Metrics

Every spec sheet will present a few key numbers upfront. Think of these as the machine's vital signs, a quick snapshot of its power and function.

-

Dredging Depth: This is simply how deep the equipment can effectively work, measured from the water's surface. For shallow harbor maintenance, a dredger rated for 30 feet might be perfect. But clearing a 60-foot shipping channel requires a completely different class of machine.

-

Pump Capacity (for hydraulic dredgers): Usually measured in cubic yards or meters per hour, this spec indicates the total volume of the water and sediment slurry the pump can handle. A higher number means moving material faster, which is critical for large scale projects like land reclamation.

-

Engine Power: Listed in horsepower (HP) or kilowatts (kW), this is the raw muscle behind the entire operation. It drives the cutterhead, powers the pump, and gives the machine the strength to break through tough materials. Insufficient power results in an inefficient machine that bogs down when needed most.

These three metrics provide a solid baseline. But for specialized gear like amphibious excavators, the most important specs relate to how the machine handles its uniquely challenging environment.

Stability and Mobility in Amphibious Design

For projects in swamps, wetlands, or along soft coastlines, standard performance numbers are only half the picture. The real magic of an amphibious excavator lies in its undercarriage, which delivers the stability and mobility to work where nothing else can. When evaluating this kind of equipment, your focus should shift to its specialized components.

An amphibious excavator’s performance is measured not just in digging depth but in its ability to safely traverse and operate on ground that cannot support the weight of traditional heavy machinery. The engineering behind its pontoons and spuds is what makes sensitive environmental work possible.

Here are the key design elements to examine:

-

Pontoon Construction: The pontoons are the heart of the machine. Look for specs detailing high strength, corrosion resistant steel and multiple watertight compartments. This multi compartment design is a non negotiable safety feature, keeping the machine afloat even if one section is punctured.

-

Hydraulic Spuds: These are heavy duty legs that extend down to anchor the machine to the ground. They are absolutely essential for providing stability while digging, preventing the excavator from shifting or tipping in soft mud or a current. A machine with robust, independently controlled spuds is a much safer and more effective tool.

-

Propulsion System: Amphibious excavators use their own hydraulic system to power the tracks on the pontoons. The design of the track chains and pads determines how well the machine can crawl through mud, shallow water, and thick vegetation.

By understanding what these specialized features do, you can look at a spec sheet and get a real feel for how the machine will perform in those tricky transition zones between land and water. The engineering behind Wilco’s amphibious hydraulic undercarriages is a prime example of design that prioritizes this crucial stability and mobility. With this knowledge, you can analyze any spec sheet like an expert and choose a machine truly built for the job.

Matching the Right Dredger to Your Project

This is where planning meets reality. Connecting the specifications on a data sheet to the practical challenges of a job site is what distinguishes a smart purchase from a costly one.

We can discuss theory all day, but seeing how different machines solve specific problems makes it all click. Let's walk through a few common project challenges to see how unique problems demand unique equipment solutions.

Scenario 1: Environmental Remediation in Sensitive Wetlands

Environmental cleanup projects demand precision and a light touch. The primary challenge is removing contaminated sediment without damaging the delicate ecosystem you aim to protect. Building an access road is not an option, as it would destroy the very habitat you are there to restore.

- The Main Hurdle: Accessing the work area with minimal ground disturbance and then excavating with surgical precision.

- The Wrong Tool: A large cutter suction dredger is overkill and would be far too disruptive. A barge mounted backhoe may not be feasible if the water is too shallow or choked with vegetation.

- The Right Solution: An amphibious excavator is the clear winner. It can propel itself to the site through mud and shallow water, eliminating the need for destructive access paths. Its low ground pressure protects sensitive soil and plant life. With an attachment like a clamshell bucket, it can carefully lift out contaminated material, meeting the strictest environmental regulations.

Scenario 2: Pipeline Construction Across a Swamp

Pipeline projects frequently cross swamps or marshlands, creating a massive logistical challenge. The ground is too soft for standard heavy equipment, but the water is often too shallow or filled with debris for a traditional barge. You must clear a path and dig a trench safely and efficiently.

- The Main Hurdle: Operating heavy equipment on saturated, unstable ground that cannot support its weight.

- The Wrong Tool: A standard excavator would get stuck in minutes. Floating a dredger might be impossible in shallow water with obstacles like downed trees.

- The Right Solution: Again, the amphibious excavator proves its value. Its ability to work in these "in-between" environments is unmatched. It can clear vegetation, dig the pipeline trench, and handle materials without needing solid ground. For larger jobs that also require pumping material away, a specialized amphibious dredge unit combines this incredible mobility with serious pumping power.

Scenario 3: Large-Scale Land Reclamation

When creating new land for a port expansion or coastal development, volume is the name of the game. The goal is to move millions of cubic yards of sand as quickly as possible. Here, raw production power trumps precision every time.

When your entire project boils down to moving massive amounts of material over long distances, the production rate is the only metric that truly matters. The equipment must run continuously at high volume to keep the project on schedule and on budget.

- The Main Hurdle: Excavating and pumping a massive volume of material from an offshore borrow pit to the reclamation site.

- The Wrong Tool: Any mechanical dredger, including an amphibious excavator, lacks the pumping muscle for this type of work. They are built for precision, not for moving mountains of sand.

- The Right Solution: The large cutter suction dredger (CSD) is the undisputed king of this domain. Its powerful cutter head can break through compacted seabed materials, and its massive pumps can push the slurry through miles of pipeline directly to the fill site. This is a perfect example of matching a machine’s core strength, in this case immense production capacity, to the project’s primary demand.

This focus on matching the right machine to the job drives the industry. The global dredging market, including both equipment and services, is a multi billion dollar industry and continues to grow, powered by exactly these kinds of major infrastructure projects. A recent dredging market analysis offers great insights into what is fueling this growth.

Choosing the Right Equipment Partner

When you are in the market for dredging equipment, the machine you choose is only half the equation. The other, arguably more important half, is the manufacturer standing behind it. A reliable, long term equipment partner is just as critical to your project's success as the hardware itself. They provide the support and expertise that truly maximize your return on investment.

A true partner understands the practical realities of dredging operations and engineers solutions, not just products. That difference is everything, especially when downtime in a remote location can instantly turn a profitable project into a logistical nightmare. Your goal should be to find a company that acts as an extension of your own team.

Look Beyond the Spec Sheet: Engineering and Build Quality

The first sign of a top tier partner is deep engineering expertise. You want a manufacturer with a proven history of solving tough, real world problems through smart design. This is particularly crucial for specialized equipment like amphibious excavators, where stability, durability, and operator safety are not just features, they are necessities.

High quality manufacturing is another absolute must. This means they use superior materials, like high strength, corrosion resistant steel, and employ certified welders. A company committed to quality will be transparent about their processes, ensuring every component is built to survive the relentless demands of dredging work.

The Real Cost of Downtime: Support and Parts Availability

Even the toughest machine will eventually need maintenance and parts. A trustworthy partner understands that a machine sitting idle costs you money every hour. That is why a responsive, global support network is non negotiable.

Before you make a purchase, ask these important questions about their support infrastructure:

- Parts on Hand: Do they maintain a well stocked inventory of genuine replacement parts ready to ship to your location, no matter how remote?

- Technical Backup: Is there a team of seasoned technicians available to troubleshoot problems over the phone or in the field?

- Field Service: Can they dispatch skilled service professionals to your site for major repairs or scheduled maintenance to keep your equipment running optimally?

A manufacturer's true worth is proven not when everything is running smoothly, but when you encounter a problem. A partner with a robust after-sales support system and readily available parts is your best insurance policy against expensive operational delays.

A Partnership Built for the Long Haul

Ultimately, you are not just buying a machine, you are investing in a long term operational capability. The right partner offers far more than just hardware. They provide custom engineered solutions, operator training for safe and efficient use, and a genuine commitment to your success that lasts long after the sale.

The market for specialized machinery is growing, reflecting a global demand for reliable solutions. One comprehensive study projected significant growth in the dredging equipment market. This trend underscores the importance of teaming up with manufacturers who deliver durable, effective equipment backed by world class support. You can discover insights into the dredging equipment market and explore these industry trends in more detail.

At Wilco Manufacturing, we build our equipment, and our client relationships, to last. We combine deep engineering expertise with an unwavering commitment to quality and comprehensive support, ensuring your investment pays dividends for years to come.

Ready to Start Your Next Project?

Choosing the right dredging equipment is a critical decision that sets the stage for your operation's success. From understanding the different types of dredgers to pinpointing the right machine for specific challenges, you now have the insights to make an informed choice. We have seen how versatile amphibious models navigate sensitive environments and how specialized dredgers conquer massive jobs.

Now, it is time to put that knowledge into action. At Wilco Manufacturing, we do not just build heavy machinery. We engineer complete dredging solutions, tested and proven in some of the world's toughest conditions.

Your Partner in Amphibious Excellence

With decades of real world experience, we know what it takes to build equipment that performs. Our commitment to quality means you get a machine that is not just powerful, but also fundamentally reliable and safe. We understand the stakes are high, whether you are laying pipeline, reclaiming land, or restoring a natural habitat.

When you work with a seasoned manufacturer, you get more than just a piece of equipment. You get a team that truly understands the day-to-day realities of dredging. From the first conversation to long-term support, Wilco is here to help you maximize your uptime and keep your project on track.

Let's discuss your project. Our specialists are ready to dive into your unique requirements and help you find the perfect equipment solution. Whether you're looking for new dredging equipment for sale, a flexible rental, or the exact parts to keep you running, we are here to help.

Together, we will ensure your next project is a success from the ground up.

Common Questions About Buying Dredging Equipment

Investing in specialized heavy machinery like dredges always brings up a few key questions. It is a big investment, and you want to get it right. Let’s walk through some of the most common inquiries people have when they're looking at dredging equipment for sale.

How Long Will I Have to Wait for a New Dredge?

Lead times can vary significantly. If you are looking for a standard, off the shelf model, you might receive it relatively quickly. But if you need something highly customized, like a specialized amphibious excavator built for a unique environment, you are looking at a longer timeline.

Think of it like building a custom home versus buying a move in ready one. The custom build requires time for design, fabrication, and thorough testing. The best advice is to start this conversation with the manufacturer as early as possible. A good partner will be transparent about their production schedule and work with you to align it with your project's start date.

Is It Better to Buy New or Used Equipment?

The new versus used debate really comes down to your budget, project duration, and risk tolerance.

Buying new provides you with the latest technology, a full manufacturer's warranty, and the peace of mind that comes with predictable performance. For a critical, long term project, this is almost always the smarter path.

Used equipment has a lower initial purchase price, which can be tempting. But that savings can quickly be offset by surprise maintenance costs, unexpected downtime, and the lack of a warranty. When dealing with something as specialized as an amphibious excavator, choosing new from a trusted manufacturer means you are getting a machine built for your exact needs, with the support to back it up.

Choosing new equipment from an established manufacturer is an investment in reliability. You get a machine built to the highest standards, backed by support that shields your entire operation from costly delays.

What Should I Look for in After-Sales Support?

Do not overlook after sales support. Great support is the secret to keeping your equipment running and profitable. It is what separates a minor issue from a full operational shutdown.

Here is what a solid support package should include:

- Thorough Operator Training: Your team needs to operate the machine safely and efficiently.

- Readily Available Spare Parts: When something breaks, you cannot afford to wait weeks for a replacement. A well stocked parts inventory is crucial.

- Expert Technical Support: Sometimes you just need a quick answer over the phone to troubleshoot a problem.

- On-Site Field Service: For major issues or routine maintenance, you need access to technicians who can come to your job site.

A manufacturer with a strong global support network is a huge asset. It means that whether your project is in a busy port or a remote wetland, you can get the help you need, when you need it.

At Wilco Manufacturing, we don’t just build machines, we build lasting solutions and provide the rock solid support you need to succeed. Let’s talk about your next project, our specialists are ready to help you find the right fit.