When a standard piece of equipment just won't cut it, a long reach excavator rental can be a project-saver. These specialized machines are designed for one primary purpose: to handle digging, dredging, and material moving tasks far beyond the capabilities of a typical excavator. This makes them the go-to solution for jobs that demand serious reach, like deep excavations, waterway maintenance, or demolishing structures from a safe and stable distance.

The core advantage here is access. A long reach excavator lets you complete jobs that would otherwise be impossible or require a complex, inefficient setup with multiple machines. For project managers in construction, dredging, or environmental cleanup, understanding how to leverage this equipment is key to overcoming site challenges.

Why a Standard Excavator Can't Always Do the Job

Imagine you're tasked with clearing sediment from the middle of a wide canal or taking down a building that’s right next to a busy road. A standard excavator just doesn't have the reach to bridge that gap. This is precisely where a long reach excavator shines.

Its extended boom and arm are engineered specifically for these scenarios, giving you the extra distance needed to turn a logistical headache into a straightforward task. This specialized design is often the deciding factor between keeping a project on schedule and facing costly delays.

This need for specialized machinery is a big reason the equipment rental market is booming. The U.S. construction equipment rental market recently surpassed $64.76 billion and is on track to hit nearly $98.29 billion by 2034. This growth shows a clear industry trend: contractors are choosing to rent advanced, versatile equipment to handle complex projects in demolition, mining, and urban development. You can dive deeper into these trends in the full report on the U.S. construction equipment rental market.

Key Benefits of Renting a Long Reach Excavator

Choosing a long reach excavator rental offers more than just extra feet and inches. The strategic advantages it brings to a project can have a real impact on safety, efficiency, and your bottom line.

- Better Site Safety: The ability to position the machine on stable ground, far from the actual work area, is a huge safety win. It keeps your operator and expensive equipment away from unstable soil, deep water, or active demolition zones.

- A Major Productivity Boost: In many cases, a single long reach excavator can do the work that would otherwise require multiple smaller machines. It can also eliminate the need for costly and time-consuming workarounds like building temporary causeways or bringing in barges.

- Precision from a Distance: You might think that more reach means less control, but these machines are surprisingly nimble. Modern long reach excavators offer incredible precision, allowing for accurate digging, grading, and material placement even when the boom is fully extended.

Before we dive deeper, let's break down the fundamental differences between these two machine types.

Standard vs Long Reach Excavator Capabilities

| Feature | Standard Excavator | Long Reach Excavator |

|---|---|---|

| Horizontal Reach | Typically 20-35 feet | Can exceed 100 feet |

| Digging Depth | Generally 15-25 feet | Often 70 feet or more |

| Ideal Applications | General construction, trenching, foundation digging | Dredging, demolition, deep excavation, bank sloping |

| Counterweight | Standard size for balance | Heavier, oversized for stability |

| Primary Advantage | Versatility and power for common tasks | Unmatched access and reach |

This table makes it clear: while a standard excavator is a versatile workhorse, the long reach model is a specialist, built to solve problems of distance and depth.

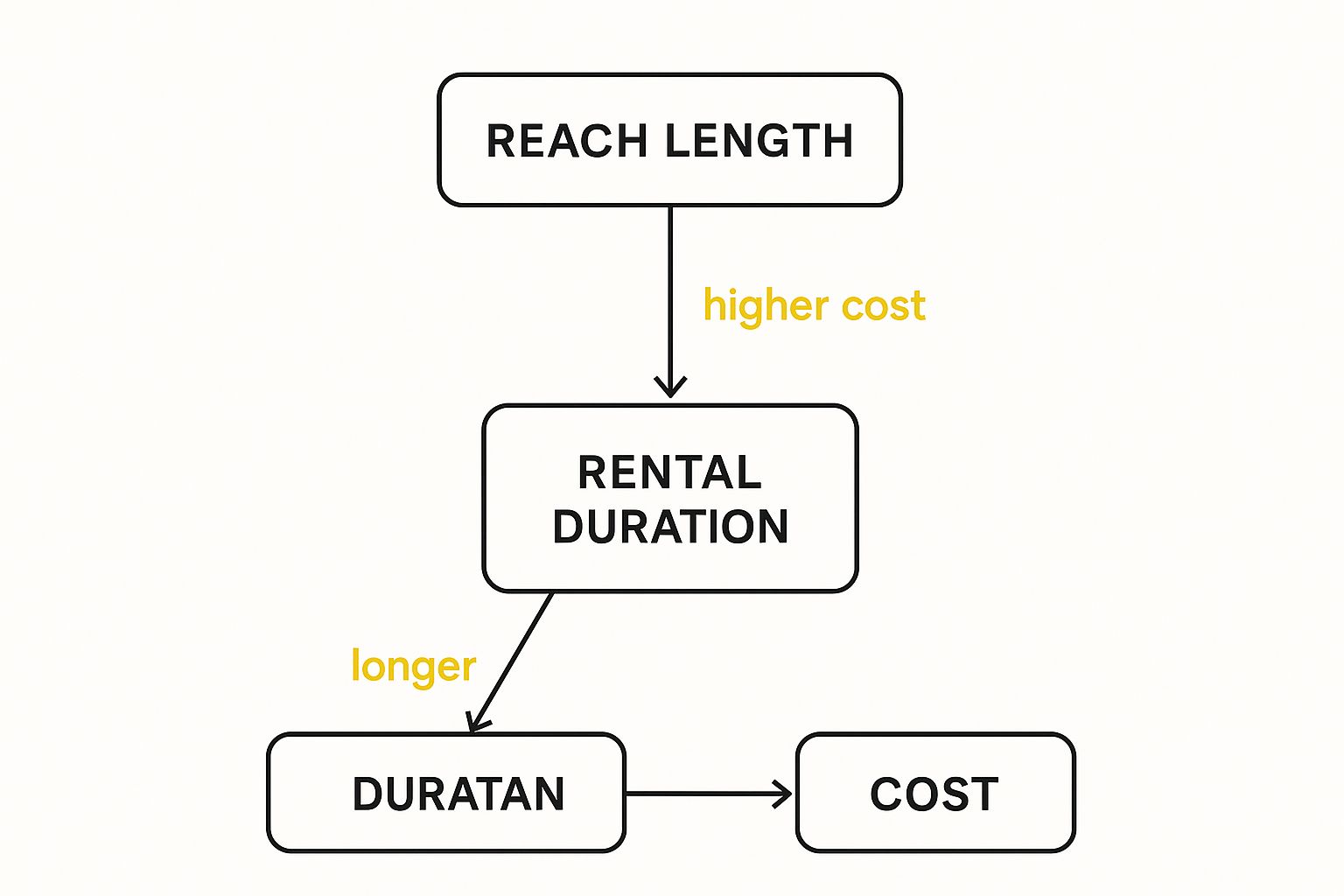

As this shows, the greater the reach your project demands, the more specialized the machine becomes. This naturally affects the rental cost and can influence the overall project timeline.

The decision to rent a long reach excavator is a strategic one. You're investing a bit more upfront in specialized equipment to prevent much larger costs down the road, costs that come from project delays, safety incidents, or failing to meet environmental regulations.

Ultimately, it comes down to using the right tool for the job. When your project involves serious distance, depth, or tricky access, trying to make a standard machine work isn't a cost-saving move, it's an operational risk. Choosing a long reach excavator rental ensures you have the capability you need, exactly when you need it.

Where Long Reach Excavators Make the Difference

A long reach excavator isn't just a bigger machine, it's a problem-solver. Think of it as a strategic tool that tackles specific, often expensive, challenges on a job site. Its real value shines in situations where a standard excavator would require massive site prep or simply couldn't get the job done safely.

It's no surprise that demand for specialized equipment like this is on the rise. The construction equipment rental market was recently valued at around $141.41 billion USD, and experts see it climbing to $179.21 billion by 2030. Earthmoving gear, including long reach models, accounts for a whopping 41% of that rental revenue. This highlights just how much the industry depends on renting the right tool for the right job.

Precision Dredging and Waterway Maintenance

Dredging is one of the most common jobs you'll see a long reach excavator on. Whether it's clearing out canals, rivers, or ponds, removing sediment and debris is crucial for everything from flood control to keeping waterways navigable.

Imagine trying to do this with a standard excavator. You would be stuck on the bank, only able to reach a few feet out. That often means bringing in barges or building costly temporary roads into the water. A long reach excavator, on the other hand, can sit comfortably on solid ground and systematically clean out the channel from a distance.

This completely changes the game. What was once a major logistical headache becomes a controlled, efficient task. It dramatically cuts down on environmental disruption and can shave a significant amount of time off the project schedule.

For projects where the machine needs to get into the water, you can learn more about specialized equipment for dredging that can handle tough wetland conditions.

Safe and Controlled Demolition

When you are taking down a building or a bridge, safety is everything. A long reach excavator gives an operator the ability to dismantle a structure piece by piece, all from a safe distance well outside the collapse zone.

This controlled method beats traditional demolition techniques hands down:

- Keeps Everyone Safe: By keeping your crew and expensive gear far from falling debris, you slash the risk of accidents.

- Systematic Takedown: The operator can carefully pick apart the structure, guiding where everything falls and protecting nearby properties.

- Less Dust and Mess: When you add an attachment like a shear or a pulverizer, the machine can process materials right then and there, which helps keep dust down.

This level of precision is invaluable, especially in crowded urban areas or on complex industrial sites where you cannot afford any mistakes.

Environmental Cleanup and Remediation

Environmental projects are all about precision. When you need to remove contaminated soil from a sensitive riverbank, wetland, or industrial site, the last thing you want to do is cause more damage.

This is where a long reach excavator truly excels. It can reach over fragile ground or containment barriers to carefully scoop out hazardous material, all without the machine itself ever touching the sensitive area. This surgical approach prevents cross-contamination and protects delicate habitats, making sure the cleanup is done right and meets all regulatory standards.

The Financial Case for Renting Specialized Equipment

When you're dealing with specialized machines, the sticker price is just the beginning of the story. While buying equipment might look like a solid long-term investment on paper, the hidden costs can eat into your project's profitability faster than you would think. This is where a strategic long reach excavator rental often makes a lot more sense for most jobs.

The financial argument for renting is pretty straightforward. You're turning a massive capital expense into a predictable, manageable operating cost. That move frees up a serious amount of cash that you can put to better use elsewhere in your business, whether that's hiring top-tier operators or having the liquidity to bid on more contracts.

The Hidden Costs of Ownership

Buying a machine as specialized as a long reach excavator means committing to a lot more than just the initial purchase. These ongoing expenses can really start to pile up.

- Steep Capital Investment: Let's be blunt: a new long reach excavator can cost hundreds of thousands of dollars. That's a huge chunk of capital to have tied up in a single piece of iron.

- Relentless Maintenance: This is not a pickup truck you can take to any mechanic. Specialized gear requires specialized care. You have to budget for routine servicing, unexpected repairs, and parts, not to mention having skilled technicians on call.

- Complex Logistics and Storage: Getting an oversized machine to and from a job site is a project in itself, often requiring special permits and transport. And when it is idle? You need a secure, spacious yard to store it, which is another line item on your expense sheet.

- Depreciation: Heavy equipment starts losing value the second it rolls off the lot. It's a depreciating asset that directly impacts your company's balance sheet over time.

When you add it all up, the true cost of ownership is a continuous financial drain, not a one-time payment.

The Strategic Advantages of Renting

Choosing to rent a long reach excavator turns these financial headaches into strategic wins. It gives you the power to bring in the exact machine you need, for the exact time you need it, without the long-term financial hangover.

This rental-first approach is quickly becoming the norm in our industry for a good reason. The global construction equipment rental market was valued at around $213.68 billion and is expected to hit $280.13 billion by 2030. You can dig into the numbers behind these global equipment rental market trends. This massive shift is happening because companies need to be more agile and financially savvy, making the old model of owning everything less and less practical.

Renting provides immediate access to the latest, most efficient models without the capital drain. You pay for the equipment only when it's generating revenue for you, which optimizes cash flow and minimizes financial risk.

And while we're focused on excavators here, this same logic applies across the board. Renting is a smart way to manage costs and boost efficiency for everything on a job site, from heavy machinery to essential facilities and other construction site rental solutions. At the end of the day, renting leads to predictable project costs and zero long-term maintenance liability, which helps you bid more accurately and manage your finances better.

How to Choose the Right Long Reach Excavator

Picking the right machine for a long reach excavator rental goes way beyond simply finding the one with the longest boom. It is a critical decision that will make or break your project's efficiency, safety, and budget. When you successfully match an excavator’s capabilities to your job site's unique demands, you set the stage for a smooth operation. Get it wrong, and you're looking at a costly mismatch.

The whole process boils down to translating your project's needs into hard machine specifications. You have to look past the impressive numbers on a spec sheet and really understand how they'll play out in the field. Metrics like reach, digging depth, and bucket capacity are your starting point, but they're just the beginning of the story.

Translating Project Needs into Machine Specs

First things first: get out your tape measure. You need to know the exact distance you need the machine to cover. If you're dredging a pond, that means measuring from a solid patch of ground to the absolute furthest point you need to work on. Pro tip: always add a little buffer to your measurement. This ensures the excavator can operate comfortably without being stretched to its absolute limit.

Next up is digging depth. How far down does the work need to happen? A machine’s maximum digging depth is a non-negotiable spec for jobs like deep foundation work or cleaning out heavily sedimented canals.

Finally, you have to think about the material you're moving. The bucket capacity, typically measured in cubic yards, dictates how much you can scoop in a single pass. A bigger bucket is great for moving a lot of earth quickly, but that extra weight can compromise the machine's stability when the boom is fully extended. It's a constant balancing act between speed and safety.

A common mistake is getting fixated on horizontal reach alone. Remember, an excavator’s lifting power drops dramatically the further the boom extends. You have to be certain the machine can not only get to the work area but also lift the required load once it’s there.

Before you even pick up the phone to call a rental company, it's wise to have a clear picture of your project's demands. Answering a few key questions upfront will make the entire rental process smoother and ensure you get the right piece of equipment for the job.

Project Checklist for Selecting Your Excavator Rental

| Consideration | Key Questions to Ask | Why It Matters |

|---|---|---|

| Reach & Depth | What is the maximum horizontal distance? What is the maximum vertical depth? | This determines the required boom length and stick configuration. Underestimating leads to project delays. |

| Lifting Capacity | What is the heaviest load you need to lift at the furthest point? | The excavator's capacity decreases at full reach. You need a machine that can handle the load safely. |

| Material Type | What are you digging (e.g., soil, sand, rock, demolition debris)? | This dictates the necessary bucket type (e.g., dredging, rock) and overall machine power. |

| Site Conditions | What is the ground like (e.g., firm soil, mud, swamp, water)? | Ground conditions determine the need for a standard, wide-track, or amphibious undercarriage. |

| Logistics | How will the machine be transported to and from the site? Are there any access limitations? | Large equipment requires specialized transport and clear access routes, which can impact your budget and timeline. |

| Attachments | What specific tasks need to be performed (e.g., digging, grading, demolition)? | The primary task dictates the necessary attachment, from buckets and grapples to shears and pulverizers. |

Thinking through these points will not only help you clarify your needs but also empower you to have a much more productive conversation with your rental partner.

Evaluating Site Conditions and Undercarriage Options

The ground supporting the excavator is just as critical as the work happening at the end of the boom. The conditions on your site will directly influence the type of undercarriage you will need. For projects on firm, stable ground, a standard tracked undercarriage is perfect, it provides plenty of stability and traction.

However, many long reach jobs happen in messy environments. Think swamps, marshes, or saturated wetlands. In these situations, a standard machine is out of the question. This is where specialized amphibious undercarriages are a game-changer. These unique systems allow the excavator to actually float and navigate through water and soft terrain, making previously inaccessible sites completely workable.

When you're discussing a rental, be ready to give a very detailed description of your site. That information is exactly what an experienced rental partner, like Wilco Manufacturing, needs to recommend the ideal machine configuration for a successful project.

Matching Attachments to the Task

The excavator is really just the platform, the attachment at the end of the boom is what does the actual work. Different jobs demand different tools.

- Dredging Bucket: Built with perforations that let water drain out, making it lighter and far more efficient for pulling up submerged sediment.

- Grading Bucket: A wider, smoother bucket designed for finishing slopes or creating a clean, level surface on riverbanks and hillsides.

- Grapple or Clamshell: Your go-to for demolition work or for carefully handling large, awkwardly shaped debris.

- Shears or Pulverizers: These are heavy-duty demolition tools that can slice through steel or crush concrete from a safe distance.

The magic happens when you pair the right excavator with the perfect attachment. To get a better idea of what is possible, you can check out some of the most popular Wilco Marsh Runner attachments to see how versatile this equipment can be. Making an informed choice from the start is how you ensure you have the power, reach, and tooling to get the job done right.

Getting Your Rental Sorted: Process and People

Renting a long reach excavator should not be a headache. It's a straightforward part of your project planning, and it usually kicks off with a detailed chat about your job site. A good rental partner will want to know everything: your specific needs, the ground conditions, and your project schedule. Think of them as part of your team, helping you double-check that the machine’s reach, digging depth, and undercarriage are a perfect fit for the work ahead.

Once you have landed on the right machine, you'll move on to the rental agreement. This is where you will find all the important details laid out, rental period, rates, insurance needs, and who handles maintenance and transport. Getting everything clear at this stage is key to avoiding surprises later and making sure everyone's on the same page.

It's Not Just a Bigger Machine: The Operator Factor

A long reach excavator isn't simply a standard digger with a longer arm. The physics are completely different. That extended boom creates a unique center of gravity, which means the person in the cab needs a whole different level of skill and spatial awareness. Operating one of these safely and efficiently takes a real feel for leverage, balance, and load limits, especially when that boom is stretched all the way out.

Put an inexperienced operator in the seat, and you are asking for trouble. At best, you will get slow, inefficient work. At worst, you risk a serious safety incident. The operator has to constantly read the ground conditions and judge the weight of every single scoop to keep the machine from tipping over.

This is why the person in the cab is just as important as the machine itself. An expert operator doesn't just dig faster, they protect your investment, your timeline, and most importantly, your team. Their experience is a crucial component of risk management on any job site.

Making Sure You Have the Right Pro for the Job

A top-notch rental company provides more than just the equipment, they get that the human element is non-negotiable. When you work with a true specialist, you're not just getting a well-maintained machine. You are also tapping into a network of certified, seasoned operators who live and breathe long reach applications.

This ensures you have a professional on-site who knows exactly how to push the machine to its productive limits while keeping safety as the top priority. For jobs in tricky or sensitive areas, a full-service rental can be a game-changer. You can see how Wilco handles these complex projects by looking at our options for amphibious excavators for rent. Taking this route protects your project from the major risks that come with an unqualified operator, setting you up for a successful finish.

Maximizing Safety and Efficiency On-Site

Getting the right long reach excavator rental to your job site is just the beginning. The real secret to a successful project lies in how you use that machine once it's there. It's all about combining powerful equipment with smart, disciplined practices to ensure everything runs safely, quickly, and profitably.

Before that excavator even rolls off the trailer, your site preparation has to be on point. This is non-negotiable. Your crew needs to establish a stable, level platform for the machine to work from. A solid base is the foundation for everything that follows, dramatically reducing the risk of tipping when the boom is stretched to its limit and the machine is most vulnerable.

Best Practices for On-Site Operations

Once the excavator is in place, a few key techniques can make a world of difference in your daily output.

Smart positioning is everything. You want to minimize how often you have to track the machine, as every move burns fuel and eats up valuable time. A skilled operator will aim to get as much done as possible from one spot before repositioning.

It's also about digging with a plan. Instead of just scooping wherever, adopting a systematic digging pattern leads to a much cleaner finish and more consistent progress. Whether you're dredging a waterway or grading a slope, a methodical approach prevents costly rework and helps keep the project on track.

Of course, some environments demand specialized gear. For work in saturated soil or wetlands, a standard machine just won't cut it. You'll need something like an amphibious excavator, also known as a marsh buggy. You can get more details on what a marsh buggy is and where to get one to tackle those unique, challenging jobs.

A Constant Focus on Safety

Throughout the entire project, safety has to be the top priority. This commitment starts every single day with pre-operation checks and a deep understanding of the machine's specific load charts and reach capabilities.

Every operator must know the machine's tipping point and respect its operational boundaries. Pushing a long reach excavator beyond its designed limits is a direct path to a serious incident, compromising both personnel and equipment.

Clear, constant communication between the operator, spotters, and ground crew is also crucial. Everyone needs to be in sync to coordinate movements and adapt to any changes on the site.

Beyond the machine itself, overall site security is a major piece of the puzzle. It's often a good idea to think about measures like enhancing construction site safety with specialized camera rentals to keep an eye on the entire work area. By blending smart operational habits with strict safety protocols, you will truly get the most out of your rental.

Got Questions? We've Got Answers

When you're looking into renting a long reach excavator, a few common questions usually pop up. Getting straight answers to these is key to making sure you're getting the right machine for your project and feeling confident in your decision. Let's tackle some of the most frequent ones we hear.

What is the Real Cost of Renting a Long Reach Excavator?

There's no simple, flat rate for a long reach rental. The final price tag really depends on a few key things: the machine's size and how far it can reach, how long you'll need it on-site, and the logistics of getting it to you.

As a general rule, a daily rate will be higher than a weekly or monthly one. For longer jobs, booking by the week or month offers much better value. The best way to get a solid number for your budget is to ask for a custom quote that's built around your specific project details and location.

Can These Machines Actually Work in Water or Swamps?

A standard long reach excavator is built to operate on solid ground. But what if your job site is a swamp, marsh, or shallow waterway? That's when you bring in a specialized amphibious undercarriage.

This is where our expertise at Wilco Manufacturing really comes into play. By mounting the excavator on an amphibious undercarriage, the machine can float and move through saturated or submerged ground. This setup is a game-changer for many dredging and environmental cleanup projects.

How Far in Advance Should I Book a Rental?

The lead time can change depending on what's available and where your project is located. For specialized gear like long reach and amphibious excavators, it is always smart to plan ahead, think several weeks, not days.

Reaching out to your rental provider early in the planning stage is your best bet. It locks in the machine you need and gives everyone enough time to coordinate delivery without a hitch, keeping your project right on schedule.

The success of your project hinges on having the right tool for the job when you need it. For specialized amphibious and long reach excavator solutions, you can count on the team at Wilco Manufacturing to provide reliable equipment and the know-how to tackle your toughest challenges.

Ready to get started? Contact us today to talk about your project and get a quote.

Learn more about our equipment and rental options at Wilco Manufacturing