Have you ever seen an excavator pick up a large log or a piece of concrete with remarkable precision? The secret is often a simple but brilliant attachment: the excavator thumb bucket. This tool is exactly what it sounds like, a hydraulic "thumb" that works against the bucket, giving the machine a powerful, secure grip.

This attachment fundamentally changes what an excavator can do. Instead of only scooping loose material, it can now securely clamp down on and handle all sorts of materials, from awkward logs and boulders to messy demolition debris. It gives the operator a level of control that is simply impossible with a standard bucket alone, making it an invaluable tool for industries like construction, dredging, and land reclamation.

What an Excavator Thumb Bucket Actually Does

Think of it this way: try picking up a bottle of water without using your thumb. It’s clumsy and inefficient. The same principle applies to an excavator. The thumb provides the dexterity needed to grasp, sort, and place objects with remarkable precision.

Without one, an operator is stuck scooping and pushing. With a thumb, that same machine becomes a multi-purpose tool capable of tackling complex handling jobs that would otherwise require additional equipment or a ground crew, saving both time and money.

It is no surprise that this attachment is in high demand. The global market for excavator thumbs was valued at approximately USD 423.7 million, a number proving just how essential these tools have become. Contractors in construction, land clearing, and mining see a clear return on investment. You can learn more about the excavator thumb market size and forecast to see how the industry is moving toward getting the most out of every machine.

Expanding Your Machine's Capabilities

Adding a thumb to an excavator's arsenal opens up a whole new world of tasks, which has a direct impact on job site productivity. Suddenly, one machine can handle multiple project stages, from initial clearing to final cleanup.

This versatility is a game-changer, especially on challenging sites like wetlands or unstable slopes where minimizing machine movement is critical. For specialized equipment like Wilco's amphibious excavators tackling dredging or environmental restoration, a thumb is not just a helpful accessory, it is a core part of the operation.

Here’s what an operator can do with that added grip:

- Securely move awkward materials like large rocks, tree stumps, and concrete rubble.

- Precisely place items, such as setting riprap to stabilize a shoreline or laying pipes in a trench.

- Sort and load debris during demolition, separating recyclable materials from waste on the fly.

- Dramatically improve job site safety by preventing heavy, unstable loads from shifting or falling.

Choosing Between Mechanical and Hydraulic Thumbs

When you are ready to add a thumb to your excavator, the first big question is: mechanical or hydraulic? This is not just a minor detail. It is a decision that will shape your machine's capabilities, your crew's efficiency, and the types of jobs you can confidently take on. The two types work very differently, and each has its place on the job site.

The Mechanical Thumb: Simple and Sturdy

A mechanical thumb, sometimes called a "stiff arm," is the straightforward, no-frills option. Think of it like a fixed wrench. You set it in one of a few positions using a pin and a strut, and it stays there until you get out of the cab to move it yourself.

This design makes it a solid choice for repetitive work where you are handling similarly sized objects over and over. For example, if a project involves clearing logs or loading uniform chunks of rock all day, a mechanical thumb is a reliable workhorse that gets the job done without a lot of complexity.

The Hydraulic Thumb: Precision and Power

On the other end of the spectrum is the hydraulic excavator thumb. This is the high-performance, precision tool. It connects directly to your excavator's hydraulic system, giving you full, fluid control right from the joysticks inside the cab. You can open, close, and adjust the grip on the fly.

This level of control is a game-changer for complex jobs. Imagine delicately sorting through demolition debris, carefully placing riprap on a shoreline, or gently maneuvering a pipe into place. For that kind of work, you need the ability to apply just the right amount of pressure from the perfect angle, and that is exactly what a hydraulic thumb delivers.

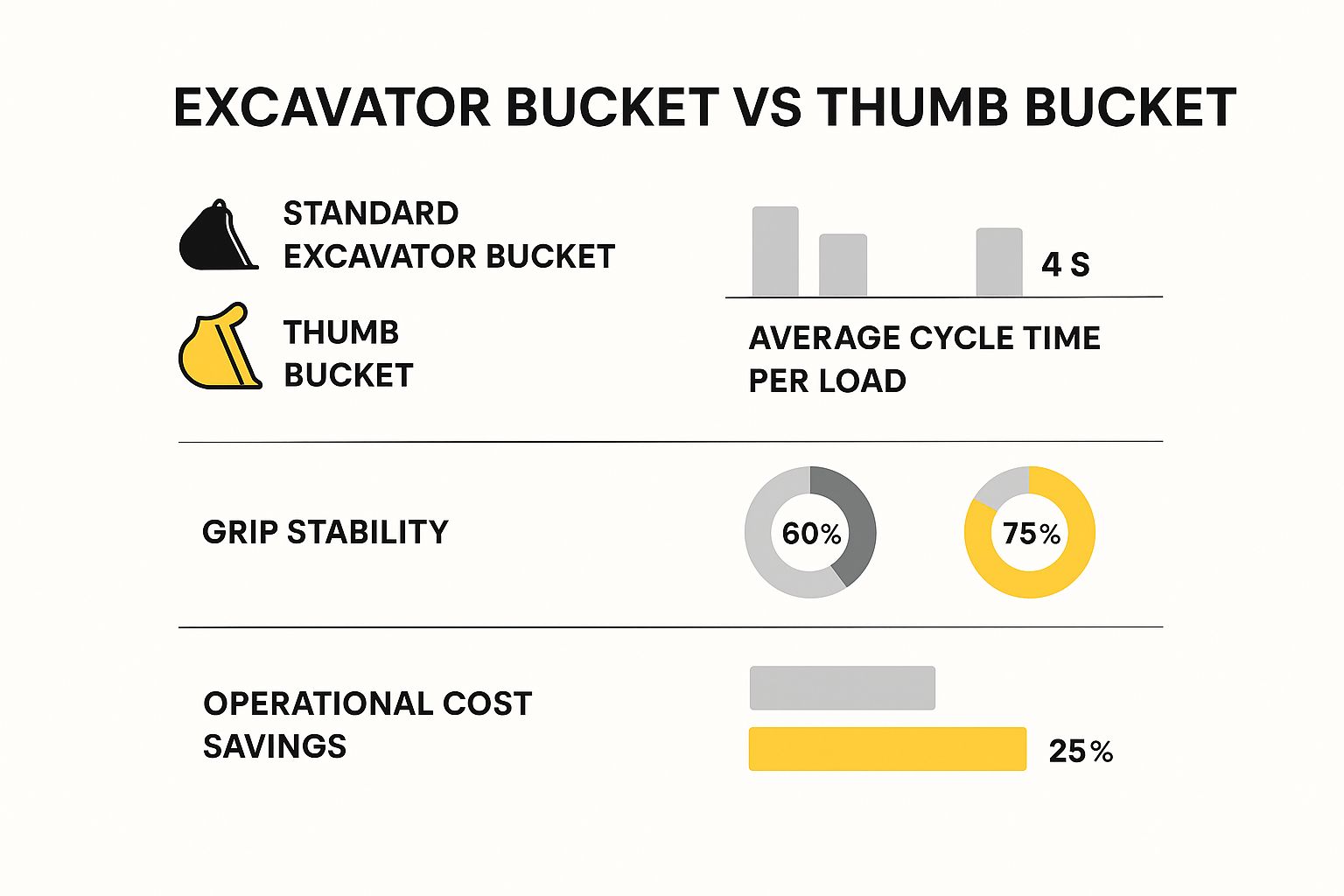

A Head-to-Head Comparison

To make the decision clearer, let's break down the key differences between these two workhorses. The right choice often comes down to balancing cost, control, and the specific demands of your projects.

Mechanical vs Hydraulic Excavator Thumb Comparison

| Feature | Mechanical Thumb | Hydraulic Thumb |

|---|---|---|

| Control | Manual; requires operator to exit cab to adjust | Fully adjustable from the cab using hydraulics |

| Precision | Low; limited to 2-3 fixed positions | High; offers a full range of motion and variable grip |

| Versatility | Best for uniform, repetitive tasks | Excellent for varied, complex, and delicate jobs |

| Efficiency | Slower; downtime needed for adjustments | Faster cycle times; adjustments are instant |

| Upfront Cost | Lower | Higher |

| Maintenance | Minimal; fewer moving parts | More complex; requires hydraulic line maintenance |

| Safety | Good; provides a basic grip | Superior; a secure, adjustable grip reduces drop risk |

Ultimately, a mechanical thumb offers a cost-effective solution for basic gripping, while a hydraulic thumb is a true investment in productivity and versatility for more demanding operations.

Making the Final Call

So, which one is right for you? It really boils down to your day-to-day work and your budget.

The real trade-off is between upfront cost and long-term operational efficiency. A mechanical thumb saves money initially, but a hydraulic thumb saves time and labor on every single cycle, which adds up fast.

Here’s a simple way to think about it:

- Go with a mechanical thumb if: Your jobs are fairly consistent, like basic land clearing or loading predictable materials. Budget is your top priority, and you do not mind the occasional downtime to make a manual adjustment.

- Go with a hydraulic thumb if: Precision and speed are the name of the game. You are constantly handling materials of different shapes and sizes, and every minute of downtime costs you money.

For specialized operators, particularly those in sensitive environments like pipeline installation or shoreline restoration, the enhanced safety and control of a hydraulic thumb is not just a luxury. It is essential for getting the job done right.

The Real-World Benefits of Using a Thumb Bucket

Adding a thumb to your excavator is not just a minor upgrade, it is a game-changer for your job site. Think of it as giving your machine a hand. This simple addition transforms a basic digging tool into a multi-functional workhorse, and the practical benefits in efficiency, safety, and versatility become obvious almost immediately.

The biggest and most immediate impact is on safety. Trying to balance a heavy log, a chunk of concrete, or a large rock in a standard bucket is always precarious. A thumb provides a secure, positive grip that clamps down on the material, drastically reducing the risk of an accidental drop that could injure someone on the ground or damage nearby property. That extra control is priceless, especially when working in tight quarters or around delicate structures.

Boosting Productivity and Versatility

The jump in productivity is just as impressive. Without a thumb, an operator often has to reposition the entire machine multiple times or wait for another piece of equipment to help move material. An excavator thumb bucket lets one machine seamlessly switch between digging, clearing, sorting, and loading, all without stopping to swap out attachments.

This all-in-one workflow shaves off machine hours, lowers labor costs, and helps you complete projects faster. Suddenly, a single operator can handle tasks that might have previously required an entire ground crew, which directly improves your bottom line.

By enabling one machine to perform multiple roles, an excavator thumb bucket reduces the need for additional specialized equipment on site, leading to significant cost savings in transport and rental fees.

This newfound versatility also opens the door to more types of work. An excavator that can only dig has its limits. But with a thumb, that same machine becomes the perfect tool for a host of different jobs.

- Demolition Projects: Operators can carefully dismantle structures, separating rebar from concrete and loading out debris with pinpoint control.

- Landscaping and Forestry: Moving boulders, placing logs for a retaining wall, or ripping out stumps and brush becomes a straightforward, manageable task.

- Environmental Cleanup: A thumb is perfect for pulling debris from waterways or sorting through contaminated soil, a common job for specialized amphibious excavators.

This adaptability makes your equipment far more valuable across the board. Whether you’re tackling shoreline restoration or need specific equipment for dredging, the added function means your machine is always ready for whatever the job throws at it. In the end, these benefits lead to a better return on your investment, quicker project turnaround, and a safer, more efficient work environment for everyone.

How to Select the Right Thumb for Your Excavator

Picking the wrong thumb for your excavator is not just an inconvenience. It is a recipe for costly downtime, sluggish performance, and even serious safety risks on site. The right choice is about much more than a simple fit. It’s about creating a perfect partnership between your attachment, your machine, and the specific jobs you tackle every day.

Think of it this way: a well-matched thumb feels like a natural extension of your excavator's arm. A poor match, on the other hand, will fight you at every turn. That is why the selection process has to start with an honest look at your excavator’s own specifications. Pushing a machine past its limits is a surefire way to cause mechanical stress or hydraulic failure.

Check Machine Compatibility First

Before you even start browsing thumb models, you need to have your excavator's vital statistics handy. The thumb’s overall weight and size must be a good match for your machine's class. A thumb that is too big and heavy will throw off the excavator’s balance and put dangerous strain on the boom and stick. Go too small, and you will lack the strength and reach to do the job properly.

Next, look at the width. The thumb needs to work in harmony with your bucket. If it is too narrow, you will struggle to get a solid grip on wider loads like logs or debris. If it is too wide, it can interfere with the bucket's teeth when you are digging. The goal is a perfect sync-up for a secure, confident grip.

And if you’re looking at a hydraulic model, your machine’s hydraulic system is the final piece of the puzzle.

- Hydraulic Flow (GPM): The thumb needs a specific flow rate to move smoothly and predictably. A mismatch here will lead to jerky, frustrating movements.

- Hydraulic Pressure (PSI): Your system has to deliver enough pressure to generate the clamping force needed for heavy materials. Without enough PSI, you will have a weak grip that can't be trusted.

Prioritize High-Strength Construction

Let's be honest, the working environment for an excavator is brutal, especially for amphibious units working in dredging or environmental remediation. Your thumb will be taking a beating from constant impacts, abrasion, and heavy loads day in and day out. This is why high-strength steel construction is not just a nice feature, it is absolutely essential for long-term durability.

A well-built thumb made from hardened, abrasion-resistant steel will withstand the daily grind of gripping rock, concrete, and other rough materials without premature wear or structural failure.

Spending a little more on quality materials upfront saves a fortune in repairs and replacement parts down the road. This focus on durability is a huge reason behind the attachment's growing popularity. In fact, the global market for these attachments is projected to hit USD 180 million by 2033, a clear sign of the industry's demand for tough, efficient gear. You can find more details in this forecast for the excavator thumb market.

By carefully running through these compatibility checks and making tough construction a top priority, you can find an excavator thumb bucket that integrates perfectly with your machine. This ensures you get a tool that performs reliably and makes your entire operation more efficient. For more on how to expand your machine's capabilities, take a look at our guide on the most popular marsh runner attachments.

Keeping Your Excavator Thumb in Fighting Shape

An excavator thumb is a serious investment in your machine's productivity. But like any heavy-duty tool, it needs consistent care to keep performing at its peak. The last thing anyone wants is an unexpected breakdown that brings the whole job to a screeching halt.

A simple, proactive maintenance routine is your best defense. It protects the equipment, keeps your operator safe, and makes sure your excavator is always ready to tackle tough land reclamation or cleanup jobs. Think of it as a few minutes of prevention to save days of cure.

The easiest way to catch small issues before they become major headaches is with a pre-use checklist. This quick walk-around is a small habit that pays huge dividends in uptime.

The Daily Pre-Use Checklist

Before starting the machine, a quick visual and physical check can make all the difference. Here’s what every operator should be looking at each day:

- Inspect Hydraulic Lines: For hydraulic thumbs, give every hose and connection a once-over. You are looking for leaks, cracks, or any signs of rubbing or abrasion. A failing hose means a sudden loss of grip, which is a massive safety hazard.

- Check Welds for Stress: Take a close look at all the weld points on the thumb and its mounting bracket. Keep an eye out for hairline cracks or signs of metal fatigue. These are the early warnings of too much stress.

- Lubricate Pins and Bushings: Grease is cheap, parts are not. Make sure all the grease points on the thumb's pivot pins and bushings are well-lubricated. This is non-negotiable for smooth movement and preventing premature wear.

- Confirm Secure Mounting: Grab the thumb and give it a shake. Are all the bolts and pins holding it to the excavator's stick tight? Loose connections lead to sloppy, unsafe operation and can damage both the thumb and the machine.

Regular maintenance isn’t just about fixing what’s broken. It’s about building reliability. A well-maintained thumb is a tool you can count on, job after job.

Beyond the daily checks, how you operate the thumb plays a huge role in its lifespan. It is critical to avoid side-loading, which puts incredible lateral stress on the thumb's structure. Always line the machine up to grab objects straight on.

Smooth, controlled movements will also go a long way in reducing wear and tear on the pins, bushings, and the entire hydraulic system. When parts do eventually wear out, getting the right replacements quickly is key. Wilco Manufacturing stocks a full line of excavator replacement parts to get you back up and running fast.

Partner with Wilco for Your Equipment Needs

Ultimately, an excavator thumb bucket is more than just an attachment. It is a game-changer for safety and efficiency on any job site. This is especially true when working in tough amphibious environments where standard equipment just will not cut it. Getting the right gear is the key to unlocking your machine's full potential and making your investment pay off.

Here at Wilco Manufacturing, we do not just sell equipment, we engineer real-world solutions. Our attachments are built to withstand the harshest conditions found in dredging, environmental cleanup, and pipeline installation. We bring the hands-on experience needed to match you with the right attachment to boost your machine's performance and help you hit your project targets.

Investing in Proven Solutions

The industry-wide move toward high-performance attachments is not just a hunch. The market for excavator buckets and essential accessories like the excavator thumb bucket was recently valued at roughly USD 1.25 billion. It is projected to climb to USD 2.17 billion by 2032, fueled by major infrastructure projects across the globe. You can dig into more of that data on the excavator bucket market growth on DataIntelo.

This trend highlights just how critical it is to work with a partner who understands both the machinery and the unforgiving environments where it is put to work. Our success is tied to yours, and we are committed to providing the practical knowledge you need to make smart decisions.

Equipping your machine correctly isn't just about finishing a job. It's about improving your bottom line through greater efficiency, enhanced safety, and the versatility to take on more complex projects.

Whether you are in the market for a new machine or need to upgrade your current one, we have the inventory and expertise to guide you. Our fleet of amphibious excavators for rent offers a flexible option for specialized projects, making sure you have the right tool right when you need it. Let our team help you find the perfect equipment solution.

Frequently Asked Questions

When you are looking to add an excavator thumb to your fleet, a few practical questions always come up. Here are the straight answers to the most common inquiries we hear from project managers in construction, dredging, and land reclamation.

Can a Thumb Be Added to Any Excavator?

The short answer is yes, most excavators can be fitted with a thumb. The real question, however, is about compatibility. You cannot just attach any thumb to any machine.

The thumb's size, weight, and hydraulic needs must match your excavator's specifications perfectly. Getting this wrong can lead to poor performance or even damage your equipment. Always check your machine's manual or speak with an expert at Wilco to guarantee a safe and solid fit.

What Is the Main Cost Difference Between Mechanical and Hydraulic Thumbs?

Upfront, mechanical thumbs are the more budget-friendly choice. Their design is simpler with fewer moving parts, which keeps the initial purchase price down. They get the job done for basic, repetitive grabbing tasks.

Hydraulic thumbs, on the other hand, cost more initially because they come with cylinders, hoses, and valves that give you full control right from the cab. While the ticket price is higher, their precision and speed can dramatically boost your efficiency on complex jobs, often leading to a much better return on your investment over time.

How Long Does It Take to Install an Excavator Thumb Bucket?

Installation time really depends on the type of thumb you choose. A simple weld-on mechanical thumb can often be mounted in just a few hours by a skilled welder.

A hydraulic thumb is a different story. It is a more involved process that includes welding mounting plates and plumbing new hydraulic lines. This kind of job can easily take a full day or more and should always be done by a qualified technician to ensure it is safe and functions correctly.

For expert guidance in selecting the right equipment for your challenging projects, trust Wilco Manufacturing. We provide robust, reliable amphibious equipment and attachments engineered for the toughest jobs on earth. Contact us today to discuss your project needs.