When you think of a major industrial project, whether it’s a skyscraper rising from the ground or a massive environmental cleanup, the excavator is almost always the star of the show. These machines are the true workhorses of the modern world, built for powerful digging, delicate material handling, and serious earthmoving. This guide explores the diverse applications of excavators, highlighting how specialized equipment like amphibious excavators solves industry-specific problems where standard machinery falls short.

The True Power of Modern Excavators

At its heart, an excavator solves a fundamental problem on any job site: how to move huge amounts of earth and heavy materials quickly and accurately. Its design, a rotating platform paired with a powerful boom and arm, lets it do the work of several machines, not to mention an entire crew of manual laborers.

This unmatched capability makes excavators absolutely essential in construction, mining, forestry, and infrastructure development. The global construction boom is a huge factor here. The excavator market was valued at USD 55.72 billion in 2025 and is expected to climb to USD 69.29 billion by 2029.

Core Functions and Capabilities

The real magic of an excavator is its adaptability. In just a few minutes, you can swap the attachment at the end of its arm and completely change its job. This is why project managers depend on them for the most critical tasks on site.

A single excavator can handle:

- Digging and Trenching: This is their bread and butter, perfect for creating building foundations or laying down pipelines and utility lines.

- Material Handling: They effortlessly load trucks with everything from soil and gravel to demolition debris.

- Grading and Landscaping: An experienced operator can shape the terrain for roads, new developments, or general site prep with incredible precision.

- Demolition: Outfit one with a hydraulic hammer or shear, and it becomes a demolition powerhouse, capable of breaking down old structures with ease.

But here’s the catch: standard excavators are land-based machines. They are unstoppable on solid ground but come to a grinding halt in mud, swamps, or water. This is where the industry has evolved, leading to specialized solutions like amphibious excavators that are built to work where others can't even move.

Keeping these complex machines running is a job in itself. As technology advances, so does maintenance, with new approaches like augmented reality for maintenance becoming more common to ensure uptime.

Excavator Applications in Construction and Infrastructure

Step onto any construction site, and the excavator is likely the first piece of heavy equipment you’ll see. These machines are the true workhorses of the industry, responsible for shaping the raw land into a workable project site. They do far more than just dig. They're the key to precision grading, foundational work, and setting the pace for the entire build.

From carving out the basement of a skyscraper to trenching for vital utility lines, excavators are simply non-negotiable. For a project manager, mastering the use of these versatile machines is fundamental to keeping a job on schedule and on budget.

Foundational and Earthmoving Tasks

The most obvious job for an excavator is bulk earthmoving. This is the brute-force phase of a project, where tons of soil, rock, and debris need to be cleared out quickly and efficiently. For these massive jobs, large excavators are brought in, leveraging their incredible hydraulic power to get the job done.

In this initial stage, their main jobs include:

- Digging Foundations: They excavate the deep, precise pits needed for building footings and basements, which form the literal bedrock of the structure.

- Trenching: They cut long, clean channels for laying essential utilities like water mains, sewer pipes, and electrical conduits.

- Grading and Site Preparation: This involves carefully shaping the terrain to create level building pads, sloped roads, and effective drainage systems.

A huge part of a project manager's job is picking the right-sized machine. It's a constant balancing act between raw power and site accessibility.

It really comes down to a trade-off. A massive excavator can move dirt in a fraction of the time, but a mini excavator might be the only option for a tight urban job site where you can't afford to block traffic or damage existing structures.

Choosing the Right Machine for the Job

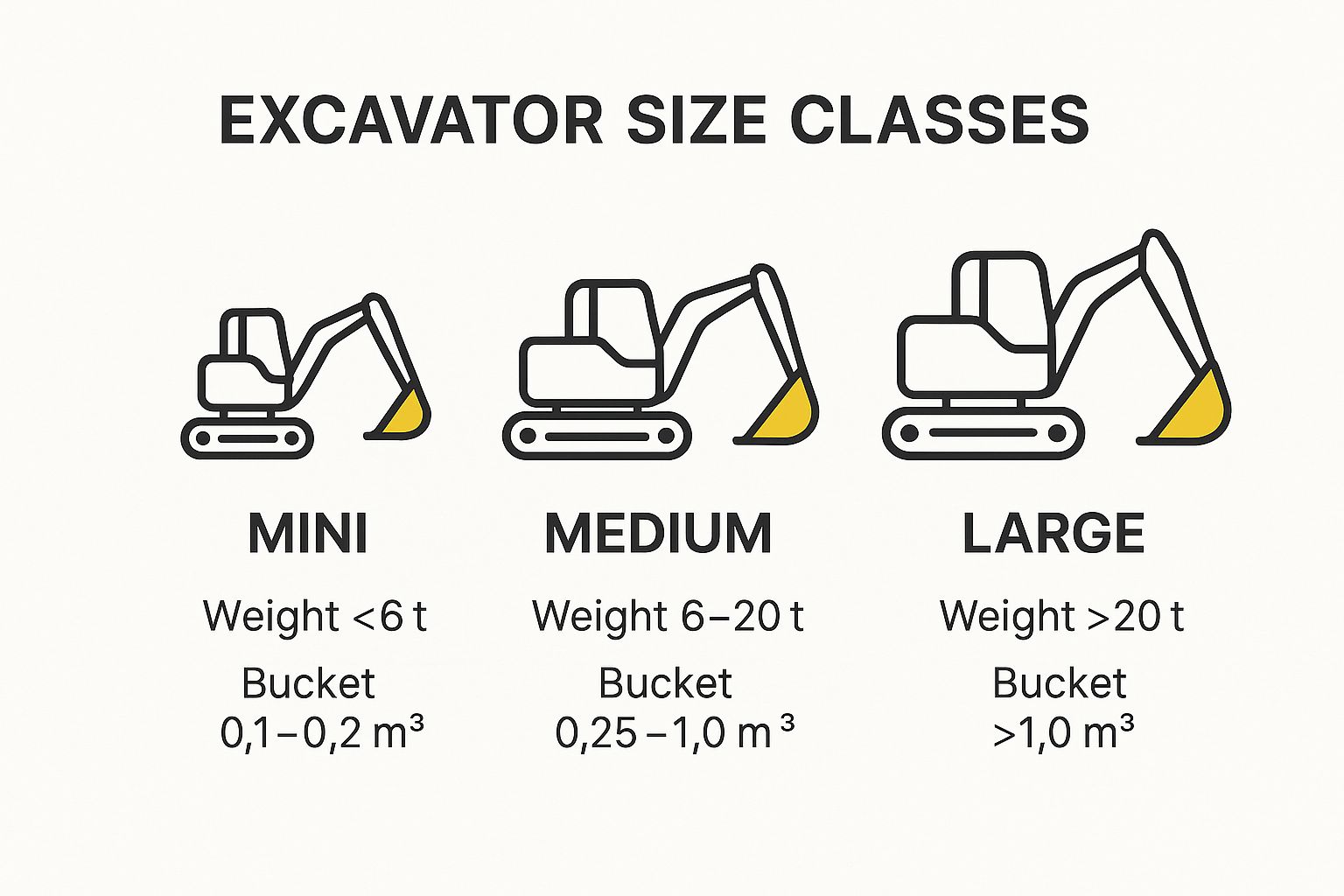

The image below gives a great visual breakdown of the three main excavator size classes, showing how their weight and bucket capacity directly correlate with the scale of the project.

As you can see, the bigger the machine, the better it is for major earthmoving, making large excavators the go-to for sprawling infrastructure projects. It’s no surprise that construction applications dominate the global market, accounting for roughly 70% or more of all excavator use.

But even the most powerful land-based excavator has its limits. What happens when the ground is too soft, marshy, or even underwater? That's when you need a specialist. The unique design of an amphibious excavator allows it to work in environments that would completely sideline a standard machine.

To better understand where each machine shines, let's compare their core differences.

Comparing Standard and Amphibious Excavators

| Feature | Standard Excavator | Amphibious Excavator |

|---|---|---|

| Undercarriage | Standard steel tracks or wheels. | Large, hollow pontoon tracks for buoyancy. |

| Ideal Terrain | Firm, stable ground like soil, clay, and gravel. | Swamps, marshes, riverbeds, and shallow waters. |

| Primary Use | General construction, road building, mining. | Dredging, shoreline restoration, wetland construction. |

| Mobility | Limited to land-based movement. | Can travel on land and float/propel in water. |

| Ground Pressure | High pressure, can damage soft surfaces. | Very low ground pressure, minimizes environmental impact. |

This comparison makes it clear that while standard excavators are the backbone of most construction projects, amphibious models open up a whole new world of possibilities for working in challenging, water-logged environments.

Operating Where Standard Machines Cannot Go

Standard excavators are the undisputed workhorses on solid ground. But what happens when the job site is a swamp, a marsh, or the edge of a river? That’s where conventional heavy machinery grinds to a halt. The soft, saturated ground that would swallow a typical trackhoe is the natural habitat for an amphibious excavator.

These are not just standard excavators with oversized tracks bolted on. They are highly specialized machines engineered from the ground up for work in and around water. Here at Wilco Manufacturing, we build them with a unique undercarriage made of large, hollow pontoons. This design gives them the buoyancy to float on water and navigate terrain so soft it's impassable for anything else.

This one feature completely changes the game on challenging projects. Instead of building expensive temporary roads or coordinating multiple barges, both of which cause significant environmental disruption, an amphibious excavator simply drives right to where the work needs to be done.

Solving Impossible Terrain Challenges

The true magic of an amphibious excavator is its ability to turn a logistical nightmare into a manageable project. By spreading its weight across a massive surface area, it exerts incredibly low ground pressure. This prevents it from sinking and, just as importantly, minimizes damage to sensitive ecosystems.

Consider a few real-world situations where this kind of machine is not just a better option, it's the only option:

- Dredging Vital Waterways: A critical shipping channel or drainage canal is clogged with silt. An amphibious excavator can wade directly into the water, scoop out the material, and place it neatly on the bank, all without a single barge in sight.

- Restoring Fragile Coastlines: After a major storm, coastal wetlands need rebuilding to protect communities inland. These machines can move through delicate marshland with a light touch, precisely placing restorative materials where they're needed most.

- Pipeline Installation in Swamps: Imagine trying to lay a pipeline through a remote swamp. The logistical hurdles are staggering. Amphibious equipment makes it possible by clearing the path and digging the trench directly in the waterlogged soil, keeping the project on schedule.

An amphibious excavator transforms a project liability into a workable site. It eliminates the need for extensive site prep, letting work start faster with a far smaller environmental footprint, a huge win for both contractors and environmental agencies.

Engineered for Aquatic Environments

While the pontoon undercarriage is the heart of an amphibious excavator, the engineering doesn't stop there. The entire system has to be tough enough to withstand the corrosive power of saltwater and the constant abrasion from sand and sediment.

At Wilco Manufacturing, our amphibious undercarriages are constructed from high-strength, corrosion-resistant steel built for this punishment. In shallow water, operators can use the boom and bucket to push or pull the machine along the bottom. For deeper jobs, we can add optional hydraulic thrusters, effectively turning the excavator into a self-propelled floating work platform with pinpoint maneuverability.

For projects in wetlands, marshes, and waterways, this specialized design isn't just an alternative. It is often the definitive solution, offering a blend of safety, efficiency, and environmental care that no other machine can match.

Environmental Cleanup and Land Restoration

Excavators are more than just dirt movers. They're critical tools for healing landscapes scarred by industry or natural disasters. On these sensitive, often unstable job sites, brute force takes a backseat to precision and a light touch. This is exactly where specialized excavators, especially amphibious models, really prove their worth.

Their design allows them to work in fragile ecosystems with the least possible disturbance. For example, consider removing contaminated sediment from a riverbed. A standard excavator would need disruptive access roads or expensive barges. An amphibious machine, on the other hand, can walk right into the water, performing delicate removal work without further damaging the very habitat we're trying to save.

Precision Work in Sensitive Environments

Many environmental projects send us into places that are ecologically delicate and a nightmare to access. Amphibious excavators are purpose-built for these challenges, giving us a stable platform in wetlands, marshes, and shallow waters where other machines would be useless.

Common restoration tasks where they excel include:

- Contaminated Sediment Removal: Precisely scooping polluted soil from riverbeds and lake bottoms, a key step in improving water quality and bringing back aquatic life.

- Invasive Species Management: Clearing out dense, invasive plants from protected wetlands to give native vegetation a chance to thrive again.

- Habitat Restoration: Rebuilding eroded coastlines, recreating wetland habitats after industrial spills, and sculpting shorelines to better support local wildlife.

Excavators have come a long, long way from the clunky steam shovels of the 19th century. Today’s machines are packed with advanced tech to meet tight environmental rules and get the job done efficiently, a must-have for any restoration project. You can find out more about how these machines evolved from early models into the eco-friendly equipment we rely on today.

In environmental cleanup, the goal is always to leave the site better than you found it. Amphibious equipment is key to this, as its low ground pressure avoids the deep ruts and soil compaction that can stall an ecosystem's recovery for years.

A Case for Specialized Equipment

Imagine you’re tasked with restoring a protected marshland choked out by an invasive reed. The ground is far too soft for any standard machine, and the water is too shallow for a dredging barge. This is the classic scenario where an amphibious excavator is not just a good choice, it's the only choice.

It can move across the saturated ground without sinking, using a specialized rake or bucket to pull out the invasive plants while leaving the native root systems undisturbed. That kind of precision is what makes or breaks the long-term health of the ecosystem. By picking the right tool for the job, project managers can execute complex restoration plans that are both effective and sustainable. This approach is a core part of modern equipment for dredging and environmental work.

At the end of the day, these machines are more than just tools. They are foundational solutions for protecting and restoring our natural world.

Essential Roles in Pipeline and Utility Projects

In the energy and utility sectors, excavators are the absolute workhorses of any major infrastructure project. Their most visible job is trenching, the methodical process of digging long, precise channels for pipelines carrying oil, gas, and water across the country. This isn't just about raw power to tear through tough soil. It requires finesse to maintain exact depths and grades over miles of terrain.

But their work doesn't end once the pipe is in the ground. Excavators are just as vital for the entire lifecycle of a pipeline, from maintenance to emergency repairs. When a section needs inspection or fixing, these machines are called in to delicately peel back the earth and expose the line. This is painstaking work, especially around live, high-pressure utilities where one wrong move could have catastrophic results.

Overcoming Challenging Terrain

Standard excavators are champions on dry, solid ground. But what happens when the planned route for a pipeline cuts straight through a swamp, a marsh, or a river? Suddenly, that conventional machine becomes more of a liability than an asset. It can easily get bogged down, sink, and create a massive safety and logistical nightmare.

This is exactly the scenario where amphibious excavators go from being a specialty item to an absolute necessity. Equipped with large, buoyant pontoon undercarriages, they can glide across saturated ground and even float on water, giving crews a stable platform where other equipment simply can't operate.

Think about it. For a wetland crossing, the old way involved building expensive temporary roads or bringing in massive crane and barge systems. Amphibious excavators make all of that obsolete. They can drive right into the work area with minimal environmental impact, dig the trench, help lay the pipe, and backfill, all while navigating the soupy terrain. If you're facing these kinds of conditions, looking into amphibious excavators for rent can give you the right tool for the job without the hefty price tag of ownership.

Projects that cross wetlands or coastal plains present unique safety and logistical challenges. The stability and mobility of amphibious equipment, like Wilco’s hydraulic undercarriages, are essential for maintaining project timelines and ensuring crew safety in these unforgiving environments.

The Amphibious Advantage in Practice

Let’s put this into a real-world context. Imagine a pipeline project needs to cross a two-mile stretch of protected marshland. The ground is far too soft for a standard trackhoe, and strict environmental rules forbid building a temporary causeway.

This is where an amphibious excavator becomes the hero of the story. It can navigate the entire distance, clearing the path, digging the trench, and assisting crews with positioning each section of pipe.

What was once a project-stopping obstacle is now just another part of the job. By delivering the stability and mobility needed to work on waterlogged ground, amphibious excavators provide a practical, effective solution to some of the toughest challenges in the industry. They ensure that critical infrastructure gets built and maintained safely, no matter what the landscape throws at you.

How to Select the Right Excavator

Picking the right excavator for a job is one of those decisions that can make or break your entire project. Get it wrong, and you're looking at frustrating delays and a budget that's spiraling out of control. But when you get it right, the job flows smoothly, safely, and wraps up right on schedule. It all comes down to truly understanding what your project needs.

The first step is to get back to basics and look at the core demands of the job. What are the digging depths you need to hit? How much lift capacity is non-negotiable? You also have to consider the site itself. Are there tight access points or strict weight limits to worry about? Answering these questions first will quickly help you zero in on the right size and class of machine.

Matching the Machine to the Environment

Once you have the specs nailed down, it’s time to look at the ground you'll be working on. For most jobs on solid ground, rocky soil, or in a developed urban area, a standard tracked or wheeled excavator will get the job done just fine.

But the game completely changes the moment the ground gets soft and saturated. In those conditions, a conventional machine goes from an asset to a massive liability, bogged down and useless. For any project that involves working in soft soil, marshes, swamps, or shallow waterways, the choice becomes crystal clear.

This is exactly where an amphibious excavator shines. These machines were designed from the ground up for these tough environments. Their buoyant, pontoon-style undercarriage and incredibly low ground pressure keep them from sinking, giving you a stable, mobile platform where a normal excavator would be stuck.

This isn't just a minor feature. It is a critical capability for work like dredging, environmental restoration, and pipeline construction in delicate wetlands. To really get a feel for how this specialized equipment stacks up, it helps to compare it to other options. You can explore the key differences between amphibious crawlers and traditional marsh buggies to see why purpose-built gear is so effective.

At the end of the day, the "best" excavator is simply the one that perfectly fits your project's goals and, most importantly, its environment. If you're on firm land, a standard machine is your workhorse. For everything else, specialized amphibious equipment is not just a good idea, it's the only way to guarantee success.

If you're staring down a challenging project and need a hand figuring out the perfect machine, our team at Wilco Manufacturing is ready to help. Contact us, and we can talk through your specific needs to find the right equipment solution.

Got Questions? We've Got Answers

Let's tackle some of the most common questions that come up when people are trying to wrap their heads around what these machines can really do. Getting these distinctions right can make all the difference on a job site.

How Does an Amphibious Excavator Actually Move in the Water?

It's a great question. At first glance, it seems impossible, but it's all in the undercarriage. Amphibious excavators are built on a sealed, pontoon-style base that gives them the buoyancy to float.

Once they're in the water, they can actually propel themselves through shallower areas by using the boom and stick to push or pull along the bottom. For deeper water where the arm can't reach, they can be fitted with hydraulic thrusters. This smart design creates a remarkably stable working platform right on the water's surface, which is essential for jobs like dredging or environmental cleanup.

What’s the Real Difference Between an Excavator and a Backhoe?

This is a classic one. The biggest giveaway is how they rotate and what they're built on. An excavator's entire house, the cab and the boom, can spin a full 360 degrees on top of its tracks. This gives it a massive working radius without having to move the whole machine.

A backhoe, on the other hand, is basically a tractor with a loader on the front and a digging arm on the back. That rear arm can only pivot about 200 degrees. Because of this fundamental difference, excavators are generally bigger and are the go-to choice for heavy-duty, large-scale projects where you need that full range of motion.

When Should I Use a Mini Excavator Instead of a Standard One?

A mini excavator shines when you're working in tight quarters. If a standard machine can't physically fit, the mini is your hero. Think about projects like residential landscaping, indoor demolition, or utility work in narrow city alleyways.

Their smaller footprint and lighter weight also mean they do far less damage to the ground, which can be a huge plus. But when you need serious digging depth, reach, and lifting power on a big, open site, that's when you have to bring in the standard-sized excavator.

When your project takes you to the water's edge and beyond, standard equipment just won't cut it. Wilco Manufacturing builds the specialized solutions you need to get the job done. Talk to our experts today and let's figure out the right amphibious equipment to help you conquer any terrain.