A powerful hydraulic pump excavator system is the heart of any heavy machinery, converting engine power into the force needed to move tons of material. Its health and efficiency directly dictate project speed, fuel consumption, and overall equipment longevity. Understanding this core component is the first step toward optimizing performance and avoiding costly downtime on the job site.

The Heart of Excavator Performance

At its core, the hydraulic pump breathes life into an excavator. You can think of it as the machine's heart. While the engine provides raw energy, the pump takes that mechanical power and converts it into pressurized hydraulic fluid, the lifeblood of the entire system.

This pressurized fluid is then channeled through a complex network of hoses and valves to power every single movement. From the massive sweep of the boom to the precise curl of the bucket, each action is a direct result of the pump's tireless work. Without an effective pump, all that engine power would just be noise and heat.

Translating Power into Productivity

The pump’s primary job is to generate hydraulic flow and pressure. These two factors work hand in hand to control the machine's capabilities. Here’s a simple way to break it down:

-

Pressure controls power. This is the raw muscle of the excavator. Higher pressure allows the machine to exert more force, which is absolutely critical for breaking tough ground, lifting heavy loads, or using powerful attachments like hydraulic breakers.

-

Flow controls speed. This dictates how quickly the hydraulic fluid moves through the system, which translates directly to the speed of the boom, arm, and bucket. More flow means faster cycle times, letting operators move more material in less time.

A top tier hydraulic pump excavator strikes the perfect balance between these two, delivering both the brute force for demanding tasks and the quickness needed for efficient operation.

Hydraulic Pump Functions at a Glance

The table below breaks down these core functions and their real world impact on the job site.

| Function | Impact on Excavator Performance | Real-World Example |

|---|---|---|

| Generates Hydraulic Flow | Controls the speed of all moving parts (boom, arm, bucket, tracks). | Higher flow enables faster trenching or loading trucks, directly boosting productivity. |

| Creates Hydraulic Pressure | Determines the machine's lifting and breakout force. | Sufficient pressure is needed to break through rock or lift a heavy concrete pipe. |

| Converts Mechanical Power | Transforms the engine's rotational energy into hydraulic energy. | This is the fundamental energy transfer that makes any hydraulic action possible. |

| Powers Attachments | Provides the necessary flow and pressure for hydraulic tools. | Running a hydraulic hammer or a mulching head requires consistent and powerful output from the pump. |

Ultimately, a well maintained pump ensures every function works in sync, turning a massive piece of steel into a precise and powerful tool.

Why Pump Performance Matters in Demanding Environments

When you move into specialized applications, like those involving amphibious excavators, the demands on the hydraulic system skyrocket. Operating in wetlands, swamps, or dredging sites means the equipment is constantly battling water, thick mud, and corrosive elements.

A robust and reliable hydraulic pump is non negotiable in these conditions. Its ability to consistently deliver optimal pressure and flow ensures that the amphibious undercarriage has the power to navigate treacherous terrain while the excavator continues its work without missing a beat.

This is where Wilco Manufacturing's expertise comes into play. By integrating powerful and durable hydraulic systems into our amphibious equipment, we ensure our clients have machinery that performs reliably in the world's toughest environments. A strong hydraulic heart is the key to conquering complex projects, from pipeline installation in marshlands to environmental cleanup in sensitive coastal areas.

Exploring Different Types of Hydraulic Pumps

While every hydraulic pump does the same basic job, moving fluid to create force, they are definitely not all created equal. The technology humming away inside a hydraulic pump excavator can vary wildly, with each design striking a different balance between performance, durability, and cost.

Understanding these differences is the key to recognizing why engineers choose specific pumps for certain jobs, from routine digging to the grueling work of an amphibious machine. The three main players you will find in heavy equipment are gear, vane, and piston pumps. Let's dig into how each one gets the job done and where it fits in.

Gear Pumps: The Simple Workhorse

Gear pumps are about as straightforward as it gets. Imagine two gears meshing together. As they spin, they trap hydraulic fluid in the gaps between their teeth, carrying it from the pump’s inlet to the outlet. It’s a beautifully simple and effective mechanism.

Because they have so few moving parts, gear pumps are incredibly rugged, reliable, and easy on the wallet. They are also less sensitive to fluid contamination, which is a huge plus on a muddy, dusty job site. The trade off? They are generally less efficient and cannot produce the high pressures of their more complex cousins. This makes them a great fit for smaller machines or for running auxiliary systems.

Vane Pumps: The Balanced Performer

Sitting comfortably in the middle ground, you will find the vane pump. It strikes a nice balance between the simplicity of a gear pump and the high performance of a piston pump. Inside, a rotor with slots spins off center within a circular housing. Small vanes slide in and out of those slots, trapping fluid and pushing it toward the outlet.

The result is a pump that runs quietly and delivers good efficiency at moderate pressures. You’ll often find them in mid sized excavators where the goal is solid performance without the higher cost and complexity of a top tier system. They are a step up from gear pumps and offer a great all around hydraulic solution.

The global market for excavator hydraulic pumps is a big one, valued at around USD 9.73 billion in 2022 and expected to climb to USD 14.93 billion by 2030. This growth shows just how vital these components are across the construction and excavation industries. Even with more advanced options available, the trusty gear pump still holds a major market share thanks to its unbeatable reliability in certain applications.

Piston Pumps: The High-Pressure Specialist

When a job demands serious muscle and precision, the piston pump is the undisputed champion. This is the top tier technology you will find in most modern, high performance excavators. Just like the pistons in a car engine, a series of reciprocating pistons draw in fluid and then force it out under immense pressure.

This design is what allows an excavator to perform incredible feats of strength, digging through tough ground, lifting heavy materials, and powering massive attachments. The power and control they offer are simply on another level.

For specialized machines like the ones we build at Wilco, there is really no other option. Piston pumps are non negotiable for a few key reasons:

- Unmatched Power: They generate the raw force needed to push an amphibious excavator through the thickest mud and swamps.

- Superior Control: Their variable displacement design allows the operator to fine tune the hydraulic flow, making for incredibly smooth and precise movements, even when operating multiple functions at once.

- High Efficiency: These pumps are masters at turning engine horsepower into hydraulic power. This means better fuel economy and lower operating costs over the life of the machine.

Sure, they are the most complex and expensive of the bunch, but for the toughest jobs on earth, the performance of a piston pump is the only thing that will do. They ensure a machine is ready for absolutely any challenge thrown its way.

How to Select the Right Hydraulic Pump

Choosing the right hydraulic pump for your excavator is not just about matching a part number from a catalog. It's a decision that echoes through every aspect of your project, impacting efficiency, fuel burn, and the machine's overall lifespan. To get it right, you have to look past the spec sheet and understand how those numbers translate to actual performance out in the field.

Think of it as finding the right balance between power, speed, and endurance. You are not just considering the demands of the excavator itself, but also the gritty reality of the environment it works in. This is especially true for amphibious equipment, which faces a unique onslaught of stressors like constant water exposure and abrasive muck.

Core Performance Metrics that Matter

When you are comparing hydraulic pumps, three key specs tell you most of what you need to know: pressure rating, flow rate, and displacement. Get a handle on these, and you are well on your way to making a smart choice.

-

Pressure Rating (PSI or Bar): This is the pump's raw muscle. It dictates the maximum force the hydraulic system can deliver, which is absolutely critical for breaking through tough ground, lifting heavy loads, or running high powered attachments. A pump with a weak pressure rating means your machine will bog down or stall when you need it most.

-

Flow Rate (GPM or L/min): If pressure is muscle, flow is speed. This metric tells you how much hydraulic fluid the pump can move over a certain amount of time. A higher flow rate means faster cycle times, the boom, arm, and bucket all move quicker. For high volume jobs like dredging or mass earthmoving, a high flow rate is essential for keeping the project on schedule.

-

Displacement: This one is a bit more technical. It refers to the volume of fluid the pump moves with each single rotation. It is a fixed design characteristic, but it’s a crucial piece of the puzzle for calculating the pump's total output and efficiency.

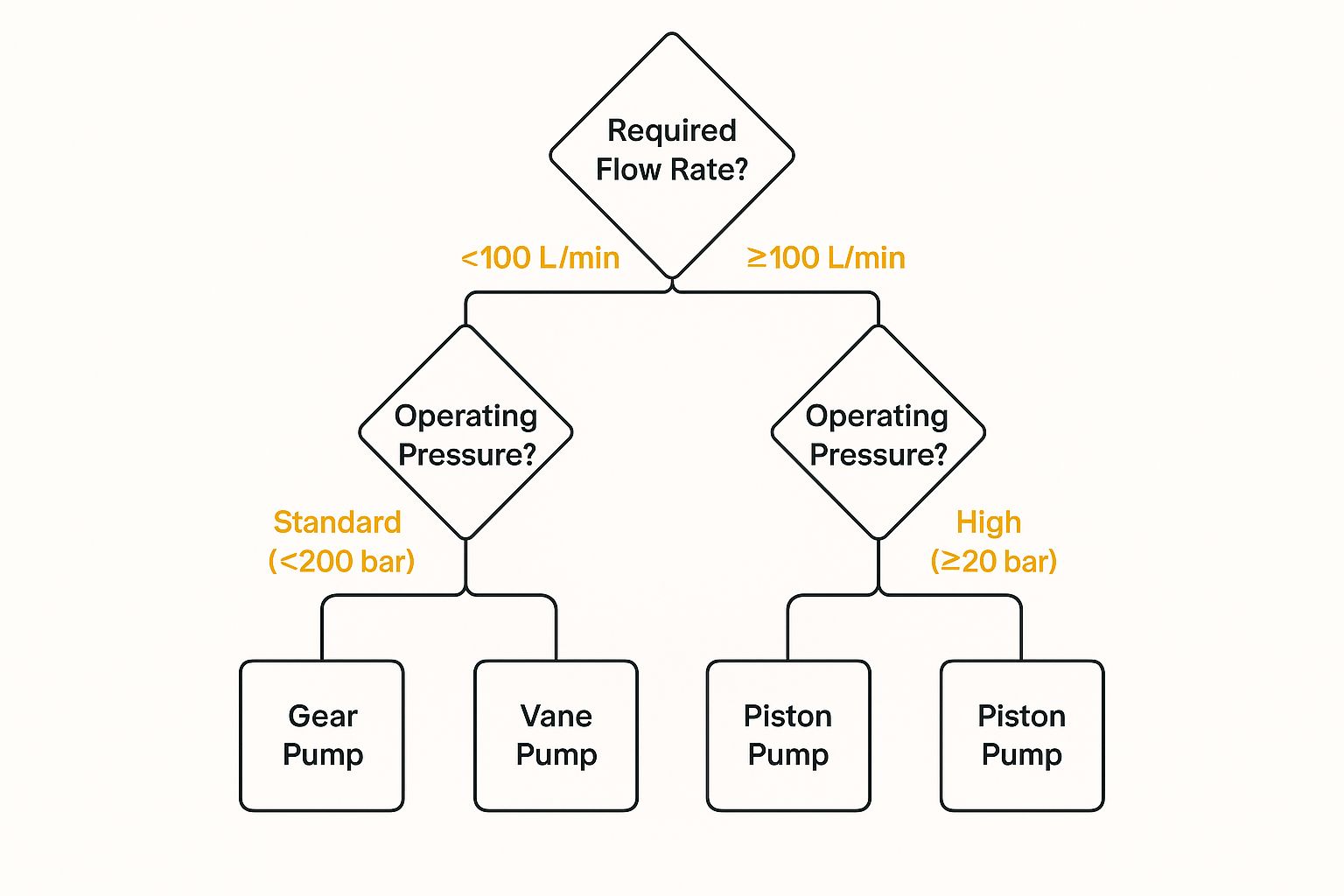

This simple decision tree helps visualize how these factors point you toward the right type of pump for the job.

As you can see, the high pressure, high flow demands of most modern heavy excavators almost always lead to the sophisticated power of a piston pump.

Pump Selection Criteria Comparison

To help clarify the decision making process, this table breaks down how different project needs align with the capabilities of gear and piston pumps, with a special focus on the tough requirements of amphibious work.

| Selection Factor | Gear Pump Suitability | Piston Pump Suitability | Key Consideration for Amphibious Use |

|---|---|---|---|

| Pressure Requirements | Best for low to medium pressure applications. | Excellent for high pressure, heavy duty tasks. | Amphibious excavators need high pressure to move through mud and power attachments. Piston pumps are the clear winner. |

| Flow & Speed Needs | Provides a fixed, constant flow rate. | Offers variable flow for precise speed control. | The ability to vary flow is crucial for navigating and working simultaneously. Variable flow is a must have. |

| Operational Efficiency | Generally less efficient, especially at high pressures. | Highly efficient, converting more engine power into work. | Fuel efficiency and power are paramount. The higher efficiency of piston pumps reduces operational costs. |

| Cost & Complexity | Lower initial cost and simpler design. | Higher initial cost and more complex construction. | While the upfront cost is higher, the reliability and performance of a piston pump prevent costly downtime. |

| Durability & Environment | Susceptible to wear from contamination. | More robust and better sealed against contaminants. | The pump must withstand water, silt, and debris. Enhanced durability and sealing are non negotiable. |

Ultimately, the table underscores why robust, high performance piston pumps are the standard for specialized equipment operating in harsh environments.

Matching the Pump to the Application

The best pump is always the one that’s right for the job at hand. A standard excavator on a construction site might work just fine with a pump balanced for everyday digging. But take that same machine, mount it on an amphibious undercarriage, and send it into a swamp, suddenly, the demands are worlds apart.

For amphibious operations, pump selection must prioritize reliability and durability above all else. The system needs to withstand continuous operation in waterlogged environments, resist corrosion from sediment and moisture, and deliver consistent power to navigate through thick mud while simultaneously performing excavation work.

This is exactly why high performance piston pumps have become the go to for specialized machines. They deliver the high pressure and variable flow needed to generate raw power in tough conditions while also providing the fine tuned control required for complex tasks. A lesser pump would simply buckle under that kind of relentless strain.

Beyond the Numbers: Reliability and Support

Finally, do not forget the factors that are not on the spec sheet. The manufacturer's reputation, the availability of spare parts, and the quality of their technical support are just as important. A pump that’s hard to service or has a six week lead time on parts can turn a small hiccup into a major project stopping headache.

At Wilco Manufacturing, we specifically choose hydraulic components that have proven their mettle in the world’s most demanding environments. By building our amphibious systems with robust and reliable hydraulic pumps, we make sure our clients get equipment that delivers maximum uptime and productivity, no matter how tough the job gets. That commitment to quality is how you build machinery you can truly depend on.

Essential Hydraulic Pump Maintenance Practices

When it comes to your hydraulic pump excavator system, an ounce of prevention is truly worth a pound of cure. Proactive care is always cheaper than reactive repairs, and a consistent maintenance schedule is your best bet for keeping the pump, the heart of your machine, running strong for its entire service life.

This is not just about fixing things when they break. It’s a disciplined routine of daily checks, fluid analysis, and inspections designed to spot small issues before they snowball into catastrophic failures. For owners and operators, this translates directly to more uptime, lower operating costs, and a safer job site.

Creating a Proactive Maintenance Schedule

A solid maintenance plan is built around a calendar of regular tasks. How often you perform these checks will depend on the machine's age, how many hours it's running, and the kind of work it's doing. Still, a good baseline schedule gives you the structure you need to keep your hydraulic system in top shape.

Here’s a practical look at what that schedule should include:

-

Daily Pre-Operation Checks: Before firing up the machine, the operator should do a quick walk around. Look for any tell tale signs of fluid leaks around the pump, hoses, and fittings. It is also smart to listen for any strange noises like whining or grinding during warm up, these are often the first signs of a pump in distress.

-

Regular Fluid Analysis: The hydraulic fluid is the lifeblood of your system. Sending a small sample to a lab every 250-500 operating hours can tell you a story about what’s happening on the inside. The analysis spots contaminants like water, dirt, and tiny metal particles, giving you a heads up about pump wear long before it fails.

-

Scheduled Filter Replacement: Hydraulic filters are your system's kidneys, constantly cleaning the fluid. Following the manufacturer's replacement schedule, usually around every 500 hours, is not optional. A clogged filter can starve the pump for fluid, which leads to cavitation and serious internal damage.

The Critical Role of Clean Hydraulic Fluid

Knowing why you are doing these tasks makes it easier to stick with them. The number one enemy of any hydraulic pump is contaminated fluid. Once dirt, water, or metal shavings get into the system, your hydraulic oil essentially becomes liquid sandpaper.

This abrasive sludge starts grinding away at the pump's internal components, which are built with incredibly tight tolerances. The result? Premature wear, lost efficiency, and eventually, total failure. A single speck of dirt, too small to see, can score a piston or jam a valve, starting a domino effect of damage throughout the system.

Preventing contamination is always more effective than trying to remove it. By prioritizing clean fluid, regular filter changes, and proper fluid handling, you are directly protecting your most valuable hydraulic components from accelerated wear and tear.

This level of care becomes even more crucial in tough environments. When an excavator is working in mud, sand, or water, the risk of contaminants getting into the hydraulic system skyrockets. This is a constant battle for amphibious equipment, where the machinery is always exposed to the elements. For operators running specialized gear like an amphibious dredge unit, a heightened sense of awareness and more frequent checks are absolutely necessary to fight off these harsh conditions and ensure the machine stays reliable.

Adapting Maintenance for Harsh Conditions

The standard maintenance intervals you see in the manual are for typical working conditions. But amphibious and severe duty jobs are anything but typical. The constant exposure to water, silt, and corrosive materials calls for a much more aggressive maintenance plan.

Operators in these environments should seriously consider shortening their service intervals. For example, you might need to run a fluid analysis every 250 hours instead of 500. Daily inspections need to be more thorough, with a close eye on the seals and fittings most likely to let in water and debris. This flexible, adaptive approach ensures your hydraulic system is shielded from the unique challenges of demanding sites, protecting your investment and keeping the project on track.

Troubleshooting Common Hydraulic Pump Issues

Even the best maintained excavator hydraulic pump will eventually start showing its age. These machines work hard, and wear is inevitable. The trick is to catch the problems early. Learning to spot the warning signs and understand what they mean gives you the power to act quickly, turning a potential disaster into a minor hiccup.

This is not about trying to become a master mechanic overnight. It’s about building your gut instinct for what sounds and feels right with your equipment. When you can spot trouble brewing, you can talk intelligently with your technicians and make smart calls on repairs, protecting your investment and keeping the job on schedule.

Identifying Common Symptoms and Their Causes

Most pump problems do not just happen out of the blue. They send out signals first. Each one is a clue, a piece of the puzzle that points to what’s going wrong under the hood. Knowing how to read these signs is the first step to figuring out the real issue.

Here are the most common red flags and what they’re likely telling you:

- Noticeable Loss of Power: Is the machine suddenly struggling with loads it used to lift with ease? Can it no longer dig into hard ground like it once did? This often means the pump is not building enough pressure. It could be anything from simple internal wear to a bad pressure relief valve or a hidden leak.

- Slow or Sluggish Operation: When your cycle times start dragging and every movement feels like it’s in slow motion, you’re probably looking at a flow problem. A worn out pump might not be moving enough oil, or maybe a clogged filter is starving the system. You could even have air in the hydraulic fluid, making it foamy and inefficient.

- Excessive Noise: A happy hydraulic system is a relatively quiet one. If you suddenly hear loud whining, grinding, or knocking, stop and listen. A high pitched whine often points to cavitation, the pump is struggling to pull in enough fluid. Grinding sounds are more serious; they can signal major internal damage or debris circulating in the system.

- Overheating: If your system is constantly running hot, it is a clear sign of stress. An overheating pump might be working too hard to compensate for a problem elsewhere. It could also be caused by something as simple as low fluid levels, a dirty oil cooler, or even using the wrong type of hydraulic fluid for the season.

A Logical Diagnostic Process

When a symptom pops up, it is easy to immediately blame the pump. But hold on. The hydraulic system is a complex network, and a problem in one spot can easily look like a pump failure. A clogged filter, for example, can cause both power loss and overheating, two classic signs people attribute to a bad pump.

The first rule of troubleshooting is always to check the simple stuff first. Before you assume the worst, look at the hydraulic fluid level and its condition. Check your filters. Do a quick walkaround to look for any obvious leaks. You’d be surprised how many “major” problems are solved with these basic checks.

If the basics are all good, then it is time to dig deeper and isolate the issue. This is where a technician will break out the flow meters and pressure gauges to test the pump's actual output. This data driven approach takes the guesswork out of the equation. It tells you for sure if the pump is underperforming or if the problem is with another part, like a relief valve or a specific cylinder.

For machines working in tough spots, like amphibious marsh buggies, knowing these steps is critical to staying operational. You can see how these unique machines differ in our guide on Hydratrek vs. traditional marsh buggies.

The good news is that manufacturers are always making pumps tougher. Modern designs are more energy efficient and include systems to absorb hydraulic shocks, which helps them last longer and waste less energy. This focus on durability helps tackle concerns about both equipment lifespan and fuel consumption, a trend explored in this hydraulic pump market analysis. When you combine these better, stronger components with a smart troubleshooting approach, you can get the absolute most out of your excavator's hydraulic system.

The Future of Hydraulic Pump Technology

The story of the hydraulic pump is one of relentless innovation. We’ve watched them evolve from simple, fixed displacement units into the incredibly advanced, electronically controlled powerhouses at the heart of modern excavators. This journey has been the driving force behind massive gains in performance, huge drops in fuel consumption, and a level of operator control we could only dream of a few decades ago. Now, we’re on the cusp of another leap forward that will redefine what heavy machinery can do.

If you look at the history of the pumps inside a hydraulic pump excavator, you see a clear upward trajectory. The shift from fixed to variable displacement pumps was a game changer, giving us the ability to precisely manage fluid flow. That single change led directly to better fuel economy and more productive machines. For a deeper dive into how the industry adopted these technologies, Grandview Research offers some great market insights.

And that momentum is only building. The next generation of pumps is shaping up to be smarter, more efficient, and more connected than ever.

The Rise of Digital Integration

One of the biggest shifts we are seeing is the tight integration of digital controls right into the pump itself. Today’s excavators are packed with sophisticated electronics that constantly read operator inputs and sense the machine's workload. The pump then reacts instantly, delivering the precise flow and pressure required for the job, and not a drop more.

This kind of smart system brings some serious advantages to the table:

- Optimized Fuel Efficiency: By perfectly matching hydraulic power to the immediate task, these pumps cut out wasted energy. The result is real, measurable fuel savings.

- Enhanced Operator Control: For the person in the cab, the machine feels smoother and more responsive. This makes delicate work like fine grading or complex lifts much easier and more precise.

- Automated Functions: Digital controls are the foundation for automated features like grade control and pre set digging cycles, which help boost productivity and ensure consistent results day after day.

Predictive Maintenance and Onboard Diagnostics

Another huge step forward is embedding sensors directly within the pump and the broader hydraulic system. Think of them as a 24/7 early warning system, constantly monitoring vitals like fluid temperature, pressure fluctuations, and vibration patterns. All this data creates a real time health check on the pump.

Instead of waiting for something to break, predictive maintenance lets fleet managers spot trouble early and schedule repairs during planned downtime. This data first approach virtually eliminates those surprise, project stopping failures and helps squeeze more life out of the equipment.

This technology is a lifesaver for specialized equipment, especially machines working in tough environments. For excavators fitted with amphibious hydraulic undercarriages, a breakdown in a swamp or waterway is not just an inconvenience, it's a massive, costly problem.

A Focus on Energy Efficiency and Sustainability

As the entire industry pushes for more sustainable operations, pump manufacturers are laser focused on designing components that deliver more punch with less power. We are seeing exciting innovations in materials science, smarter internal designs, and more refined electronic management, all aimed at boosting overall efficiency. Looking ahead, expect to see more energy recovery systems, where the power from one hydraulic movement (like lowering the boom) is captured and reused for another. These advancements are building a future where excavators are not only more powerful and precise, but also much better for the bottom line and the environment.

Frequently Asked Questions

Even after you have a good handle on the ins and outs of an excavator's hydraulic pump, a few specific questions always seem to pop up. Getting these details straight is key to making smart, confident decisions about your equipment. Let's tackle some of the most common questions we get from owners and operators in the field.

How Often Should I Replace My Excavator Hydraulic Pump?

There is no hard and fast rule here, no magic number of hours on the clock. A pump's lifespan really comes down to how it is used, how well it is maintained, and, most importantly, how clean you keep the hydraulic fluid. Forget the calendar; you need to watch its performance.

It is probably time for a replacement when you notice these tell tale signs:

- A major, lasting drop in hydraulic pressure or a machine that feels sluggish.

- The system is constantly overheating, and you have already tried other fixes.

- A fluid analysis report shows significant internal leakage or metal shavings.

And if your machine is working in tough conditions, like an amphibious excavator churning through silt and water, you need to be even more vigilant. More frequent inspections are a must to spot wear and tear before it becomes a full blown failure.

What Is an Open-Loop vs Closed-Loop Hydraulic System?

This is all about how the hydraulic fluid gets around. Think of an open loop system as a circular route with a rest stop. Fluid gets pulled from the reservoir, goes to power the boom, arm, and bucket, and then heads back to the reservoir to cool down and get filtered before starting the trip again. It is the go to design for most excavator functions because it’s simple and reliable.

A closed loop system is more like a direct shuttle service. The fluid travels directly from the pump to a hydraulic motor and back, which is perfect for an excavator's travel drives. This setup is incredibly efficient for jobs that need constant high torque, like moving the machine forward. The catch? The fluid doesn’t get filtered or cooled as often, making these systems much more sensitive to contamination.

Can I Use a Different Brand of Hydraulic Pump?

You can, but you have to be incredibly careful. Swapping in a pump from another manufacturer is not a simple plug and play. The replacement has to be an exact match in every critical area: displacement, pressure ratings, flow rate, and even the physical mounting bolts and ports. If anything is even slightly off, you risk poor performance, lost efficiency, or catastrophic damage to other parts of your hydraulic system.

When you are dealing with specialized equipment like amphibious excavators, cutting corners is not an option. It is vital to talk to an expert supplier. The new pump not only needs to match the specs on paper but also has to be tough enough for the relentless stress of working in water. A cheap replacement here will almost certainly lead to expensive downtime later.

At Wilco Manufacturing, we have over a century of combined experience building and servicing amphibious equipment for the world's most demanding jobs. Whether you need a new machine, a rental, or just some solid advice on a replacement part, our team is here to help you get the job done right. Contact us today to learn how our reliable equipment can solve your project challenges.