An excavator rotating grapple is a specialized hydraulic attachment that transforms a standard excavator from a simple digging machine into a precision material handler. Unlike a fixed bucket, this tool features powerful gripping jaws and can rotate a full 360 degrees. This allows an operator to pick up, sort, and place materials like logs, pipes, or demolition debris without constantly repositioning the entire machine. For industries like land reclamation, dredging, and construction, this capability is not just an upgrade, it is a fundamental shift in efficiency.

What an Excavator Rotating Grapple Actually Does

The best way to think of it is like adding a wrist to the end of an excavator's arm. This simple concept is at the heart of its effectiveness. It gives the operator a level of dexterity and fine-tuned control that is impossible to achieve with a standard bucket or a non-rotating grapple.

This precision is crucial on complex job sites. Whether you are dredging in sensitive wetlands or carefully sorting mixed materials at a demolition site, the ability to rotate the load provides a massive advantage. For project managers, this attachment is more than a tool. It is a direct path to greater efficiency and a healthier bottom line.

Key Benefits for Project Efficiency

- Faster Cycle Times: Operators can grab, twist, and place materials in one smooth, continuous motion. This slashes the time spent repositioning the excavator, which means tasks like loading trucks or carefully placing riprap get done much faster.

- Reduced Fuel Consumption: Since the machine moves less, it burns less fuel. The rotating grapple allows the operator to work effectively from a single position, leading to significant cost savings over the life of a project.

- Enhanced Job Site Safety: Precise control over heavy, awkward objects is a huge win for safety. Operators can place materials exactly where they need to go, build more stable piles, and prevent dangerous, uncontrolled swings.

The industry is clearly taking notice. The global market for heavy-duty grapple attachments was valued at around USD 1.8 billion in 2023 and is expected to climb to USD 3.2 billion by 2032. This is not just a niche tool anymore. It is a clear trend toward equipment that can do more, more efficiently. You can dig into this market trend further over at Verified Market Reports.

Ultimately, outfitting an excavator with a rotating grapple is a smart investment, especially for amphibious models working in challenging environments. In fact, it's one of the most popular Wilco Marsh Runner attachments because it transforms a powerful machine into a versatile, high-precision workhorse. This guide will show you exactly how this attachment delivers a real return on investment in the most demanding industries.

A Look Under the Hood: The Engineering Behind the Grapple

To truly understand why an excavator rotating grapple is such a game-changer, you must appreciate the engineering that gives it both brute strength and surgical precision. It is a masterpiece of hydraulic design, where every component is built to withstand the toughest job site conditions. At its heart, the system boils down to three key elements working together seamlessly.

The real magic is in the hydraulic system. Think of it as the grapple's heart and muscles combined. It pushes high-pressure fluid from the excavator to perform two functions at once: delivering the crushing force needed to clamp the jaws shut and providing the smooth, 360-degree rotation that makes it so versatile. This dual-action capability is what sets a rotating grapple apart from more basic attachments.

Core Mechanical Components

It all starts with high-strength steel. These attachments are built to handle the immense stress of lifting, twisting, and sorting heavy, awkward materials day in and day out.

- The Hydraulic Rotator: This is the "wrist" of the operation. It is a tough, self-contained motor that lets the grapple spin endlessly in either direction. This gives the operator total control to orient the load exactly as needed.

- Powerful Cylinders: These are the muscles that open and close the grapple's jaws, often called tines. The hydraulic cylinders provide the raw clamping power required to get a firm grip on everything from giant logs to slick steel pipes.

- The Reinforced Steel Frame: The entire attachment is mounted on a heavy-duty frame that connects directly to the excavator's arm. This is the structural backbone, engineered to absorb shock and distribute stress, which is key for long-term durability.

A good way to think about it is to picture a human hand. The rotator gives you the flexible movement of a wrist, while the tines act like strong, precise fingers that can lock onto a load and not let go. This design provides a real-world edge on the job, like being able to place materials perfectly in a tight spot. In fact, a lot of modern engineering relies on creating 3D models to digitally prototype and refine these grapple designs before a single piece of steel is ever cut.

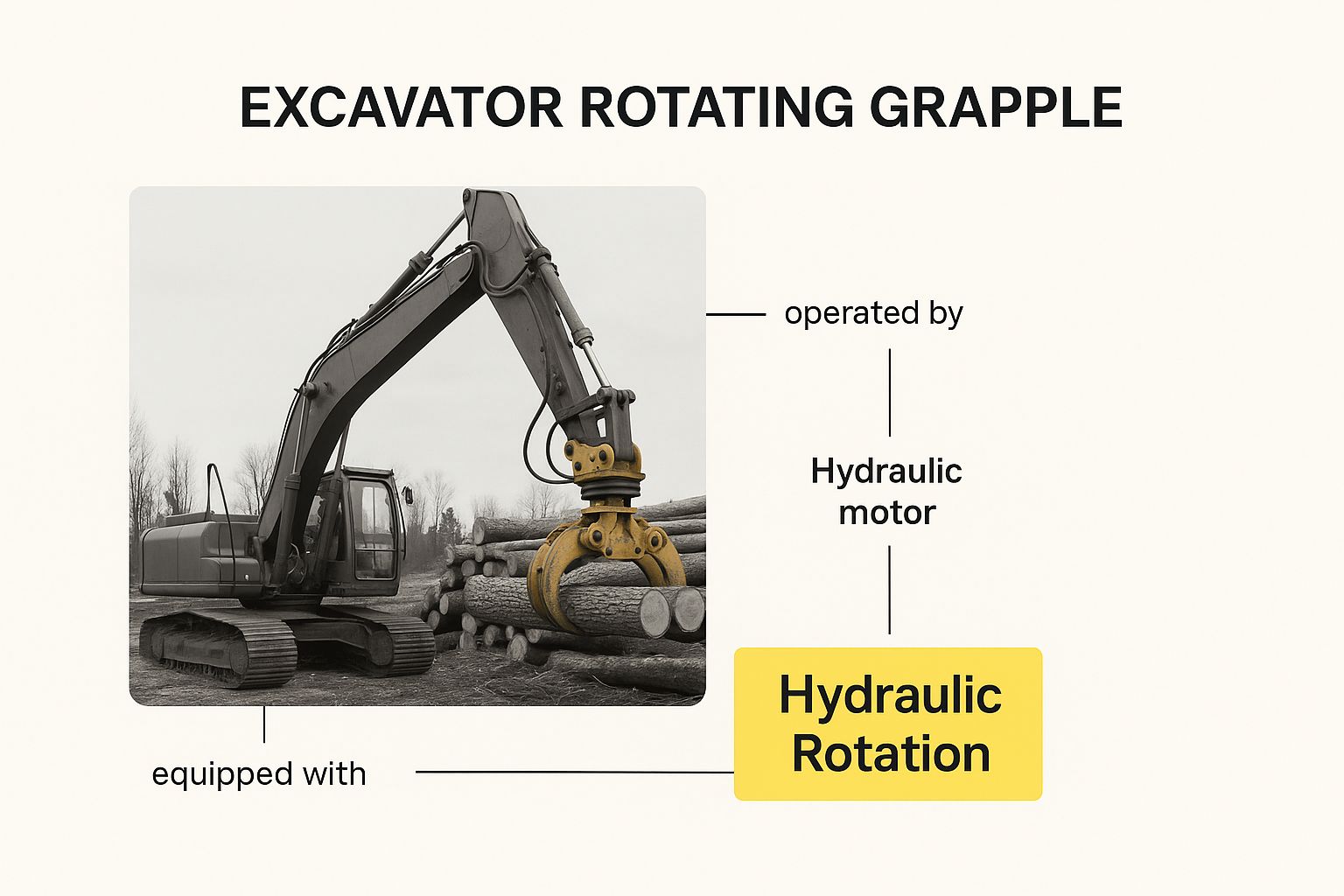

This image shows just how much more efficient an excavator can be on a logging site thanks to hydraulic rotation.

The takeaway here is simple: being able to position the grapple without moving the entire machine saves a massive amount of time and fuel.

This level of engineering allows a single machine to do the work of several, sorting, loading, and placing materials with incredible accuracy. It's a true force multiplier on any project, especially in rough terrain where you need all the stability and control you can get.

When you pair this type of advanced attachment with the right machine, the results are even more impressive. For work in wetlands, swamps, or marshlands, combining a rotating grapple with one of our specialized amphibious hydraulic undercarriages creates a rig that can perform where others simply cannot. The rock-solid stability of the undercarriage allows the operator to use the grapple's full range of motion and lifting power safely.

What Can You Do With It? Real-World Applications

A rotating grapple truly starts to shine once it gets its tines dirty on a real job site. This is where its blend of raw power and nimble control moves from a spec sheet into a genuine problem-solver. Across demolition, environmental work, and utilities, this attachment turns complicated, frustrating tasks into surprisingly straightforward work.

The magic is in how it lets an operator handle materials with almost surgical precision. Instead of constantly repositioning the entire multi-ton excavator just to get the right angle, the operator can simply turn the grapple. This is not just a minor convenience. It is a massive advantage in time, fuel, and wear and tear on the machine.

Demolition and Material Sorting

Picture a typical demolition site: a chaotic jumble of concrete, twisted steel, and other debris. The big challenge here is separating valuable materials, like steel rebar and I-beams, from the worthless rubble. Trying to do this with a standard bucket is a clumsy, slow-moving nightmare.

This is where a rotating grapple changes the game.

- Pinpoint Sorting: Operators can carefully sift through debris piles, using the tines to pluck out tangled metal and set it aside from concrete fragments.

- Smarter Loading: With 360-degree rotation, you can orient the load perfectly for dropping it into a haul truck. This means packing more material into each load and spilling less on the ground.

- A Safer Site: By sorting and stacking materials cleanly, the grapple helps keep the work area organized and safe, cutting down on hazards from unstable debris piles.

Land Clearing and Dredging

When you are clearing land or dredging, especially in sensitive wetlands or along coastlines, the job often involves wrestling with submerged obstacles like logs, stumps, and large rocks. This is tough work, often calling for specialized machines like amphibious excavators. A rotating grapple is the ideal partner for this kind of demanding environment.

The grapple makes short work of these obstacles. It can reach down into the water to get a firm grip on a heavy, waterlogged tree and pull it out cleanly. For shoreline stabilization, the rotational control lets an operator place riprap stones just right, fitting them together like puzzle pieces to build a stronger, more effective wall against erosion. You simply cannot get that level of precision with a bucket.

A rotating grapple turns an amphibious excavator into an incredible tool for environmental restoration. It can selectively remove invasive plants or place new habitat structures with very little disturbance to the surrounding ecosystem.

For specialized projects in these sensitive areas, looking into amphibious excavators for rent can give you the right machine for the job without the major capital outlay.

Pipeline and Utility Work

Handling huge, heavy sections of pipe is a high-stakes game where one slip can be disastrous. An excavator rotating grapple provides the firm grip and fine-tuned control needed to lift, move, and gently set pipeline segments into a trench. The biggest win here is that it dramatically reduces the need for crew members to be anywhere near a heavy suspended load.

From unloading trucks to lining up pipe sections for welding, this attachment streamlines the whole workflow. Its ability to gently rotate and nudge a multi-ton pipe into perfect alignment speeds up the entire installation while making the site significantly safer for everyone involved.

To see how this attachment adds value across different sectors, let's look at a quick breakdown.

Excavator Rotating Grapple Applications by Industry

This table highlights the primary tasks and benefits of using a rotating grapple across different industrial sectors.

| Industry | Primary Task | Key Benefit of Rotation |

|---|---|---|

| Demolition | Sorting rebar, steel, and concrete | Allows for precise picking and sorting of mixed materials, increasing recycling value. |

| Land Clearing | Removing stumps, logs, and boulders | Enables grabbing and maneuvering awkward objects from any angle without repositioning the excavator. |

| Forestry | Loading logs and clearing brush | Optimizes truck loading by aligning logs perfectly, maximizing payload and reducing loading time. |

| Dredging | Removing submerged debris and placing riprap | Provides fine control for underwater work and precise placement of erosion control materials. |

| Utilities | Handling and placing large pipes | Ensures safe and accurate placement of heavy pipeline sections, improving alignment and crew safety. |

As you can see, the ability to rotate the attachment is not just a feature. It is the core advantage that boosts efficiency and safety, no matter the industry.

Driving Profitability and Safety on Your Job Site

Looking beyond the technical specs, the real measure of an excavator rotating grapple is what it does for your bottom line and the safety of your crew. This is not just another attachment. It is a strategic investment that pays back through better efficiency, lower operating costs, and a much safer work environment. The precision you gain when handling materials translates directly into real-world productivity gains.

The first thing you will notice is a huge jump in operational efficiency. Think about it: an operator can grab, twist, and place materials without constantly moving the entire excavator. All that wasted movement is eliminated. This dramatically speeds up everything from sorting demolition debris and loading trucks to placing riprap on a shoreline, helping you wrap up projects faster.

Boosting Your Return on Investment

Every minute saved on a job site is money in your pocket. A rotating grapple fine-tunes your workflow in a few key ways, creating a clear and direct path to a solid ROI.

- Shorter Cycle Times: Combining a powerful grip with 360-degree rotation makes for incredibly smooth material handling. Jobs that used to take multiple repositioning maneuvers can now be done from a single spot.

- Reduced Fuel Burn: When the machine moves less, it burns less fuel. It is that simple. Across a big project, those fuel savings really add up, cutting your overhead and shrinking your environmental footprint.

- Do More with Less: A single excavator with a rotating grapple can sort, load, clear, and place materials. It essentially does the work of several machines, meaning you need less specialized equipment on site.

Over the past two decades, excavator grapples with hydraulic rotation have completely changed how we handle heavy materials. That continuous 360-degree spin gives operators pinpoint control over the payload's orientation, cutting out the time spent repositioning for every single lift. This leads to serious efficiency gains, with cycle times often cut by up to 30%. On large-scale projects, that means significant fuel savings and fewer emissions. You can dig into more data on this industry shift and the impact of global grapple technology.

Creating a Safer Work Environment

Nothing is more important than safety, and the precise control you get from a rotating grapple is a game-changer. It drastically reduces the risks that come with moving heavy, awkward, or unstable loads.

The ability to carefully orient and place materials reduces the danger of swinging loads and prevents the creation of unstable, hazardous debris piles. This level of control keeps ground personnel safer and the entire work area more organized.

On a related note, when moving valuable assets like your excavator and its attachments between sites, solid transportation risk management strategies are crucial. Your investment in the right tool is only protected if it gets to the job site in one piece.

In the end, the excavator rotating grapple makes a powerful case for any manager focused on operational excellence, a strong ROI, and an unwavering commitment to safety.

How to Choose the Right Rotating Grapple

Picking the right rotating grapple for your excavator is not just about buying another attachment. It is about making a smart investment that directly impacts your performance, safety, and bottom line. Get it right, and you boost productivity. Get it wrong, and you are looking at poor efficiency, wasted fuel, and even dangerous equipment failures.

Before you start browsing grapple models, you need to look at your own machine first. The biggest mistake people make is buying an attachment without fully understanding their excavator's capabilities. This oversight can lead to an underpowered tool or, even worse, costly damage to your carrier.

Matching the Grapple to Your Excavator

Think of your excavator and its grapple as a team. For that team to work effectively, the grapple must be a perfect match for your machine's weight class and hydraulic system. It is a classic case of balance, you need enough power to get the job done without compromising the machine's stability.

Here are the non-negotiables you need to verify:

- Excavator Weight: Your grapple's weight must be well within the excavator's safe operating capacity. Bolting on a grapple that is too heavy can make the entire machine dangerously unstable, a major risk on uneven ground or when working with amphibious excavators in soft terrain.

- Operating Pressure: Every grapple is built to operate within a specific hydraulic pressure range, measured in PSI. You must make sure your excavator’s hydraulic output matches what the grapple needs to deliver the clamping and rotation force you are paying for.

- Hydraulic Flow Rate: Measured in gallons per minute (GPM), flow rate dictates how fast your grapple opens, closes, and rotates. A mismatch here will leave you with a sluggish, frustratingly slow attachment that kills your cycle times.

Build Quality and Durability Features

Once you have sorted out the compatibility specs, it is time to dig into the grapple's construction. In tough jobs like demolition or dredging, durability is not a luxury, it is a requirement. A well-built grapple will last longer and keep you out of the repair shop.

Look for signs of smart engineering and high-quality materials. Hardened steel is a must, especially on high-wear parts like the jaw tines and pivot pins, as it stands up to constant abrasion and impact. Also, pay close attention to how the hydraulic lines are protected. Exposed hoses are just waiting to get snagged or crushed, which means immediate downtime and messy fluid leaks.

A well-designed excavator rotating grapple will have its hydraulic hoses and fittings shielded or strategically routed to minimize exposure. This small detail can save you thousands in repairs and lost productivity.

Choosing the Right Tine Design

Finally, the style of the grapple’s tines dictates what kind of material it can handle best. Your choice comes down to your primary application, and the two most common designs you will see are bypass and butt tines.

Bypass tines are designed so the jaws interlock or overlap when fully closed. This makes them perfect for grabbing fine, loose materials like brush, scrap, or other small debris that might slip through other jaw types.

On the other hand, butt tines (or clam tines) have tips that meet flush with each other. This creates a powerful, solid grip that is ideal for securing bulky, uniform objects like logs, pipes, or chunks of concrete.

Essential Maintenance for Maximum Uptime

A well-maintained excavator rotating grapple is not just an attachment, it is your key to reliability, profitability, and safety on the job site. The secret to keeping it that way is proactive maintenance. A few minutes of prevention can save you from unexpected breakdowns, lost operational hours, and costly repairs that could have been avoided.

Think of it as a pre-flight check for your heavy equipment. A pilot would not dream of taking off without a thorough inspection, and the same discipline should apply to your grapple. That small time commitment up front is what separates a smooth, productive day from a project-halting headache.

The Daily Inspection Checklist

Before firing up the machine for a shift, a quick walk-around is non-negotiable. This simple routine focuses on the areas most prone to wear and tear.

- Hydraulic Hoses and Fittings: Scan every hydraulic line for leaks, cracks, or signs of abrasion. What looks like a minor drip today can quickly become a major hydraulic failure, leading to lost fluid, system contamination, and a dead stop in your workflow.

- Tines and Welds: Give the tines a close look. Are there any visible cracks, bends, or signs of excessive wear? Do not forget to check the main frame, paying special attention to the welds where the tines and mounting points connect. This is where structural fatigue often shows up first.

- Pivot Pins and Bushings: Check that all pivot pins are secure and have adequate lubrication. If bushings are worn or pins are loose, it puts a ton of stress on the entire grapple structure, setting it up for premature failure.

Of all the maintenance tasks, proper lubrication is king. Regularly greasing every pivot point and the rotator mechanism is the single most effective way to cut down on friction, prevent wear, and keep the attachment moving just as it should.

A consistent maintenance schedule is not an expense. It is an investment in uptime. Keeping your equipment in top condition ensures it is always ready to tackle the demands of dredging, demolition, or land reclamation projects.

Following these simple steps will go a long way in keeping your excavator rotating grapple running safely and efficiently. When you run into more complex issues or it is time for scheduled servicing, Wilco Manufacturing provides the expert support you need. You can see our commitment to equipment performance and longevity in our Hydratrek service options.

Frequently Asked Questions

When you are looking to add an excavator rotating grapple to your fleet, a few key questions always come up. Whether you are a project manager weighing the investment or an operator thinking about how it handles, getting solid answers is crucial. Let's tackle some of the most common ones.

Can a Rotating Grapple Be Fitted to Any Excavator?

That is a common first question, and the short answer is no. You cannot just slap a rotating grapple on any machine and expect it to work. Compatibility is everything, and it all comes down to the specs of your carrier.

You must match the grapple to the excavator's weight class, its hydraulic system pressure (PSI), and the hydraulic flow rate (GPM). Putting a grapple that is too heavy on a small excavator is a recipe for instability. If the hydraulic flow or pressure is off, you will get sluggish, weak performance. Always consult with an equipment specialist to make sure you are getting a safe and productive match.

What Is the Main Difference Between a Rotating Grapple and a Fixed Grapple?

The game-changer is the 360-degree hydraulic rotation. Think of it like the difference between your arm and your wrist.

A standard fixed grapple just opens and closes, locked in line with the boom. To grab something at an odd angle, you have to move the entire excavator. That means more time, more fuel, and more wear and tear on the machine.

A rotating grapple gives the excavator a "wrist." The operator can twist and turn the grapple to pick up, sort, and place materials from almost any angle without constantly repositioning the carrier. This single feature makes a world of difference in precision and speed.

How Does a Rotating Grapple Improve Job Site Safety?

This is a big one. A rotating grapple boosts job site safety by giving the operator far more control over the load.

Being able to precisely orient a log, a steel beam, or a chunk of concrete means you are less likely to have something slip or swing uncontrollably. Those kinds of accidents are unfortunately common.

It also helps keep the entire site tidier and safer. You can neatly sort and stack materials, which reduces tripping hazards and prevents unstable piles of debris from forming. Plus, because the operator is not constantly repositioning the whole machine, there is less risk of incidents in crowded work zones.

For expert guidance on selecting the right attachments for your amphibious equipment, trust the team at Wilco Manufacturing. Explore our solutions and see how our expertise can benefit your next project by visiting us at https://wilcomfg.com.