When you're staring down a complex dredging, material handling, or environmental cleanup project, the answer isn't always a bigger machine. More often, it's a smarter attachment. The clamshell bucket for excavators is one of those specialized tools that can completely change how a team tackles a job where precision is everything. This guide is for project managers and decision-makers who need to get the job done right, on time, and on budget.

Boosting Project Efficiency with the Right Attachment

Think of a standard digging bucket. It's built for brute force, for breaking ground. A clamshell bucket, on the other hand, operates more like a giant mechanical claw. It's all about finesse.

This unique two-jaw design gives you the control needed for tasks that would leave conventional equipment fumbling. Its vertical grabbing motion is perfect for lifting loose materials like sand, silt, and gravel with almost no spillage, making it an absolute must-have in certain industries.

The real magic happens when you pair a clamshell bucket with an amphibious excavator, like the ones we build here at Wilco Manufacturing. This combination lets operators work in swamps, rivers, and coastal areas, places that are totally off-limits to traditional machinery. The amphibious undercarriage provides a stable platform on soft ground, while the clamshell does the delicate work of scooping material from below the water's surface. This is a game-changer for projects that require working directly in sensitive aquatic environments.

Key Advantages in Challenging Environments

The payoff for using this specialized attachment becomes incredibly clear in sensitive or hard-to-reach locations. Project managers in a few key sectors depend on this tool to solve common challenges.

- Environmental Cleanup: The precise control lets crews carefully remove contaminated soil or sludge from wetlands without churning up the surrounding ecosystem.

- Dredging Operations: It allows for targeted sediment removal to maintain channel depth or clear blockages, all with surgical accuracy.

- Material Handling: Loading and unloading barges with aggregate or riprap becomes faster and cleaner, cutting down on cycle times and preventing costly material loss.

For decision-makers in construction, dredging, and land reclamation, knowing how to properly equip your machines is the first step toward greater productivity. A clamshell bucket isn't just another accessory; it's a strategic investment in getting the job done right.

This guide will walk you through everything you need to know about the clamshell bucket, from its basic mechanics to advanced operating techniques. By understanding its true potential, you can set your team up for success.

You can also discover more about other popular Wilco Marsh Runner attachments and how they solve specific industry problems. Our goal is to give you the knowledge you need to pick the right tools, so your projects finish on time and on budget.

How a Clamshell Bucket Actually Works

Ever seen a giant mechanical clam scooping up material with surgical precision? That's pretty much what a clamshell bucket for excavator work is like. It's a brilliantly simple yet powerful design, specifically engineered to tackle jobs where a standard digging bucket just won't cut it.

The name gives it away. It has two hinged halves, or shells, that open and shut just like the mollusk it's named after. But here's the key difference: instead of scraping or scooping, a clamshell bucket grabs material with a straight-up vertical motion. This one functional distinction is what makes it so indispensable.

Clamshells are not new; they have been a staple in material handling for a long time, evolving right alongside hydraulic excavators since the early 1900s. With their two powerful, hydraulically operated jaws, they're perfect for grabbing loose materials like sand, gravel, and silt. This makes them a go-to tool in construction, dredging, and marine excavation. You can find more on the evolution of excavator attachments on coherentmarketinsights.com to see how far they've come.

The Core Components and Their Functions

The magic of a clamshell bucket lies in a handful of key parts working together seamlessly. Once you understand them, you see how it gets that incredible control.

-

The Shells (Jaws): These are the two big, bowl-like halves that hold the material. Their shape and size are designed for specific jobs, from lightweight models for soft silt to heavy-duty versions armed with teeth to break through compacted soil or debris.

-

Hydraulic Cylinders: Think of these as the muscles. High-pressure fluid from the excavator's hydraulic system powers these cylinders, forcing the shells to open or clamp shut with immense force. It's this direct hydraulic action that gives an operator such fine-tuned control over the grip.

-

Mounting Bracket (Hanger): This is the heavy-duty connector that links the bucket to the excavator's arm. It's built tough to handle the huge forces of lifting and digging, ensuring the whole assembly stays locked securely to the machine.

Hydraulic Power and Precision Control

The way it works is quite direct. The operator hits the controls, and hydraulic fluid rushes into the cylinders, pushing the pistons. This movement smoothly and powerfully closes the shells, allowing them to bite into a pile of material or clamp down on a load underwater.

To release the load, the process is simply reversed. The hydraulic flow switches, the cylinders retract, and the shells open up, dropping the material right where it needs to go. This controlled release is a game-changer when you're loading a barge or carefully placing rock armor along a shoreline, as it cuts down on waste and ensures pinpoint accuracy.

The real takeaway here is the unmatched control a clamshell offers. Its vertical action avoids the messy sediment disturbance and spillage you often get with a scooping bucket. For any job that demands careful material handling, especially in sensitive areas, it's the clear winner.

This precision is absolutely critical for amphibious excavators operating in rivers, canals, or wetlands. The ability to lower an open bucket, close it around specific sediment, and lift it straight up helps protect water quality and the surrounding ecosystem. It’s this blend of raw power and delicate finesse that makes the clamshell bucket for excavators a cornerstone of modern dredging and environmental work.

Real World Applications for Clamshell Buckets

The true value of a clamshell bucket really comes to life when you see it on a job site. Theory is one thing, but how it performs in the field is what truly matters. This attachment is at its best in situations where you absolutely need precision, minimal disturbance, and efficient material handling, especially when it's attached to amphibious equipment like Wilco’s Marsh Runners.

From keeping our waterways clear to cleaning up fragile ecosystems, the clamshell bucket is a real problem-solver. Its straight-up-and-down digging motion and controlled grip make it the perfect tool for jobs that a standard excavator bucket just can't touch. Let’s dive into a few key areas where this tool really shines.

Precision Dredging in Waterways

Keeping rivers, canals, and harbors open and healthy is a never-ending task. Over time, sediment builds up, and that can choke off water flow, raise flood risks, and make channels too shallow for boats. A clamshell bucket, often called a grab dredger in this line of work, is tailor-made for this.

Unlike other dredging methods that kick up a ton of sediment and muddy the water, the clamshell offers a much cleaner, more surgical approach. You can lower the open bucket right to the bottom, close it around a specific patch of silt or debris, and lift it straight out. This technique dramatically cuts down on turbidity, which is absolutely critical for protecting fish and other aquatic life.

For any project where you need to remove material from a very specific spot, this method is hard to beat. You can find more details on the various equipment for dredging projects on wilcomfg.com to see how different tools are suited for different jobs. The clamshell is the star player where precision is the name of the game.

Imagine an amphibious excavator fitted with a clamshell bucket moving into a shallow canal. It can start removing sediment immediately without needing to build access roads or complex support systems. This setup makes for quick, low-impact maintenance in otherwise hard-to-reach spots.

Efficient Material Handling and Loading

On construction sites and at ports, crews are constantly moving huge volumes of loose materials, think sand, gravel, coal, or riprap. The clamshell bucket is a master at this kind of bulk handling, particularly when loading or unloading barges and hoppers.

Its design, with those two big shells, minimizes spillage, which means more material gets where it’s supposed to go. That efficiency saves money by cutting down on waste and speeding up cycle times. A good operator can also control the release of the material with incredible accuracy, preventing damage to the vessel and ensuring the load is spread out evenly.

Consider a coastal restoration project where crews are placing large, heavy rocks (riprap) to stop shoreline erosion. A clamshell can gently pick up and place these awkward, heavy stones with a level of control a standard digging bucket could never hope to match. That kind of careful placement is essential for building a strong, stable barrier that will stand up to the waves.

Environmental Cleanup and Remediation

Some of the toughest jobs out there involve cleaning up contaminated sites, especially in sensitive areas like wetlands, ponds, or riverbeds. Here, the entire goal is to get the bad stuff out while doing as little harm as possible to the surrounding environment.

The clamshell bucket’s gentle, vertical lift is perfect for this kind of environmental work. It allows crews to carefully scoop out contaminated soil or sludge, layer by layer, without mixing it into clean areas. That precision is everything when you're trying to do a thorough cleanup and stop pollutants from spreading.

A perfect example is a project to clean contaminated sediment out of a protected marsh. A Wilco amphibious excavator can drive right out onto the soft ground without tearing it up. Once it's in place, its clamshell can meticulously remove the targeted material, preserving the delicate root systems of the native plants and protecting the local habitat. It’s a low-impact approach that’s vital for any successful ecological restoration.

How To Choose The Right Clamshell Bucket

Picking the right clamshell bucket for excavator work goes far beyond just matching a size. Think of it this way: the wrong attachment can bring your entire project to a screeching halt, leading to expensive downtime and even creating serious safety risks. The right bucket, however, acts as a natural extension of your machine, making it a critical first step for a successful operation.

To get it right, you have to look at how a few key factors work together. It’s a balancing act between the machine itself, the material you’re moving, and what you’re trying to accomplish. Nailing this balance from the start is the best way to get maximum performance out of your equipment and protect your investment.

Matching The Bucket To Your Excavator

First things first, you have to make sure the bucket and your excavator are a good fit. It might seem obvious, but it’s the most common place where mistakes are made. A bucket that’s too heavy can overload the machine’s hydraulics and make it dangerously unstable, while one that’s too small will kill your productivity.

- Weight and Lifting Capacity: The total weight of the bucket plus its payload cannot exceed the excavator’s safe lifting capacity. This is not a guideline, it's a hard rule. Always check your machine's load chart to prevent a tip-over.

- Hydraulic Flow and Pressure: A clamshell’s hydraulic cylinders are designed for a specific flow rate (GPM) and pressure (PSI). If your excavator can't provide what the bucket needs, you'll get slow, weak performance or, even worse, risk damaging the hydraulic system.

This compatibility check is non-negotiable. It's especially crucial for specialized jobs that require unique machinery, where balance and hydraulics are pushed to their limits. You can get a better sense of how machine specs and attachments pair up by looking at different amphibious excavators for rent.

Analyzing Material And Project Demands

Once you've confirmed the bucket will work with your machine, the next piece of the puzzle is the material you're handling. The stuff you're digging into directly dictates the kind of bucket you need.

For example, if you’re moving light, loose materials like sand or silt, a standard-duty bucket will probably do the job just fine. But if you’re up against dense, abrasive stuff like compacted clay or heavy riprap, you’ll need a heavy-duty bucket built with high-strength steel and reinforced wear plates to handle that kind of punishment.

Actionable Insight: The density, abrasiveness, and consistency of the material dictate the structural integrity required of your clamshell bucket. Always choose a bucket specifically engineered for the type of material you will be moving.

Your project goals also have a major say. A massive dredging project that’s all about moving huge volumes quickly will require a bucket with a much larger capacity than a precision environmental cleanup where careful handling is more important than speed. Defining your objectives upfront will make it much easier to narrow down your choices.

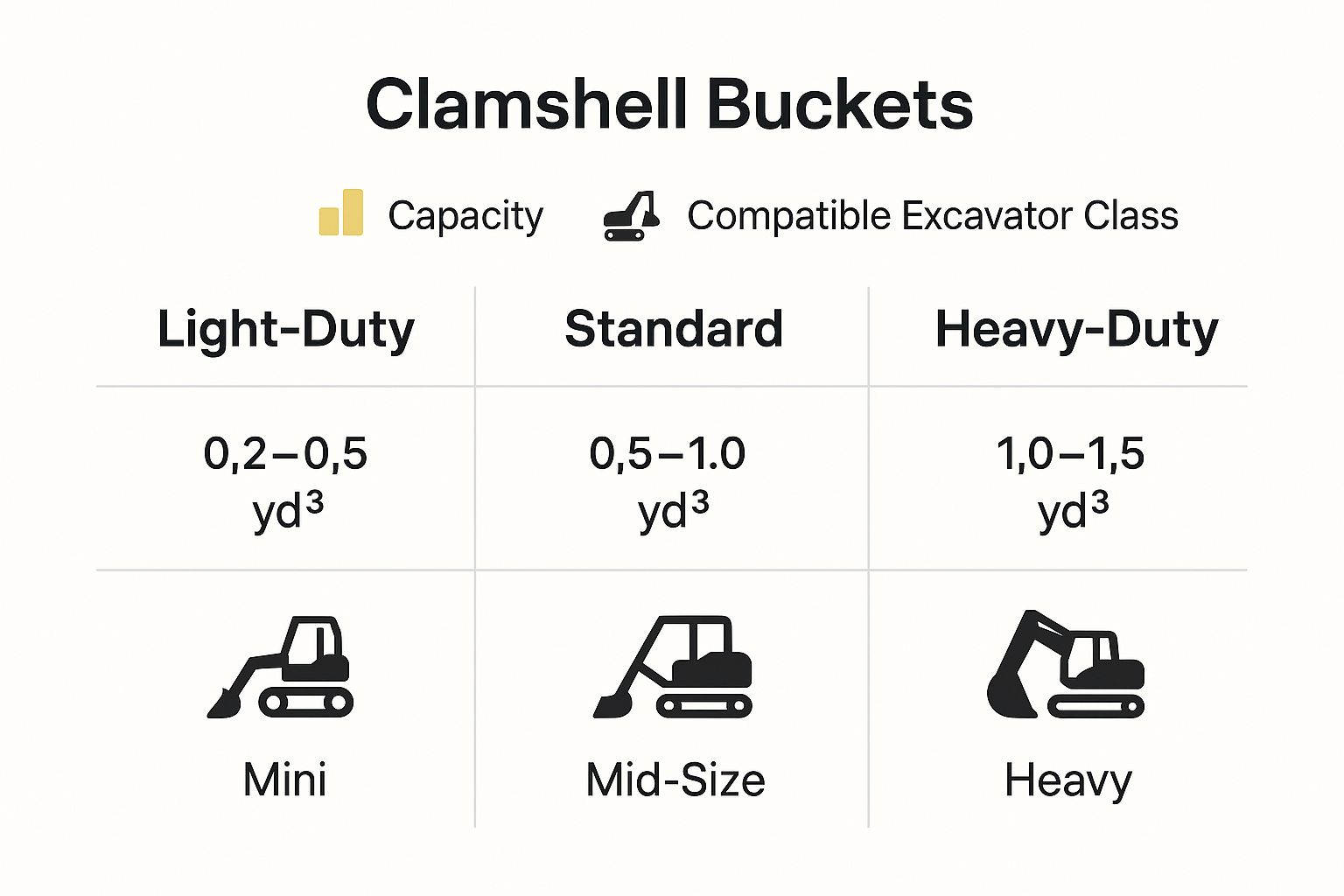

The image below gives you a quick visual guide to how different bucket classes line up with excavator sizes and capacities.

As you can see, a bucket’s duty rating isn't arbitrary. It corresponds directly to its volume and the class of machine needed to run it safely and efficiently.

To make this even clearer, let's break down the common bucket types.

Clamshell Bucket Selection Guide

Choosing the right clamshell bucket is crucial for maximizing efficiency. This table breaks down different bucket types to help project managers match the right attachment to the job at hand.

| Bucket Type | Key Features | Primary Application | Material Type |

|---|---|---|---|

| Standard-Duty | General-purpose build, lightweight design | Digging, backfilling, material handling | Soil, sand, gravel, loose materials |

| Heavy-Duty | High-strength steel, reinforced cutting edges | Dredging, demolition, quarrying | Compacted soil, clay, riprap |

| Environmental | Sealed lips, specialized design to prevent leakage | Contaminated soil removal, sensitive cleanups | Silt, sludge, hazardous materials |

| Re-handling | High capacity, lightweight construction for volume | Loading/unloading barges, stockpiling | Grain, coal, fertilizer, wood chips |

By understanding these distinctions, you can select a bucket that not only fits your excavator but is also perfectly suited for the material and the specific demands of your project.

Consulting With Equipment Experts

While spec sheets and charts give you a great starting point, there's no substitute for experience. The market for excavator attachments is always evolving; it was valued at around USD 1.25 billion in 2023 and is expected to hit USD 2.17 billion by 2032. That growth is fueled by new materials and hydraulic systems designed to do more, faster.

Trying to navigate all these options on your own can be overwhelming. That’s why talking to a specialist like Wilco Manufacturing is a smart final step. Our team lives and breathes this stuff, especially for tough jobs like pipeline work or land reclamation. We can help you look at your project from every angle and recommend a clamshell bucket for your excavator that is a perfect match for both your machine and your goals. That kind of expert advice ensures you get the right tool for the job, saving you time, money, and a world of headaches down the line.

Putting Your Clamshell Bucket to Work: Best Practices and Maintenance

Getting the right clamshell bucket for an excavator is only half the battle. How your team operates and cares for it is what truly unlocks its value on the job site. Smart operational habits and a consistent maintenance routine are the keys to hitting peak performance, keeping your crew safe, and making sure your investment pays off for years to come.

This drive for operational excellence is not just a good idea, it's shaping the entire equipment market. The precision of a clamshell bucket cuts down on material spillage and costly downtime, which has a direct, positive impact on project budgets and schedules. This demand for high-performance, efficient tools is why the global excavator attachments market is expected to climb from roughly USD 8.64 billion in 2025 to USD 13.35 billion by 2032.

Honing Operator Technique for Maximum Efficiency

In the hands of a skilled operator, a clamshell bucket becomes a precision tool. The secret is learning to work with the attachment’s design, not fighting against it. Smooth, controlled actions always outperform aggressive, jerky movements.

Here are a few techniques every good operator should master:

- Position for a Straight Drop: Always set up the excavator so the bucket can be lowered and lifted vertically. Coming at the material from an angle puts a tremendous amount of side-loading stress on the pins and bushings, which is a surefire way to cause premature wear.

- Let Gravity Do the Work: Avoid slamming the shells shut. A much better approach is to let the bucket’s own weight penetrate the material first, then gently close the jaws. This technique gets you a full load while putting minimal strain on the hydraulic system.

- Create an Efficient Cycle: Cut down on swing time by positioning the dump truck or barge as close as you safely can. The fastest way to move material is not about speed; it's about smooth, repeatable cycles that become second nature.

From the Field: The real goal is fluidity. A seasoned operator knows that the most productive cycle has zero wasted motion. Every lift, swing, and release flows into the next, forming a steady rhythm that moves the most material per hour while sipping fuel and saving wear and tear on the machine.

Non-Negotiable Safety Protocols

A safe job site is a productive one. When you're running a clamshell bucket, especially in tricky spots like over water or in a crowded construction zone, following safety rules is absolutely critical.

- Own the Zone: Clearly mark and enforce a safe swing radius around the excavator. No one, no exceptions, should ever enter this area while the machine is running.

- Know Your Limits: Never try to lift more than the excavator's rated capacity. This is especially important when working on barges or soft ground where the machine's stability is already compromised.

- Start with a Walk-Around: Before the first scoop of the day, operators must do a pre-shift inspection. This means checking for hydraulic leaks, making sure all connections are tight, and looking for any visible damage to the bucket or the excavator itself.

A Simple Maintenance Checklist That Works

The best way to avoid expensive downtime is to catch problems before they start. A straightforward, consistent maintenance schedule is your best defense. Think of it like the expert Hydratrek service and support that keeps amphibious machines running smoothly. Your bucket needs that same level of routine care to stay in top shape.

Daily Checks (Before You Start):

- Quick Visual: Walk around the bucket. Look for any cracks, dents, or signs of stress on the shells and hanger.

- Hose Check: Scan all hydraulic lines for leaks, cracks, or spots that look worn or abraded.

- Grease the Joints: Hit all the grease points on the pins and bushings. This simple step prevents friction and keeps parts from seizing up.

Weekly Checks:

- Inspect the Edges: Take a close look at the teeth or cutting edges. If they’re heavily worn or damaged, rotate or replace them to keep digging performance sharp.

- Tighten Up: Check that all the bolts and nuts on the bucket and its mounting bracket are torqued to spec.

- Look for Weeping Seals: Examine the hydraulic cylinders for any hint of fluid leaking from the seals. A little "weep" is often the first sign of a seal that's about to fail.

Your Partner in Specialized Excavation

The clamshell bucket is so much more than just another excavator attachment. It's a purpose-built tool, a problem-solver designed specifically for some of the toughest jobs out there. As we've seen, it plays a vital role in challenging environments like wetlands and waterways, where precision and power are paramount.

For any project manager working in or near water, getting the equipment right is not just a detail, it's the bedrock of the entire operation.

Building a Foundation for Success

True success in specialized excavation is not just about having the right hardware. It’s also about smart project planning and managing risk from every angle. Part of that bigger picture involves protecting your business. For instance, understanding the ins and outs of professional liability insurance for contractors is just as important as choosing the right bucket for the job. Taking a comprehensive approach is what ensures a project is not only efficient but also secure.

When you work with a team like Wilco Manufacturing, you’re not just buying heavy equipment. You’re gaining an ally, one that’s committed to engineering the perfect solution for your specific project, whether it's dredging, cleanup, or complex material handling. We provide the tough, reliable amphibious gear needed to tackle impossible terrains and the expertise to make sure it performs perfectly every single time.

Partnering with an experienced manufacturer means your equipment is backed by decades of field-tested knowledge. It's the difference between simply buying a machine and truly investing in a successful project outcome.

Don't leave your equipment choice to chance on your next dredging, environmental cleanup, or material handling project. Reach out to our team of experts today. Let's talk through your specific needs and figure out how our amphibious solutions can help you succeed where others simply can't.

Frequently Asked Questions

When it comes to putting a clamshell bucket to work on your excavator, a few questions always seem to pop up. Let's tackle the most common ones to help you make the right calls for your project.

What’s The Main Difference Between A Clamshell And A Digging Bucket?

Think of it like this: a standard digging bucket is a spade, built for breaking new ground. It uses a single, tough cutting edge to scrape, dig, and scoop up dense earth. It’s all about brute force and excavation.

A clamshell bucket, on the other hand, is more like a set of giant, precise hands. Its job is not to break ground, but to handle loose or submerged material. The two hinged jaws (or "shells") close together to grab and lift, which is perfect for moving things vertically with minimal mess. This is why it's the go-to tool for dredging or loading barges, where you need control and containment, not raw power.

Can I Put A Clamshell Bucket On Any Excavator?

Absolutely not. This is one area where you cannot just "make it fit." Compatibility is a huge deal for both safety and getting the job done right. The excavator's size, its operating weight, and most importantly, its hydraulic system have to be a perfect match for the bucket you want to use.

Before you even think about attaching one, you have to compare your excavator's specs, especially hydraulic flow and pressure, with what the bucket needs to run. We always recommend talking to an expert, like our team here at Wilco, to guarantee a safe and efficient setup. A mismatch is a recipe for disaster. You could end up with terrible performance, an unstable machine, or even serious damage to your equipment.

How Do I Know What Size Clamshell Bucket I Need?

Choosing the right size is a balancing act. You have to weigh three key factors to land on the sweet spot for efficiency and safety.

Get these three things in sync:

- Material Density: What are you moving? Heavy, dense materials like wet sand or riprap demand a lot more lifting power than lighter stuff like silt or wood chips. You might need a smaller bucket for dense material just to stay within your excavator's safe lifting limits.

- Required Production Rate: How fast do you need to work? A bigger bucket moves more material per cycle, which can speed up your project. But that only works if your excavator can handle the heavier load without slowing down or becoming unstable.

- Excavator Lifting Capacity: This is the hard limit you cannot ignore. The total weight of the bucket plus a full load of material can never exceed the excavator's maximum safe lifting capacity. Always check the machine's load chart.

Going too big can overload your excavator, making it dangerously top-heavy, which is especially risky on a barge or uneven ground. On the flip side, a bucket that’s too small will cripple your productivity and drag out your timeline.

When your project demands precision in tough spots, having the right gear is everything. For expert advice on pairing the perfect clamshell bucket and amphibious excavator for your job, you can trust Wilco Manufacturing.

See our world-class amphibious equipment solutions by visiting us at https://wilcomfg.com.