Dredging is much more than moving mud from one place to another. It is about fundamentally reshaping underwater landscapes, whether for major construction projects, environmental restoration, or keeping commerce flowing. At the heart of it all is the machinery, and the success of any project comes down to choosing the right equipment for dredging. From the massive hydraulic dredges that keep our shipping channels open to nimble amphibious excavators that can navigate delicate wetlands, the right tool makes all the difference.

Why The Right Dredging Equipment Is Crucial

Picking the right equipment for dredging is not just a logistical detail, it is a strategic decision that shapes the entire project. This one choice has a direct ripple effect on your timeline, your budget, and your environmental impact. It is the cornerstone of an efficient, cost effective, and compliant operation.

Get it wrong, and you could be looking at serious delays, budgets spiraling out of control, and causing unnecessary harm to the local ecosystem.

The sheer scale of the industry highlights how vital this machinery is. The dredging equipment market is a huge piece of the marine infrastructure puzzle, valued at an estimated USD 8.9 billion in 2025 with forecasts hitting USD 14.2 billion by 2035. This is not just growth for growth's sake. It shows a clear trend toward more sophisticated and specialized equipment for everything from coastal development and waterway maintenance to critical environmental work.

Matching Equipment to Project Goals

Every dredging job has its own unique fingerprint. The material you are moving, the depth of the water, how you can access the site, and the environmental sensitivity all play a role in dictating which machine is best suited for the task. For instance, a project to clear out hard packed clay from a busy harbor needs a completely different set of tools than a project to carefully restore a shallow, marshy wetland.

Before you can make the right call, you have to weigh a few key factors:

- Material Type: What are you actually digging? Is it soft silt, dense sand, tough clay, or even rock? Mechanical dredgers are the workhorses for compacted materials, while hydraulic systems are far more efficient with loose sediment.

- Project Scale and Location: A massive, open water project might call for a trailing suction hopper dredger. On the other hand, trying to work in a swamp or marsh is practically impossible without an amphibious excavator.

- Environmental Regulations: You have to know the rules. Understanding your project's environmental footprint and staying compliant is non negotiable. A thorough Marine Environmental Impact Assessment is often the first step, and in many sensitive areas, low ground pressure equipment is a must have.

Key Takeaway: Aligning the equipment’s capabilities with the project's specific demands is the secret to a successful, efficient, and responsible outcome. This is the bedrock principle of effective project management in the dredging world.

To help simplify the landscape of dredging machinery, we can break it down into main categories. The table below gives a quick overview of the most common types, what they do best, and where you will typically find them working.

Key Dredging Equipment Types at a Glance

| Equipment Type | Primary Function | Ideal Environment |

|---|---|---|

| Mechanical Dredgers | Physically excavating and lifting material with buckets or clamshells. | Harbors, rivers, and coastal areas with compacted sand or clay. |

| Hydraulic Dredgers | Using suction and pumps to move a slurry of sediment and water. | Large scale projects in open water, channels, and sand mining. |

| Amphibious/Specialty Equipment | Operating in shallow water, wetlands, and hard to reach areas. | Environmental restoration, shoreline cleanup, and small scale projects. |

This guide is designed to be your go to resource for understanding these different types of equipment, seeing how they are used in the real world, and figuring out how to choose the best solution for your needs. With a solid grasp of the options, you can confidently select the machinery that will get the job done right, whether you are laying a pipeline or reclaiming land on a massive scale.

Exploring Mechanical Dredging Equipment

When a project demands sheer power and surgical precision, mechanical dredgers get the call. The easiest way to think of these machines is as massive underwater excavators. They physically dig into the earth, scoop up material, and lift it out.

This direct, brute force approach makes them the perfect tool for tackling hard, compacted soils or projects where accuracy is critical. Unlike their hydraulic cousins that rely on suction, mechanical dredgers use raw strength to get the job done, breaking through dense clay, removing tightly packed gravel, or clearing away large debris.

Backhoe Dredgers: The Power Diggers

At its core, a backhoe dredger is a heavy duty excavator bolted onto a sturdy, stable barge. Its powerful, articulated arm and toothed bucket can break into and remove some of the toughest materials out there, including solid rock and consolidated clay. You will often see them on jobs like port construction, harbor deepening, and digging trenches for pipelines close to shore.

The secret to the backhoe's success is its immense breakout force. It can concentrate a massive amount of pressure on a single point, cracking and loosening materials that would stop other dredgers in their tracks. This makes it an indispensable tool for projects where power and precision have to work together.

Clamshell Dredgers: The Vertical Specialists

Picture a crane armed with a giant, two sided bucket that opens and shuts just like a clamshell. That is a clamshell dredger, sometimes called a grab dredger. This setup is fantastic for digging straight down, especially in tight quarters.

They’re perfect for clearing out sediment from around bridge pilings, cleaning up tight corners in a harbor, or plucking specific obstructions from the seabed. The whole process is simple but incredibly effective:

- The open clamshell is lowered to the bottom.

- It closes, grabbing a specific volume of material.

- The crane lifts the full bucket to the surface.

- The material is dropped onto a waiting barge for transport.

This controlled, targeted removal is a game changer for environmental dredging, where you need to remove hotspots of contaminated soil without stirring everything up and making the problem worse.

Mechanical dredgers like backhoes and clamshells focus their power in a very targeted way. This gives operators unmatched control for complex underwater excavation, ensuring accuracy right where it matters most.

Bucket Ladder Dredgers: The Continuous Miners

A bucket ladder dredger is like a moving conveyor belt of buckets that digs continuously. An endless chain scoops material from the seabed, carries it up to the surface, and dumps it onto the vessel. This steady, non stop method is exceptionally good for large scale mining operations, like pulling sand, gravel, or even precious minerals from riverbeds.

While you won’t see them as often in general construction these days, their ability to excavate continuously makes them highly efficient for certain industrial jobs. They excel at maintaining a consistent dredging depth, which is critical for creating uniform channels or mining specific layers of sediment.

Amphibious Excavators: The Modern Evolution

What do you get when you combine the precision of a mechanical excavator with the ability to go almost anywhere? You get the amphibious excavator, a true leap forward in dredging technology. These machines can crawl through swamps, marshes, and shallow waterways where a traditional barge could never float.

They give you the digging power of a backhoe without needing a separate floating platform. For a closer look at this technology, you can explore the key differences between modern amphibious equipment and traditional marsh buggies. This incredible versatility makes them essential for environmental restoration, shoreline cleanup, and pipeline work in those tricky transitional zones between land and water.

Understanding Hydraulic Dredging Systems

Think of a massive, powerful vacuum cleaner, but built to work underwater. That’s hydraulic dredging in a nutshell. This approach uses high powered centrifugal pumps to suck up enormous amounts of sediment, mixing it with water to create a slurry that can be pumped miles away through a pipeline.

Unlike mechanical dredges that physically scoop material out of the water, hydraulic systems are designed for a continuous, high volume flow. They’re the go to choice for moving loose materials like sand, silt, and gravel, which makes them the perfect equipment for dredging on huge projects like land reclamation or keeping major shipping channels deep. The whole operation depends on the pump, and a good pump motor estimator is a surprisingly handy tool for figuring out the power needed for these crucial components.

Cutter Suction Dredgers: The All-Around Performers

One of the most common and versatile pieces of hydraulic gear you will see is the Cutter Suction Dredger (CSD). The business end of a CSD is its rotating cutterhead, a large, basket like tool with rugged blades, which sits at the tip of the suction pipe. As it spins, it chews through compacted or hard materials, breaking them up so they can be easily vacuumed into the pipeline.

This ability to dislodge tough sediment is what makes CSDs so incredibly versatile. They are the workhorses for a ton of different jobs, from carving out new channels in hard packed clay to mining valuable minerals from the seabed. The process is straightforward but highly effective.

- The dredger anchors itself in place using long poles called spuds, which are driven into the seabed.

- The rotating cutterhead is lowered to break apart and churn up the material.

- A powerful pump then sucks the resulting slurry up and sends it on its way through the pipeline.

Because a CSD can handle just about anything from soft mud to dense rock, it is often the first choice for harbor expansions, land reclamation, and big environmental cleanups where you just need to move a lot of material fast.

The real magic of the CSD is its one two punch of mechanical cutting and hydraulic suction. It can chew through a much wider range of materials than a simple suction dredge, making it one of the most adaptable pieces of dredging equipment on the market.

Trailing Suction Hopper Dredgers: The Marine Vacuums

If the CSD is a stationary powerhouse, think of the Trailing Suction Hopper Dredger (TSHD) as its mobile cousin. A TSHD is essentially a self propelled ship that acts like a giant vacuum cleaner, sucking up sediment while it moves. It drags one or two long suction pipes, called drag arms, along the bottom, collecting loose material as it goes.

All that dredged slurry gets stored in a massive internal compartment known as a hopper. Once the hopper is full, the TSHD sails over to a designated spot to unload. The material can either be dropped through doors in the bottom of the hull or pumped out to nourish a beach or build up new land.

This constant, on the move operation makes TSHDs the undisputed champions of large scale maintenance. They are absolutely critical for keeping the world's busiest shipping lanes clear for container ships and tankers, ensuring global trade does not grind to a halt. For projects that need more precision in sensitive, shallow areas, a specialized amphibious dredge unit can provide a more nimble alternative.

The Advantage Of Amphibious Excavators

So much of today's dredging work happens in those tricky transition zones where solid ground gives way to water. Think swamps, marshes, flimsy shorelines, and floodplains. For traditional equipment, these areas are a nightmare. A land based excavator is too heavy and will sink, while a barge mounted dredger cannot get into the shallow spots. This is exactly the kind of environment where an amphibious excavator does not just work, it excels.

These machines are far more than just a standard excavator slapped onto a set of pontoons. They are engineered from the ground up as a single, cohesive piece of equipment for dredging. The design masterfully blends the raw digging power of a mechanical excavator with the go anywhere mobility of a specialized amphibious undercarriage. This combination lets one machine crawl from dry land, through thick mud, and right into the water, all on its own.

Unlocking Unprecedented Versatility

The real magic of an amphibious excavator is its sheer versatility. Imagine a typical wetland restoration project. To get the job done conventionally, you would need to bring in a whole fleet: barges, land based excavators, maybe even tugboats. The logistics alone are a headache, not to mention the cost, time, and environmental disturbance of moving all that iron into place.

An amphibious excavator changes the entire game. It can often tackle the whole job single handedly. It simply walks itself to the work site, performs the precise digging or material handling required, and then moves on to the next spot under its own power. This self sufficiency completely eliminates the need for a circus of support equipment, which dramatically cuts down on mobilization time and operational costs.

The true advantage is efficiency. By replacing a fleet of specialized machines with a single, highly mobile unit, amphibious excavators simplify project management, cut costs, and minimize site disruption, especially in environmentally sensitive areas.

Excelling In Critical Applications

This unique design makes amphibious equipment the go to choice for a whole range of tough projects where other machines just can’t get the job done. This adaptability is why we are seeing them pop up in more industries and why the market is growing so quickly.

The global demand for flexible dredging solutions is definitely on an upward trend. The Asia Pacific region is a great example, where massive infrastructure and urbanization projects are fueling the fastest market growth. In fact, market studies project the dredging equipment market will grow at a CAGR of around 6.7% between 2025 and 2032. That is an expansion from USD 4.75 billion in 2024 to an expected USD 7.96 billion by 2032. As more work moves into complex terrains, you can bet amphibious technology will be a major driver of that growth. You can explore more about these market projections and the forces behind them by reading further analysis on the dredging equipment market.

So, where do these machines really shine? Here are a few key applications:

- Environmental Cleanup: The pontoons distribute the machine’s weight, resulting in very low ground pressure. This is perfect for working in delicate ecosystems like wetlands, allowing for the surgical removal of contaminated sediment without destroying the surrounding habitat.

- Pipeline Installation and Maintenance: Pipelines often run through swamps and marshlands. An amphibious excavator can easily navigate these areas to dig trenches and provide support, without the need to build access roads or bring in barges.

- Disaster Recovery: After a flood, these machines are invaluable. They can get into washed out areas to clear debris, rebuild levees, and restore waterways long before conventional heavy equipment could ever reach the site.

- Land Reclamation and Coastal Restoration: They are incredibly effective at moving sand and sediment in shallow coastal zones, helping to build up shorelines, create new wetlands, and fight erosion.

To really appreciate the difference, it helps to see a side by side comparison of how these machines stack up against a more traditional setup for wetland or shoreline work.

Comparing Conventional vs Amphibious Equipment

| Feature | Conventional Dredger Setup | Amphibious Excavator |

|---|---|---|

| Mobilization | Complex and slow; requires barges, tugs, and land based support equipment. | Simple and fast; machine can walk itself to the worksite under its own power. |

| Site Access | Limited by water depth and ground stability; needs access roads or navigable water. | Can traverse land, mud, swamps, and shallow water seamlessly. |

| Operational Footprint | Large; requires multiple machines, extensive laydown areas, and logistical support. | Small; a single, self sufficient machine handles most tasks. |

| Environmental Impact | Higher risk of habitat damage from multiple machines and extensive site prep. | Minimal ground pressure and site disruption, ideal for sensitive areas. |

| Efficiency | Lower; significant time spent on setup, teardown, and coordinating different machines. | High; reduces downtime and streamlines the entire workflow from start to finish. |

As you can see, the amphibious excavator offers a far more agile and efficient approach, especially when the worksite is anything but a simple, open body of water.

A Smarter, More Agile Approach

Ultimately, the growing popularity of the amphibious excavator signals a shift in the industry toward smarter, more adaptable, and environmentally responsible dredging. By packing mobility, power, and a light touch into a single machine, it offers a nimble and powerful solution for the world's most challenging jobsites. You can learn more about how a state of the art amphibious excavator from Wilco can solve these specific project challenges. This is not just another piece of equipment; it’s a whole new way of thinking about how to work where land and water meet.

How to Select the Right Dredging Equipment

Picking the right piece of dredging equipment is not just a logistical choice, it is a critical decision that can make or break your project's timeline, budget, and overall success. The wrong machine leads to costly delays and headaches, while the right one ensures a smooth, efficient operation from day one. Let's walk through how seasoned project managers and engineers approach this decision.

The key is to be systematic. When you methodically weigh your project’s unique demands against the capabilities of different machines, you can select the most effective equipment with confidence and get the job done right.

Analyze Your Project’s Core Requirements

Before you even think about specific models, you need to do a deep dive into the project environment and your core objectives. Every site has its own personality, and understanding its quirks is non negotiable.

Here are the big questions you need to answer:

- What kind of material are you moving? The makeup of the sediment is everything. If you are dealing with soft silts and loose sands, a hydraulic system is your best bet. But for compacted clays, dense gravel, or rock, you will need the raw breakout force of a mechanical dredger.

- What are the site and water conditions? Are you working in a deep, open channel or a shallow, cramped wetland? A Trailing Suction Hopper Dredger might be perfect for deep water, but it is useless in a swamp where only an amphibious excavator can go.

- What is the scale of the project? How much material do you need to move, and how far does it need to go? Massive land reclamation jobs often call for a high volume Cutter Suction Dredger, whereas smaller, targeted environmental cleanups are better handled with more precise mechanical gear.

- What do the environmental regulations say? Strict rules can seriously limit your options. Projects in sensitive ecosystems often demand low ground pressure machines to protect the habitat and keep turbidity to a minimum.

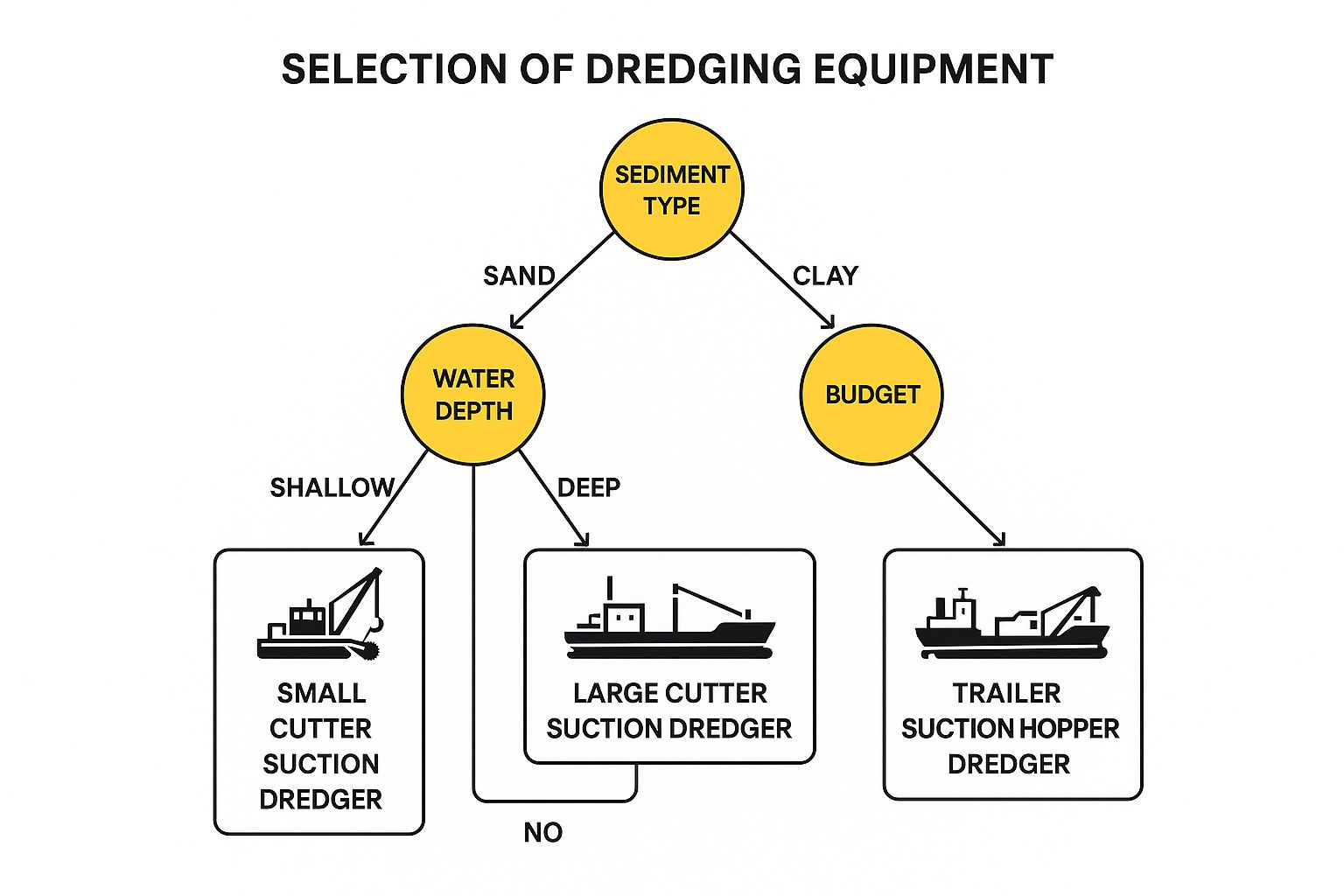

This decision tree gives you a good visual of how these factors guide you toward the right equipment, zeroing in on sediment type, water depth, and budget.

As you can see, just a few key decisions can quickly narrow the field and point you to the best class of equipment for your job.

Matching Equipment to Material

The type of sediment you’re dredging is almost always the deciding factor. Mechanical dredgers, like backhoes and clamshells, work by physically digging and lifting material. This makes them the clear winner for tough, consolidated soils where you need direct force to break it apart.

On the other hand, hydraulic dredgers are champions of efficiency when you’re moving huge volumes of loose stuff like sand and silt. By creating a continuous slurry flow, they make quick work of maintenance dredging and large scale sand mining operations.

Think of it as a balancing act between power and finesse. You are trying to match the machine's core strength, whether it is the brute cutting force of a CSD or the surgical precision of a clamshell, to the unique geological and logistical puzzle your site presents.

Considering Long-Term Operational Costs

The sticker price is just the beginning. You have to think about the total cost of ownership, which includes everything from fuel consumption and crew size to mobilization and demobilization expenses. For instance, a massive hydraulic dredger is incredibly efficient, but its daily operating costs are sky high.

For projects in remote or tricky locations, versatile machines like amphibious excavators can dramatically cut down on logistical costs and improve project ROI.

The stakes are getting higher, too. In 2024, the global dredging market was valued at USD 12.84 billion and is expected to climb to USD 15.89 billion by 2029, growing at a CAGR of 4.6%. This growth is fueled by everything from port expansions to coastal restoration, which just goes to show how diverse and financially significant this work is.

To get the most out of your investment, it is crucial to implement effective preventive maintenance strategies. A well maintained machine does not just perform better, it holds its value and keeps your project running without a hitch.

Finding the Right Partner for Your Dredging Project

Picking the right dredging equipment is arguably the single most important decision you will make for your project. As we have covered, you have options, from the sheer power of mechanical dredgers for tough, compacted ground to the high volume output of hydraulic systems and the go anywhere versatility of amphibious excavators.

Knowing the difference is a great start. But the final piece of the puzzle is finding a partner who can help you apply that knowledge in the real world, turning specs on a page into a practical, effective solution on your job site. This is where experience really counts.

A genuine partner does more than just sell or rent you a machine. They bring to the table a deep understanding of the unique challenges that come with different environments, whether it’s laying a pipeline through a sensitive wetland or executing a massive land reclamation project.

It Is About More Than Just the Machine

A successful project hinges on having a partner who offers comprehensive support. This means they not only provide top tier amphibious equipment but also bring the industry wisdom needed to pair the right machine with your project's specific demands.

Think of them as an extension of your own team. They are there to make sure you have the right tools and the right support from day one until the job is done.

This kind of partnership typically includes:

- Tailored Equipment Solutions: Engineering a machine configuration specifically for the material, depth, and environmental factors of your site.

- Flexible Rental Plans: Giving you access to specialized gear for one off or short term jobs without a huge capital outlay.

- Dependable Parts and Service: Keeping your operation running smoothly with a solid supply of parts and expert maintenance to minimize any costly downtime.

A successful dredging operation is not just about having the best gear; it is about deploying it correctly. The best results come from combining innovative equipment with the seasoned expertise to ensure every phase of the project is efficient, safe, and compliant.

When you work with a manufacturer that has a proven track record, you are not just buying a piece of equipment, you are gaining an ally. You get access to a team of people who are invested in your success.

At Wilco Manufacturing, we fill that role, providing not just the equipment for dredging but the hands on expertise to make sure it delivers. This partnership approach helps you take everything you have learned in this guide and put it into action.

Ready to set your next project up for success? Contact Wilco Manufacturing to talk through your dredging needs and find the perfect amphibious solution.

Your Dredging Equipment Questions, Answered

Even when you know the different types of dredging gear inside and out, the practical side of planning a project always brings up new questions. Getting these common issues sorted out beforehand can be the difference between a smooth operation and a project full of headaches.

Let's dive into some of the questions we hear most often from the field.

What’s Involved in Maintaining a Dredging Pump?

Think of the dredge pump as the heart of your hydraulic system. If it goes down, everything stops. That’s why consistent maintenance is non negotiable, it is your best defense against expensive, project killing downtime. Most of the work revolves around the parts that take a constant beating from abrasive slurries.

Here’s what a good maintenance routine looks like:

- Impeller Inspection: Get your eyes on the impeller regularly. You are looking for wear, any signs of cracking, or imbalance. A worn out impeller does not just work less efficiently; it can also create vibrations that wreck the whole pump.

- Seal Checks: Seals are your first line of defense against leaks. Once a seal fails, you are on the fast track to bearing failure and much bigger problems. Inspect them, and do not hesitate to replace them.

- Wear Plate Adjustments: Inside the pump casing, wear plates take the brunt of the abrasion. You have to keep an eye on them and adjust as needed to maintain the tight clearances required for peak performance.

- Lubrication: This one is simple but crucial. Proper lubrication for the bearings cuts down on friction and heat, which is key to making the pump last.

A proactive schedule is always better than a reactive repair. Stay ahead of problems, and you will keep your project moving.

How Do Amphibious Excavators Actually Protect the Environment?

This is a great question. Amphibious excavators are designed from the ground up to work in sensitive areas with a light touch, making them a go to for environmental jobs.

The real magic behind an amphibious excavator’s low environmental impact is its incredibly low ground pressure. By spreading its weight across those massive pontoons, it can move across marshland and soft soils without sinking in, tearing up the ground, or destroying delicate plant root systems.

This fundamentally different design minimizes the project’s footprint in a few key ways:

- You often do not need to build access roads or dredge channels just to get a barge into the work area. The machine walks itself in.

- It allows for a more surgical approach, letting you remove contaminated sediment or invasive species with minimal collateral damage.

- It stirs up far less sediment and reduces water turbidity compared to larger, clumsier dredging methods.

Is It Possible to Rent Dredging Equipment for Shorter Jobs?

Absolutely. Renting equipment for dredging is not just possible, it’s often the smartest move, especially for companies that don’t live and breathe dredging every day. It gives you access to specialized, expensive machinery for a single project without the massive capital outlay of buying it.

Renting is a perfect fit for short term or one off projects, like cleaning out a small marina or handling a seasonal cattail removal project. Plus, you get the benefit of using the latest and greatest tech, and it comes with expert support from the rental company. They make sure the machine is right for your job, perfectly maintained, and ready to work the moment it arrives on site.

Partnering with an expert in amphibious equipment ensures you have the right machine and the right support for your unique project challenges. At Wilco Manufacturing, we provide customized solutions, rentals, and parts to ensure you are fully equipped for success. Learn more about how Wilco Manufacturing can support your next project.