When it comes to modern construction, dredging, or environmental remediation, the excavator is an undisputed workhorse. However, not all excavators are created equal. Selecting the right machine is a critical decision that directly impacts your project's efficiency, budget, and safety. The world of excavators is surprisingly diverse, ranging from standard crawler models seen on most job sites to highly specialized amphibious units engineered to conquer the toughest wetland environments.

This guide provides a practical breakdown to help decision-makers understand the real-world differences between excavator types and how to match the right equipment to specific project challenges.

An Introduction to the World of Excavators

Constant innovation from leading manufacturers like Komatsu has pushed these machines to tackle jobs once considered impossible. We will cover the full spectrum of equipment, from common crawlers and nimble mini excavators to impressive long-reach models. Special attention will be given to amphibious excavators, a core focus for us at Wilco Manufacturing, as they are engineered to solve problems where traditional equipment would literally sink.

Our goal is to provide project managers and decision-makers with the insights needed to pair the right machine with any operational challenge. Understanding the specific strengths of each excavator type allows you to make smarter choices that enhance safety, drive productivity, and lead to successful project outcomes.

The Anatomy of an Excavator

Before diving into different models, let's quickly review the machine's core components. An excavator is a powerful, intricate system where every part serves a specific function. It can be broken down into three main sections:

- The Undercarriage: This is the machine's foundation, providing stability and mobility. It consists of tracks (or wheels), rollers, and sprockets that grip the ground and propel the excavator.

- The House: Situated atop the undercarriage, the house is the command center. It contains the operator's cab, engine, hydraulic pumps, and a heavy counterweight for balance. The house can rotate a full 360 degrees, allowing the operator to dig and dump material without repositioning the entire machine.

- The Arm Assembly: This is the excavator's working end. It comprises the boom (the large section attached to the house), the stick (or dipper arm), and the bucket (or other attachment). This entire assembly provides the excavator's reach and digging power.

The secret to an excavator's massive strength lies in its hydraulic system. The engine powers pumps that force hydraulic fluid through a network of hoses and valves, creating incredible pressure. This pressure allows the operator to move the arm, stick, and bucket with both immense force and surprising precision.

By understanding these fundamentals, you are better equipped to select a machine that not only meets but exceeds your project's demands, ensuring a safe and efficient operation from start to finish.

Understanding Your Foundational Choices

Nearly every excavator falls into one of two primary categories: crawlers or wheeled models. Each is built for a different environment, and knowing their core strengths is the first step toward choosing the right tool. The decision almost always comes down to a trade-off between stability and mobility.

The most common machine is the crawler excavator, often called a tracked excavator. Its most recognizable feature is the heavy-duty undercarriage running on steel tracks, similar to a tank. This design provides incredible stability and traction, making it the champion on challenging job sites.

Crawler excavators excel on soft ground, mud, gravel, or hilly terrain where a wheeled machine would struggle for grip or become bogged down. By distributing their immense weight over a large surface area, they create a solid footing essential for heavy lifting and aggressive digging.

Crawler Excavators: The Ground Force of Construction

This raw stability makes crawler excavators indispensable for large, demanding projects. Their low center of gravity and phenomenal grip allow them to handle tough jobs with both power and precision.

You will see crawlers as the go-to choice for applications like:

- Heavy Earthmoving: Digging massive foundations or clearing land for major infrastructure.

- Mining Operations: Loading and hauling tons of rock and ore across rugged landscapes.

- Large-Scale Demolition: Tearing down structures and handling heavy debris on unstable ground.

- Pipeline Trenching: Carving long, deep trenches through various soil conditions.

The key advantage of a crawler is its ability to create an immovable platform for digging. This allows the operator to apply maximum breakout force without the machine tipping or shifting, which is critical for completing work safely and efficiently.

This fundamentally sound design has even been adapted for the most extreme environments. By replacing standard tracks with specialized pontoons, a crawler can be modified to work in swamps or float on water. This concept is engineered into specialized amphibious hydraulic undercarriages built for the toughest wetland projects.

Wheeled Excavators: The Urban Mobility Specialist

On the other side, the wheeled excavator brings a different set of skills focused on speed and versatility, particularly in urban or developed areas. As its name implies, it sits on heavy-duty rubber tires instead of tracks. This allows it to travel on paved roads without damaging the asphalt.

This mobility is its greatest advantage. A wheeled excavator can drive itself between tasks on a long roadwork project or move from one site to another across town, all without needing a lowboy trailer for transport. This cuts down on logistics, reduces downtime, and ultimately saves time and money.

While it lacks the brute stability of a crawler, a modern wheeled excavator uses outriggers or a dozer blade to lock itself in place for digging. Its value is undeniable in environments dominated by concrete and asphalt where maneuverability is paramount.

The power behind both of these workhorses comes from hydraulic systems. In fact, hydraulic excavators make up over 70% of the market revenue. Crawler models lead the charge, being the first choice for major infrastructure and mining projects where their unbeatable stability is non-negotiable.

A Look at Excavators for Specialized Jobs

While crawler and wheeled excavators are the workhorses of most construction sites, some projects present unique challenges. In these cases, standard equipment may be too large, clumsy, or completely unsuitable for the environment.

This is where specialized excavators come in. Choosing the right machine for a niche job can turn a logistical nightmare into a smooth, efficient operation. Let’s break down two of the most common specialists: mini excavators and long-reach excavators.

Mini Excavators: Power in a Small Package

Mini excavators, often called compact excavators, are the undisputed champions of tight spaces.

For example, a project might require digging a narrow trench for a utility line in a manicured backyard without destroying the lawn. Another common challenge is performing demolition inside a building where a full-sized machine cannot fit through the doorway. These are the jobs where a mini excavator truly shines.

Their effectiveness lies in a simple combination of a small footprint, light weight, and nimble maneuverability. This allows them to get in, complete the job with minimal ground disturbance, and get out.

You will often find them working on:

- Urban utility projects, digging on sidewalks or in narrow alleyways.

- Landscaping jobs requiring precise digging around existing structures and plants.

- Indoor demolition, navigating through doorways to work inside buildings.

- Swimming pool installations in backyards with limited access.

The demand for these compact powerhouses is growing. As detailed in market analysis from Grand View Research, the entire excavator market is expanding, with the mini excavator segment being a major driver as more work occurs in congested urban and environmentally sensitive areas.

Long-Reach Excavators: When You Need to Go the Distance

Now, let's pivot from confined spaces to long distances. A long-reach excavator does exactly what its name suggests, it reaches far beyond the capabilities of a standard machine.

Imagine an operator sitting safely on a riverbank while dredging a channel far out into the water. Or consider dismantling a tall structure piece by piece from a safe distance. This is the domain of a long-reach excavator.

These machines are built with an extended boom and arm, some of which can stretch over 100 feet. This incredible reach allows a single machine to perform jobs that might otherwise require barges, cranes, or costly scaffolding, saving a significant amount of time and money.

The real advantage of a long-reach excavator is its ability to cover a massive working area from a single, stable position. This is a game-changer for deep excavations, dredging, and finishing steep slopes.

This extended capability makes them essential for a range of specialized work, particularly in demolition and environmental remediation where distance equals safety. Of course, even a long-reach machine has its limits. For jobs that require working in the water or a swamp, not just over it, you will need a true specialist. That is when looking into amphibious excavators for rent becomes the only way to get the job done safely and effectively.

Conquering Wetlands and Waterways

For most projects, you can count on solid ground under your tracks. But what happens when the worksite is a swamp, a marsh, or a shallow river? This is a non-starter for conventional equipment. The ground is too soft, the machine will get bogged down, and the entire project will grind to a halt.

This is precisely the problem the amphibious excavator was built to solve. It is not just another type of excavator; it is a complete re-engineering of where a machine can go and what it can do. It is the ultimate all-terrain solution, designed to work in places that would swallow other machines whole.

While a standard crawler needs firm footing, an amphibious excavator is designed for the opposite. It delivers incredible performance in the kind of soupy, unstable environments that would instantly immobilize anything else.

The Engineering Behind Amphibious Dominance

The magic of an amphibious excavator lies in its undercarriage. Instead of the typical steel tracks of a crawler, it rides on two massive, buoyant pontoons. This design is the key to its unique capabilities.

These pontoons accomplish two critical things:

- Flotation: The pontoons are sealed and airtight, allowing the entire machine, weighing upwards of 30 tons, to float on water. This turns rivers, flooded fields, and canals into workable job sites.

- Weight Distribution: On soft terrain like mud, silt, or marshland, the pontoons spread the excavator’s weight over a huge surface area. This results in extremely low ground pressure, preventing it from sinking into ground a person could not even walk across.

This unique undercarriage turns hostile environments into productive work zones. The machine can move from floating in a channel to crawling up a muddy bank without missing a beat, giving operators a level of access that was once unthinkable.

An amphibious excavator is not just a machine that can get wet. It is a purpose-built tool designed to make swamps, wetlands, and waterways accessible, fundamentally changing how we approach projects in these sensitive areas.

Real-World Applications in Challenging Terrains

The ability to work directly in water and on saturated soil opens the door to a range of jobs that would otherwise be impossible, inefficient, or environmentally damaging. Amphibious excavators have become indispensable tools for both critical infrastructure and environmental projects.

For example, consider a pipeline that needs to cross a protected marsh. The traditional method might involve building expensive temporary roads, which disrupts the ecosystem. An amphibious excavator, however, can simply traverse the marsh with minimal impact, dig the trench, and help restore the area as it moves. For a closer look at how these machines compare to other specialized gear, exploring the differences between advanced amphibious vehicles and traditional marsh buggies offers valuable insight.

These machines are the first choice for:

- Environmental Cleanup: Removing contaminated sediment from riverbeds or cleaning up after spills in wetlands.

- Dredging and Waterway Maintenance: Clearing silt and debris from canals and ports to keep them navigable and improve water flow.

- Coastal and Wetland Restoration: Rebuilding eroded shorelines, creating wildlife habitats, and managing vegetation in protected areas.

- Pipeline and Utility Installation: Laying pipes and cables through swamps, across rivers, and in floodplains.

By enabling work in these tough locations, amphibious excavators allow project managers to complete critical jobs safely and with a much lighter environmental footprint. Wilco Manufacturing has been a leader in this field, building the tough, reliable amphibious systems that make seemingly impossible projects a reality.

How to Select the Right Excavator for Your Project

Choosing the right excavator is not just about picking the biggest machine; it is a strategic decision that can make or break your project's timeline and budget. Getting this wrong leads to wasted time and money, while the right choice ensures maximum efficiency from day one.

First, assess the site conditions. What is the ground like? Are you dealing with solid rock, soft clay, or a swampy marsh? For tricky, uneven terrain, a standard crawler excavator provides the best stability. However, if you are working in wetlands, an amphibious model is the only tool for the job.

Next, consider the logistics. How will you transport the machine to the site, and how much room will it have to maneuver? A tight urban demolition or an indoor project often requires a mini excavator that can navigate confined spaces. Large, open sites, on the other hand, allow for larger, more powerful equipment.

Evaluating Project Scope and Material

The job itself will dictate much about the machine you need. Ask yourself two questions: How deep do I need to dig, and how far do I need to reach? If you are trenching deep utility lines or dredging a canal, a long-reach excavator is specifically designed for that kind of work, allowing you to complete it without constant repositioning.

The material you are moving is also critical. Shoveling light sand is entirely different from breaking up and hauling dense rock. Determine the volume and weight of the material to be handled. This will help you select an excavator with the right power and bucket capacity, ensuring you do not end up with an underpowered machine that slows down the entire operation.

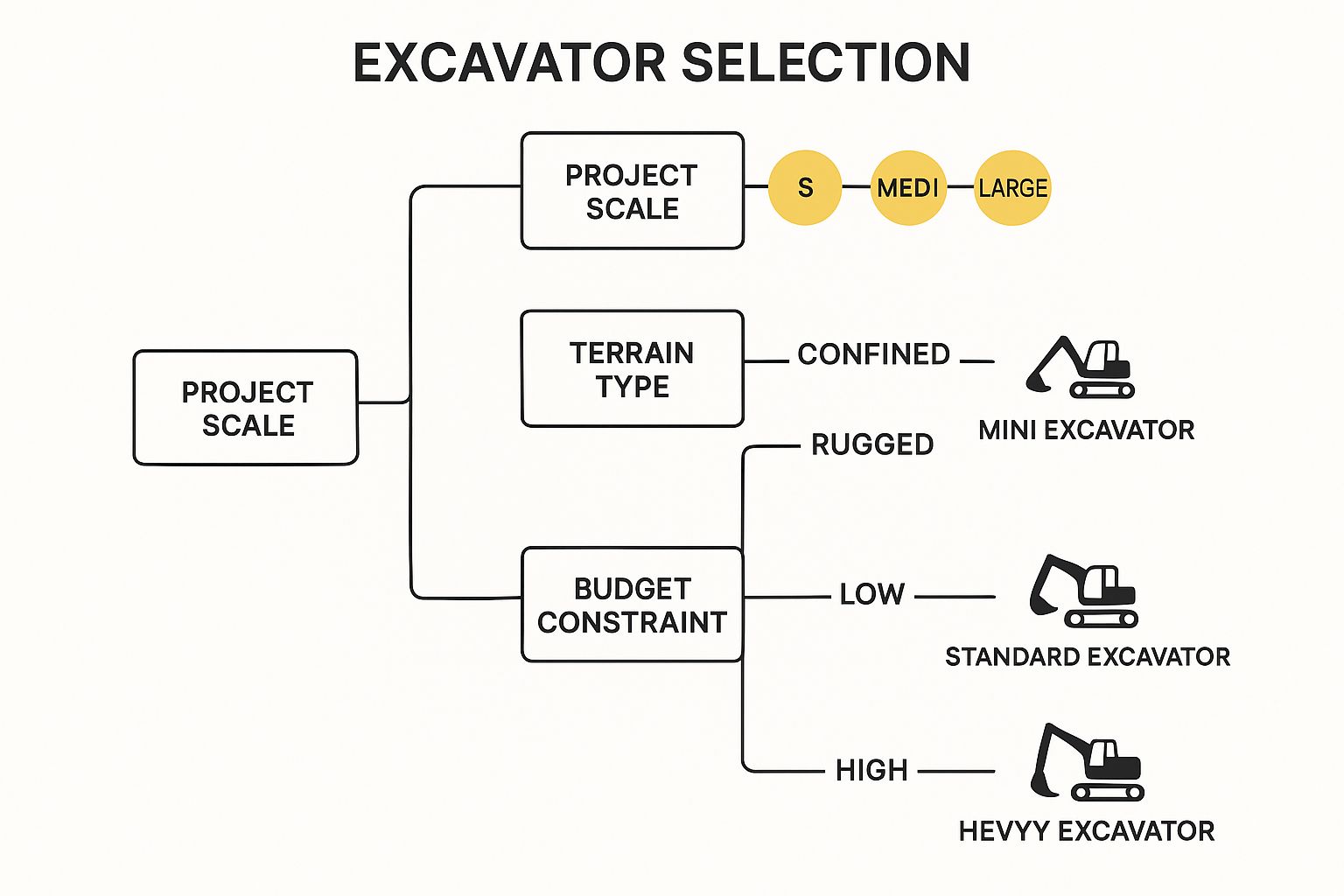

This visual guide breaks down how project scale and terrain should point you toward the right machine.

As you can see, a small job in a tight spot is a clear case for a mini excavator. But as the project gets bigger and the ground gets rougher, you will need a more powerful solution like a crawler.

To help you put all the pieces together, here is a quick comparison of the main excavator types and where they excel.

Excavator Type Comparison for Project Planning

This table provides a high-level overview to guide your initial selection process, matching machine strengths to project demands.

| Excavator Type | Primary Application | Key Advantage | Best Suited Terrain |

|---|---|---|---|

| Standard Crawler | General construction, large-scale excavation | Excellent stability and power | Uneven, soft, or rugged ground |

| Mini Excavator | Urban projects, landscaping, indoor work | High maneuverability in tight spaces | Confined areas, finished surfaces |

| Long-Reach Excavator | Dredging, demolition, deep trenching | Extended boom for superior reach | Stable ground with distance obstacles |

| Amphibious Excavator | Wetland restoration, swamp work, dredging | Floats and operates in water | Marshes, swamps, shallow waterways |

Remember, this is a starting point. The real key is to weigh all factors together to find the perfect fit.

Key Factors for Your Needs Analysis

To finalize your decision, run through this quick checklist. It ensures you are not overlooking a critical detail that could cause issues later.

- Project Size and Duration: For large, long-term jobs, purchasing equipment may be practical. For shorter or highly specialized tasks, renting is almost always the smarter financial decision.

- Digging Depth and Reach: Know the absolute maximum depth and horizontal reach your project requires to avoid selecting a machine that literally comes up short.

- Lifting Capacity: If you will be lifting and placing heavy items like concrete barriers or pipe sections, check the excavator’s lift chart. You need to ensure it can handle the weight safely without tipping.

A common mistake is focusing on one specification, like digging depth, while forgetting about site access or ground conditions. A successful project depends on a holistic analysis that balances every requirement.

Once you have selected your machine, the next step is ensuring safe operation. This is where well-defined Safe Work Procedures (SWPs) become essential.

Looking at the bigger picture, construction continues to be the primary driver for these machines, accounting for about 60% of all excavator use. The industry is also seeing a major push toward hybrid and electric models to reduce emissions, and the rental market is booming.

Ready to Partner with an Expert?

Knowing the difference between various excavator types is one thing, but when your project is located in a swamp, wetland, or waterway, that knowledge is just the beginning. True success in these challenging environments comes from partnering with a specialist who understands them inside and out. The right machine is not just a piece of equipment; it is the core of a strategy that determines project success.

Standard equipment simply cannot perform on sensitive or waterlogged terrain. This is precisely where amphibious excavators change the game.

Turning Tough Jobs into Triumphs

Amphibious excavators are built to work where other machines would get hopelessly stuck or sink. They can float across water and navigate soft, boggy ground with minimal impact, opening up job sites once considered inaccessible.

This is not just about getting the job done, it is about doing it smarter and safer.

These machines are indispensable for critical work like:

- Pipeline Installation: Laying essential infrastructure through marshland without building expensive, destructive access roads.

- Environmental Restoration: Allowing crews to access the heart of an ecosystem to restore coastlines, rebuild habitats, or clear invasive plants.

- Waterway Maintenance: Working directly on the water to clear shipping channels or manage water flow in basins for maximum efficiency.

Choosing specialized equipment is not a workaround. It is about adopting a purpose-built strategy to work safer, protect the environment, and deliver better results on time and on budget.

If you are a decision-maker in the dredging, pipeline, or environmental remediation industries, this capability provides a massive advantage. We dive deeper into this topic in our guide to specialized equipment for dredging.

Moving from understanding excavators to completing a successful project in a tough environment requires more than just a machine; it requires the right partner. At Wilco Manufacturing, we do not just sell equipment. We engineer complete solutions for your most demanding challenges. Our team has the field-tested experience to help you choose, configure, and deploy the right amphibious equipment for your exact needs.

Ready to tackle your next project with a genuine advantage? Let's talk. Contact the Wilco team today to see how our custom-engineered solutions can help you succeed.

Common Questions About Specialized Excavators

When dealing with tricky or unusual job sites, determining which excavator to use can be a challenge. The right choice can save your budget and timeline, while the wrong one can bring a project to a grinding halt. Let's tackle some of the most frequent questions project managers ask when weighing their options.

This section serves as a practical guide to matching the machine to the mission, ensuring you have the right tool for the job.

What's the Real Difference Between a Standard and an Amphibious Excavator?

The crucial difference is the undercarriage, which completely dictates where the machine can work. A standard excavator, whether on tracks or wheels, is a land-based machine built for solid footing like dirt, gravel, or pavement.

An amphibious excavator, however, is a different machine entirely. It rides on a pontoon-style undercarriage. This design allows the entire machine to float and navigate through water or across ultra-soft ground like swamps, marshes, and dredging spoils. The pontoons spread the excavator's weight over such a large area that it avoids sinking in mud that would swallow a standard machine.

Can't I Just Use a Long-Reach Excavator for Dredging?

You can, but only from the sidelines. A long-reach excavator is perfect for dredging when it can sit on a stable, dry spot like a riverbank, barge, or causeway. Its extended arm can reach far out over the water to pull material back. The key is that the machine itself remains on solid ground.

An amphibious excavator, on the other hand, operates directly in the water or wetland. This makes it infinitely more effective for jobs that require the machine to move through a waterway, such as clearing an entire channel, restoring a large marsh, or handling widespread sediment removal.

The choice is simple. If you can complete all work from the shore, a long-reach might be suitable. If the machine needs to be in the water to do the job, you absolutely need an amphibious excavator.

When Should I Pick a Mini Excavator Over a Standard Machine?

A mini excavator is your go-to solution whenever space is tight. It excels in residential backyards, crowded urban utility work, and even indoor demolition projects where a standard excavator could not fit.

Because they are lighter and more compact, they also cause far less ground disturbance and are easier to transport. You will want to step up to a standard excavator for larger jobs like commercial site development, major road construction, and heavy earthmoving. Those projects demand the deep digging, heavy lifting, and long reach that only a full-size machine can provide, and they usually occur on sites with ample room to maneuver. The decision boils down to the scale of the work versus the constraints of the job site.

When your project calls for more than what standard equipment can handle, you need a partner who specializes in advanced machinery. Wilco Manufacturing builds tough, reliable amphibious equipment designed to master the world's most difficult terrain. Contact us to discuss your project and see how we can help you tackle the impossible.